Mesoporous manganese oxide nanometer material capable of removing ozone and formaldehyde in air at room temperature simultaneously

A nanomaterial, manganese oxide technology, applied in the field of mesoporous manganese oxide nanomaterials, the above-mentioned mesoporous materials, and the preparation of mesoporous materials, can solve the problems of expensive catalysts and the like, and achieve excellent economy, high stability, and good removal ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

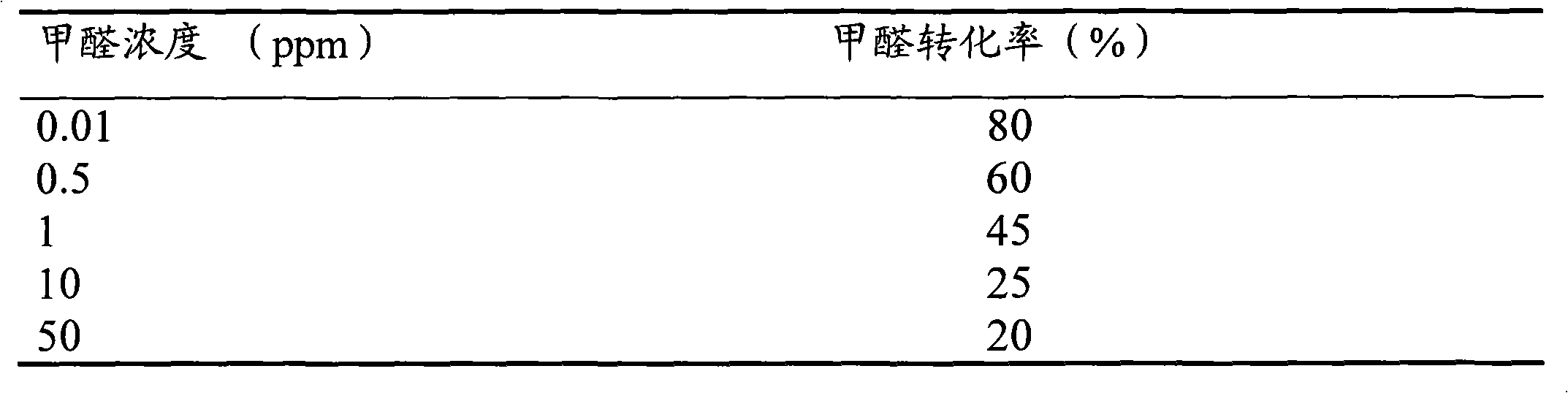

Examples

Embodiment 1

[0029] Preparation of Mesoporous Manganese Oxide Nanomaterials. Add a certain amount of PVP to NaMnO containing 0.01mol 4 , KMnO 4 Or add 40ml trioctylamine to 250ml aqueous solution of soluble manganese salt under constant stirring to obtain a sol, then seal and crystallize at 50°C for 24h, then transfer the sol to a kettle with a Teflon liner , hydrothermal at 100°C for 24h, the resulting product was repeatedly washed with deionized water and ethanol, then placed in an electric vacuum oven and dried in vacuum at 100°C for 24h; finally put into a muffle furnace and calcined at 200-500°C for 6h The template agent is removed, and the obtained powder is the mesoporous manganese oxide sample.

[0030] Preparation of Mesoporous Manganese Oxide Nanomaterials Supported on Honeycomb Ceramic Support. A certain amount of mesoporous manganese oxide nanomaterial is weighed, and a certain proportion of deionized water and binder are added. According to the requirements of viscosity an...

Embodiment 2

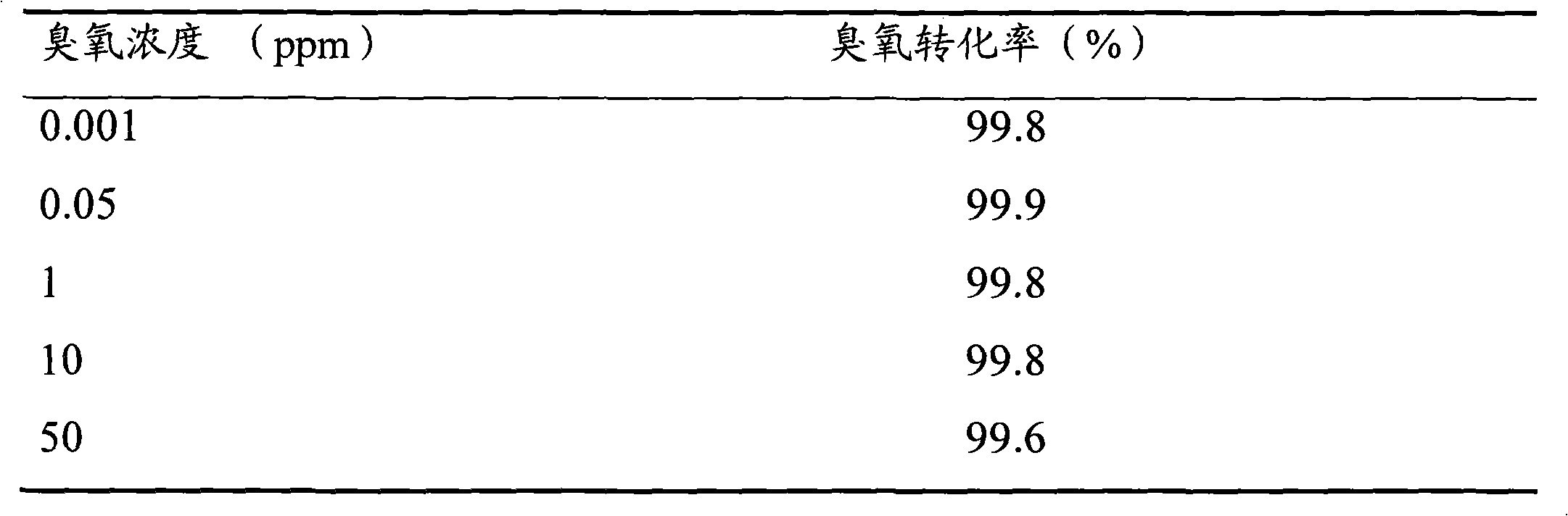

[0035] The preparation of mesoporous manganese oxide nanomaterials is the same as in Example 1

[0036] Before the catalyst performance test, the catalyst was not treated in any way. The powder catalyst was pressed into tablets and crushed to make 0.25-0.50mm particle samples, and then 0.2g particle samples were placed in a glass tube, at room temperature (20°C) and relative Under the condition of humidity of 50%, pass through containing 0.001-50mg / m 3 For ozone air, the wind speed is 2.5m / s. Ozone at the reactor outlet was detected with an ozone analyzer. . The results are shown in Table 2.

[0037] Table 2. Test results for catalytic ozone removal.

[0038]

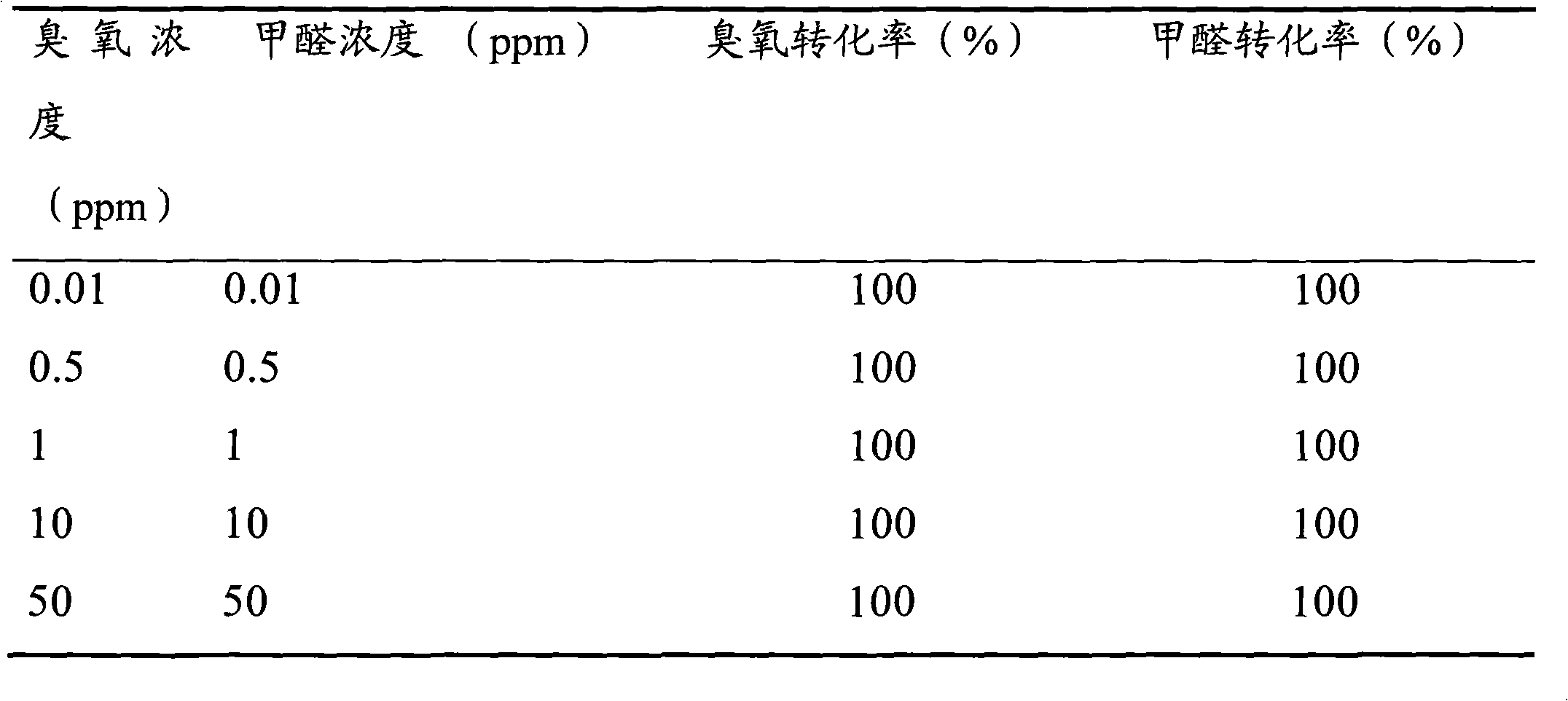

[0039] Example three

[0040] The preparation of mesoporous manganese oxide nanomaterials is the same as in Example 1

[0041] Before the catalyst performance test, the catalyst was not treated in any way. The powder catalyst was pressed into tablets and crushed to make 0.25-0.50mm particle samples, and then 0.2g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com