Method for preparing punicalagin molecularly imprinted polymer monolithic column by utilizing in-situ polymerization method

A punicalagin molecule, in-situ polymerization technology is applied in the field of in-situ polymerization to prepare a punicalagin molecularly imprinted polymer monolithic column, which can solve the problems of difficult separation and purification, low content of active components, complex system and the like, and avoids column packing. The procedure, the preparation process is simple, and the effect of simplifying the experimental process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Preparation and separation of punicalagin and its structural analogues on a molecularly imprinted monolithic column for punicalagin

[0019] Molecularly imprinted monolithic column with punicalagin as template was synthesized by in situ polymerization, and its retention performance was evaluated by connecting it to high performance liquid chromatography under appropriate chromatographic conditions. Synthetic reaction conditions and processing method are as follows:

[0020] Preparation of punicalagin molecularly imprinted monolithic column by in situ polymerization:

[0021] a. According to the mass number of punicalagin-imprinted monolithic column synthesized in a stainless steel column, accurately weigh the template molecule as punicalagin 3.00%, the functional monomer as acrylamide 2.37%, and the cross-linking agent as ethyl dimethacrylate Glycol ester 33.03%, porogen is polystyrene dissolved in tetrahydrofuran solution 56.50% (wherein the concentration of polystyre...

Embodiment 2

[0025] Embodiment 2 (contrast)

[0026] Separation of punicalagin and its structural analogues on a blank monolithic column

[0027] In order to investigate the retention of punicalagin and its structural analogues on non-imprinted columns, a blank column without template punicalagin was synthesized as a control. The specific operation steps are as follows:

[0028] Except that the template molecule punicalagin was not added, a non-imprinted blank column was synthesized with the same method and experimental conditions as in Example 1. After polymerization is complete, rinse with THF to remove residual porogen and unreacted reagents from the monolith.

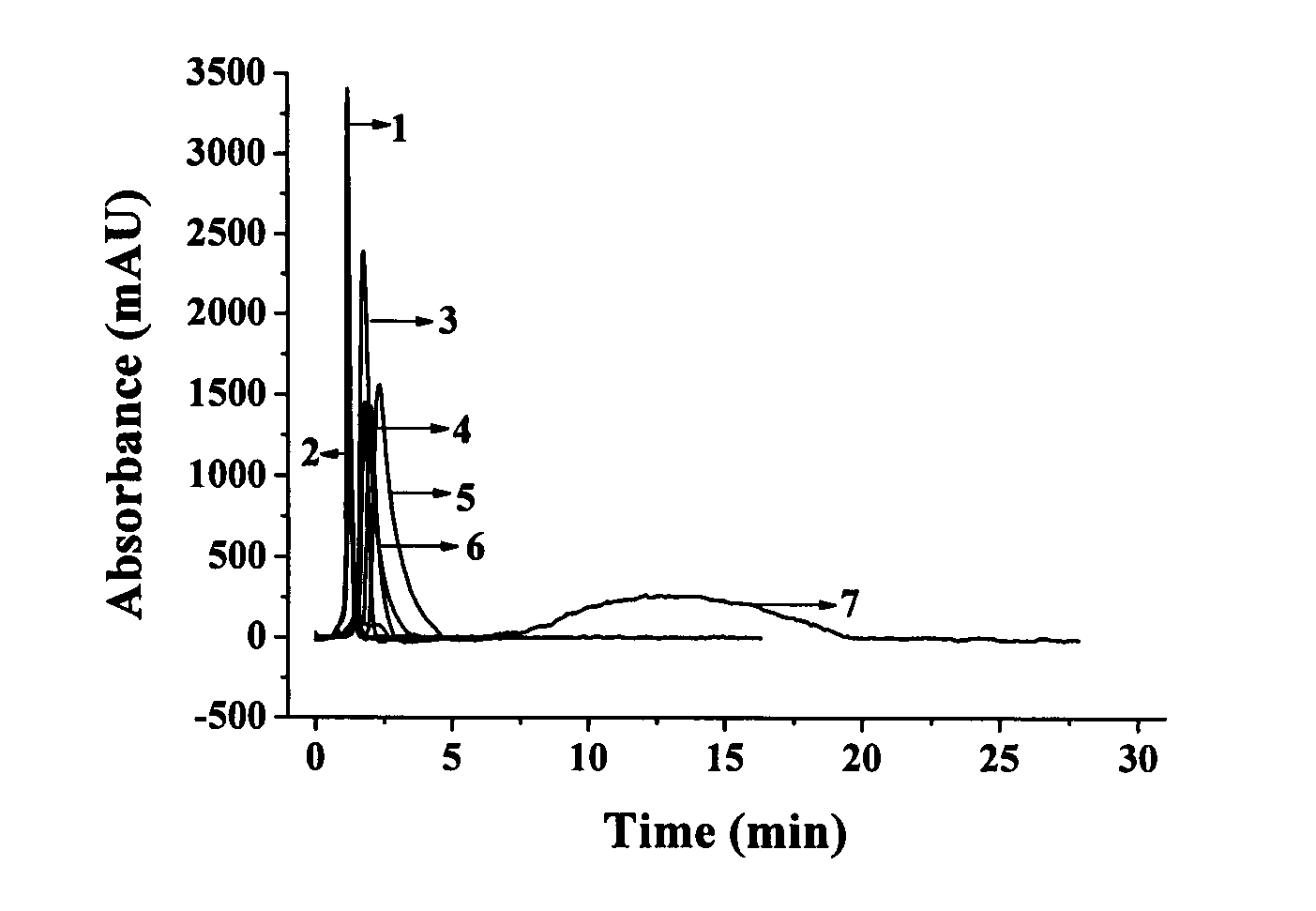

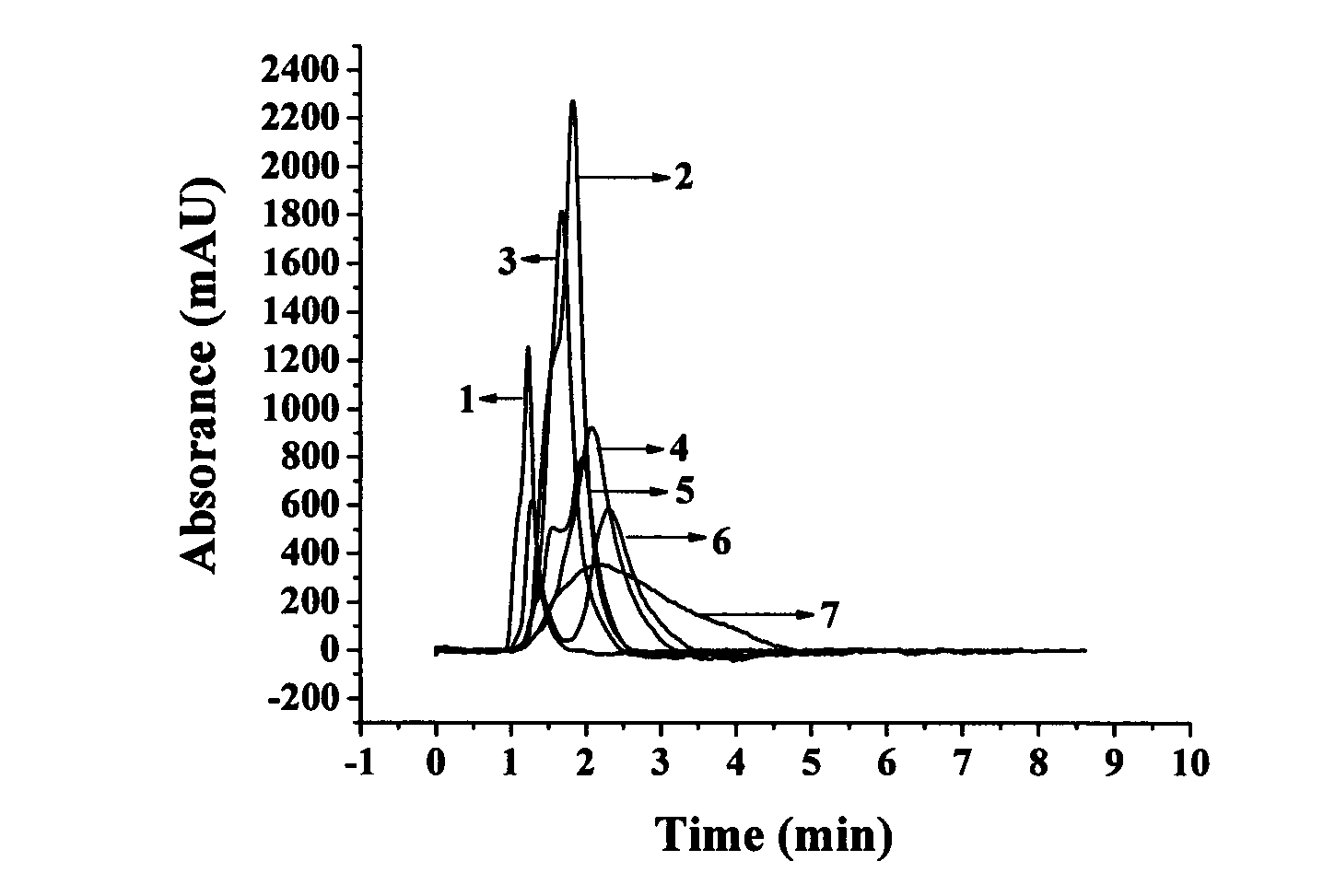

[0029] The chromatographic evaluation is the same as the investigation of the imprinted column in Example 1, that is, under the same mobile phase conditions, by measuring the retention time t of punicalagin and its analogues R and retention time t of acetone 0 , to calculate the retention factor k'.

[0030] The results sho...

Embodiment 3

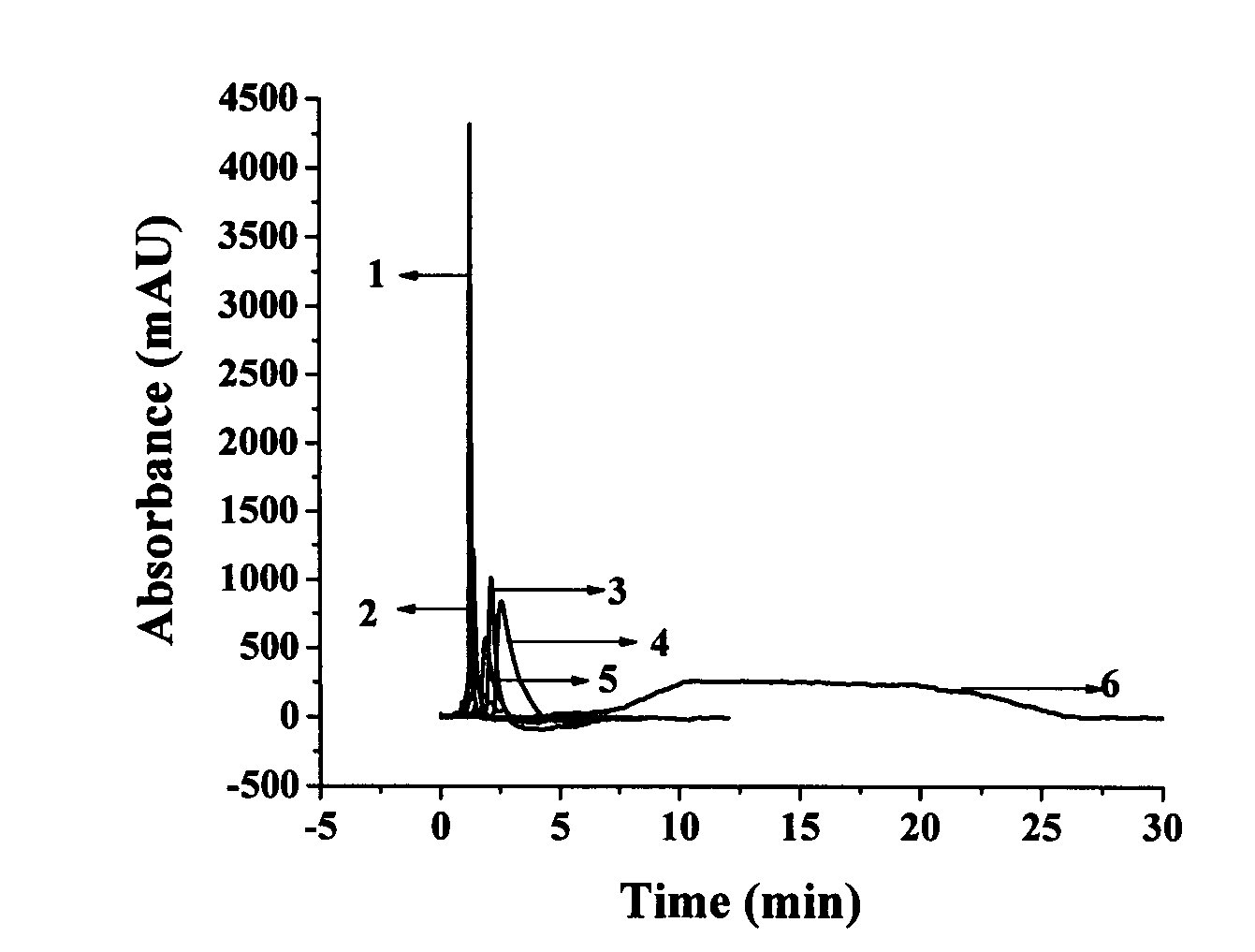

[0033] Preparation of punicalagin molecularly imprinted monolithic column by in situ polymerization:

[0034] a. According to the mass number of punicalagin-imprinted monolithic column synthesized in a stainless steel column, accurately weigh the template molecule as punicalagin 3.19%, the functional monomer as acrylamide 2.51%, and the cross-linking agent as ethyl dimethacrylate Glycol ester 29.03%, porogen is 59.87% polystyrene dissolved in tetrahydrofuran solution (wherein the concentration of polystyrene dissolved in tetrahydrofuran solution is 40mg / ml), then add isooctane 4.96%, initiator is azo Diisobutyronitrile 0.44% mixed, placed in a sonicator, sonicated for 20 minutes to make it uniform and clarified, then transferred to a clean stainless steel column (100×4.6mm I.D.), degassed by sonication for 15 minutes, and the stainless steel tube Seal both ends of the column, and react in a constant temperature water bath at a temperature of 60°C for 32 hours;

[0035] b. Rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com