Preparation method of multiple-effect compound type corrosion and scale inhibitor

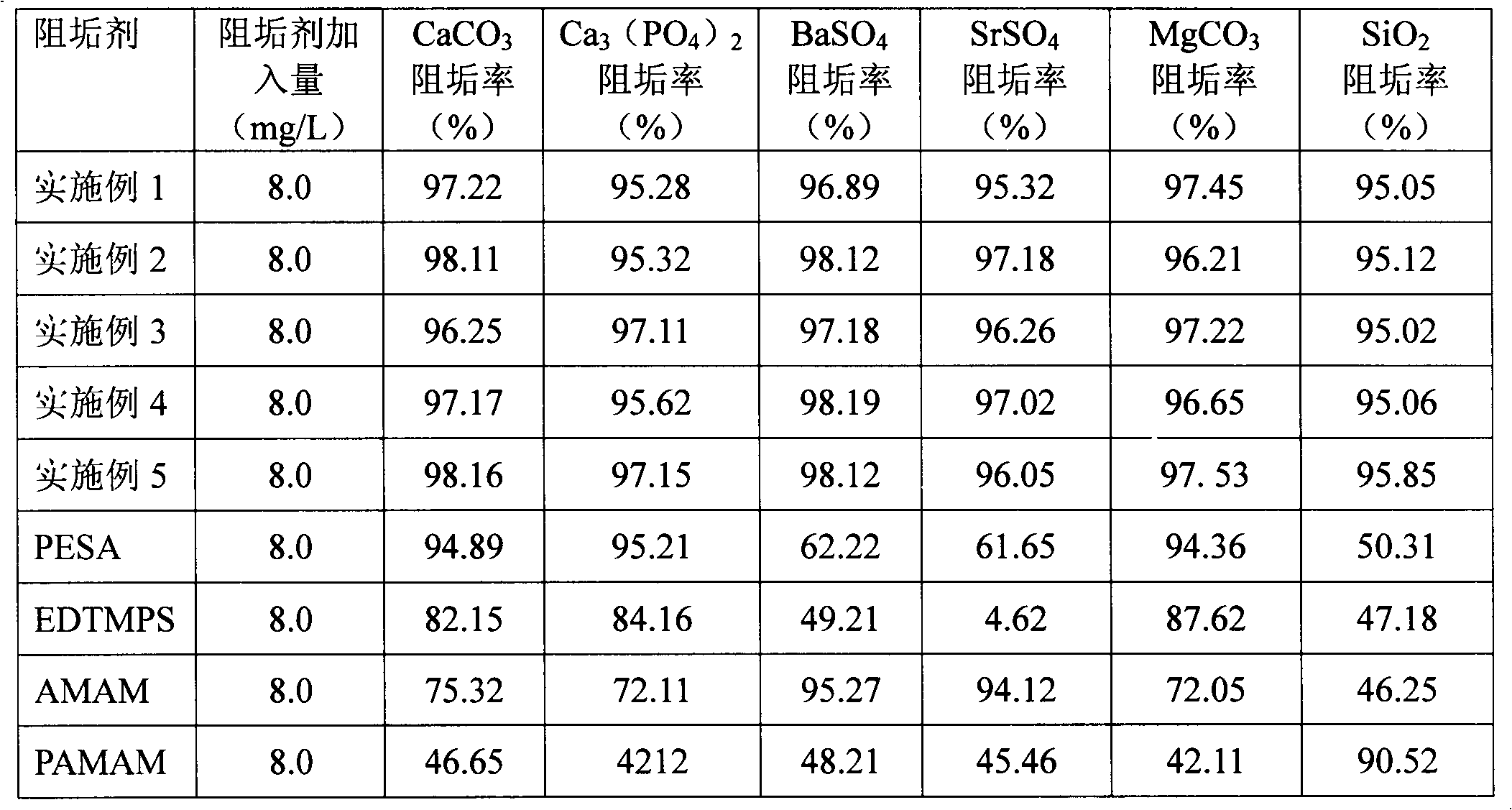

A corrosion and scale inhibitor, composite technology, applied in the preparation of phosphorus-free, barium-strontium composite corrosion and scale inhibitors, biodegradable green environmental protection corrosion and scale inhibitors, can solve the problem of narrow application range, barium Strontium has problems such as poor scale inhibition effect and weak scale inhibition ability, and achieves the effect of less dosage, good product stability and strong scale inhibition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Synthesis of itaconic acid-maleic acid-acrylic acid-methyl acrylate polymer: It is characterized in that in the reactor, add 13g itaconic acid, 35g maleic anhydride, add 50mL water, stopper, stir, and keep the temperature at 50°C , dissolve, react 40mim;

[0017] (2) Mix 25mL of acrylic acid and 30mL of methyl acrylate evenly, then dissolve 3g of ammonium persulfate in 12mL of water and add to the above solution. In the solution, after the dropwise addition, raise the temperature to 70°C for constant temperature reaction for 2 hours, then raise the temperature to 85°C for constant temperature reaction for 4 hours, cool to about 50°C, and use 50% sodium hydroxide solution to adjust the pH to be weakly alkaline. The obtained yellow transparent viscous liquid is itaconic acid-maleic acid-acrylic acid-methyl acrylate polymer;

[0018] (3) Add 10mL polyepoxysuccinic acid, 5mL ethylenediamine tetramethylene phosphoric acid, 15mL itaconic acid-maleic acid-acrylic acid-met...

Embodiment 2

[0020] (1) Synthesis of itaconic acid-maleic acid-acrylic acid-methyl acrylate polymer: It is characterized in that in the reactor, add 25g itaconic acid, 30g maleic anhydride, add 60mL water, stopper, stir, and keep the temperature at 55°C , dissolve, react 30mim;

[0021] (2) Mix 35mL of acrylic acid and 45mL of methyl acrylate evenly, then dissolve 5g of ammonium persulfate in 15mL of water and add to the above solution. In the solution, after the dropwise addition, raise the temperature to 75°C for constant temperature reaction for 2 hours, then raise the temperature to 90°C for constant temperature reaction for 4 hours, cool to about 50°C, and adjust the pH to weak alkaline with 50% sodium hydroxide solution. The obtained yellow transparent viscous liquid is itaconic acid-maleic acid-acrylic acid-methyl acrylate polymer;

[0022] (3) Add 20mL polyepoxysuccinic acid, 10mL ethylenediaminetetramethylene phosphoric acid, 25mL itaconic acid-maleic acid-acrylic acid-methyl acr...

Embodiment 3

[0024] (1) Synthesis of itaconic acid-maleic acid-acrylic acid-methyl acrylate polymer: It is characterized in that in the reactor, add 10g itaconic acid, 35g maleic anhydride, add 35mL water, stopper, stir, and keep the temperature at 50°C , dissolve, react 60mim;

[0025] (2) Mix 20mL of acrylic acid and 30mL of methyl acrylate evenly, then dissolve 4g of ammonium persulfate in 12mL of water and add to the above solution. In the solution, after the dropwise addition, raise the temperature to 75°C for 1.5 hours, then raise the temperature to 90°C for 5 hours, cool to about 50°C, and adjust the pH to weak alkaline with 50% sodium hydroxide solution , the obtained yellow transparent viscous liquid is itaconic acid-maleic acid-acrylic acid-methyl acrylate polymer;

[0026] (3) Add 20mL polyepoxysuccinic acid, 12mL ethylenediamine tetramethylene phosphoric acid, 35mL itaconic acid-maleic acid-acrylic acid-methyl acrylate polymer and 10mL dendritic polyamide-amine to the reactor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com