High-intensity magnesite cement board and preparation method thereof

A cement board and high-strength technology, applied in the field of building materials, can solve the problems of people's living hazards, easy peeling of the wall, and no resistance to freezing, and achieve the effects of good compactness, simple construction, and good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

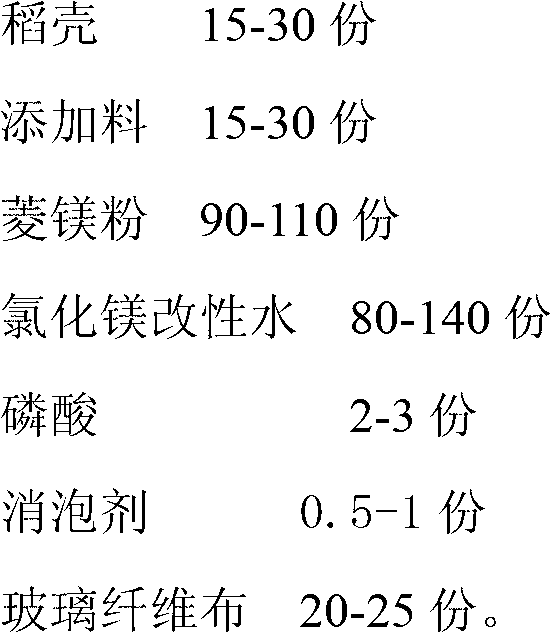

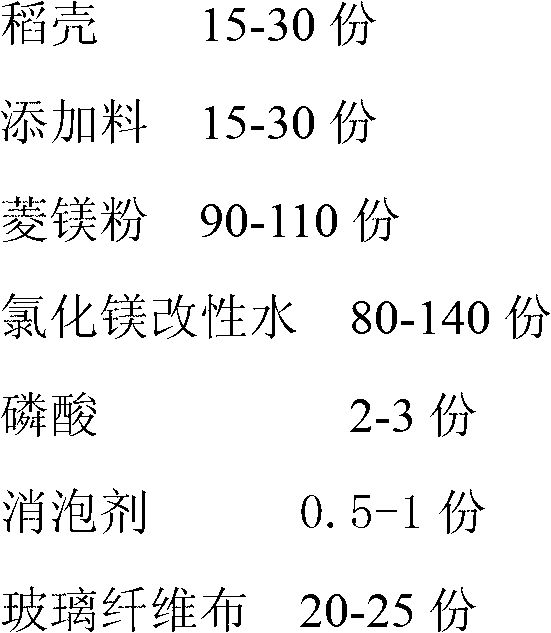

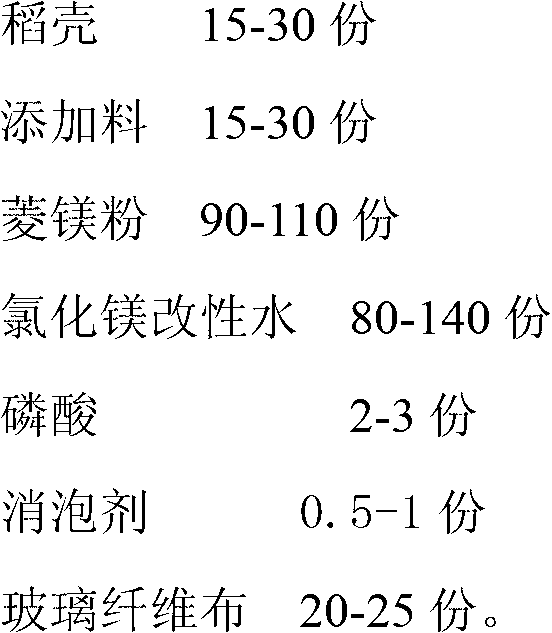

[0031] A preparation method of magnesite high-strength cement board, the steps are:

[0032] (1) Take 23 kg of rice husk, 26 kg of bluestone powder, and 10 kg of saw foam, start the machine and stir for 5 minutes, then add 110 kg of magnesium chloride modified water, the glass magnesium specific gravity of the modified water is 27 degrees; 100 kg of magnesium powder, after 10 minutes, add 1.5 kg of phosphoric acid, 0.3 kg of defoamer, and form a mixed slurry after 5 minutes.

[0033] ⑵Adjust the thickness of the molding machine, such as six layers of glass fiber cloth, then put it into the mold, add a layer of glass fiber cloth into the mold, and fill the glass fiber cloth with mixed slurry, the thickness of the mixed slurry is 0.2cm, Vibrate the rolling plate to fully mix the glass fiber cloth with the mixed slurry; then lay the second, third, fourth, and fifth layers, and add mixed slurry to the glass fiber cloth until the sixth layer is covered Fiberglass cloth, when opera...

Embodiment 2

[0037] A preparation method of magnesite high-strength cement board, the steps are:

[0038] (1) Take 25 kg of rice husk, 28 kg of bluestone powder, and 5 kg of fly ash, start the machine and stir for 5 minutes, then add magnesium sulfate modified water, the glass magnesium specific gravity of the modified water is 29 degrees; 100 kg of magnesium powder, after 10 minutes, add 1.5 kg of phosphoric acid, 0.3 kg of defoamer, and form a mixed slurry after 5 minutes.

[0039] ⑵Adjust the thickness of the molding machine, such as four layers of glass fiber cloth, and then put it into the mold, add a layer of glass fiber cloth into the mold, and add mixed slurry on the glass fiber cloth, the thickness of the mixed slurry is 0.2cm, Vibrate the rolling plate to fully mix the glass fiber cloth with the mixed slurry; then lay the second and third layers, and fill the mixed slurry on the glass fiber cloth respectively until the fourth layer of glass fiber cloth is covered. , keep vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com