Titanium oxide nano powder and manufacturing method thereof

A nano-powder, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, nanotechnology, etc., can solve the problems of uniformity to be improved, expensive production equipment, unfavorable mass and continuous production, etc., and achieve particle size distribution easily , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] Preparation of Octahedral Titanium Dioxide Nanopowders

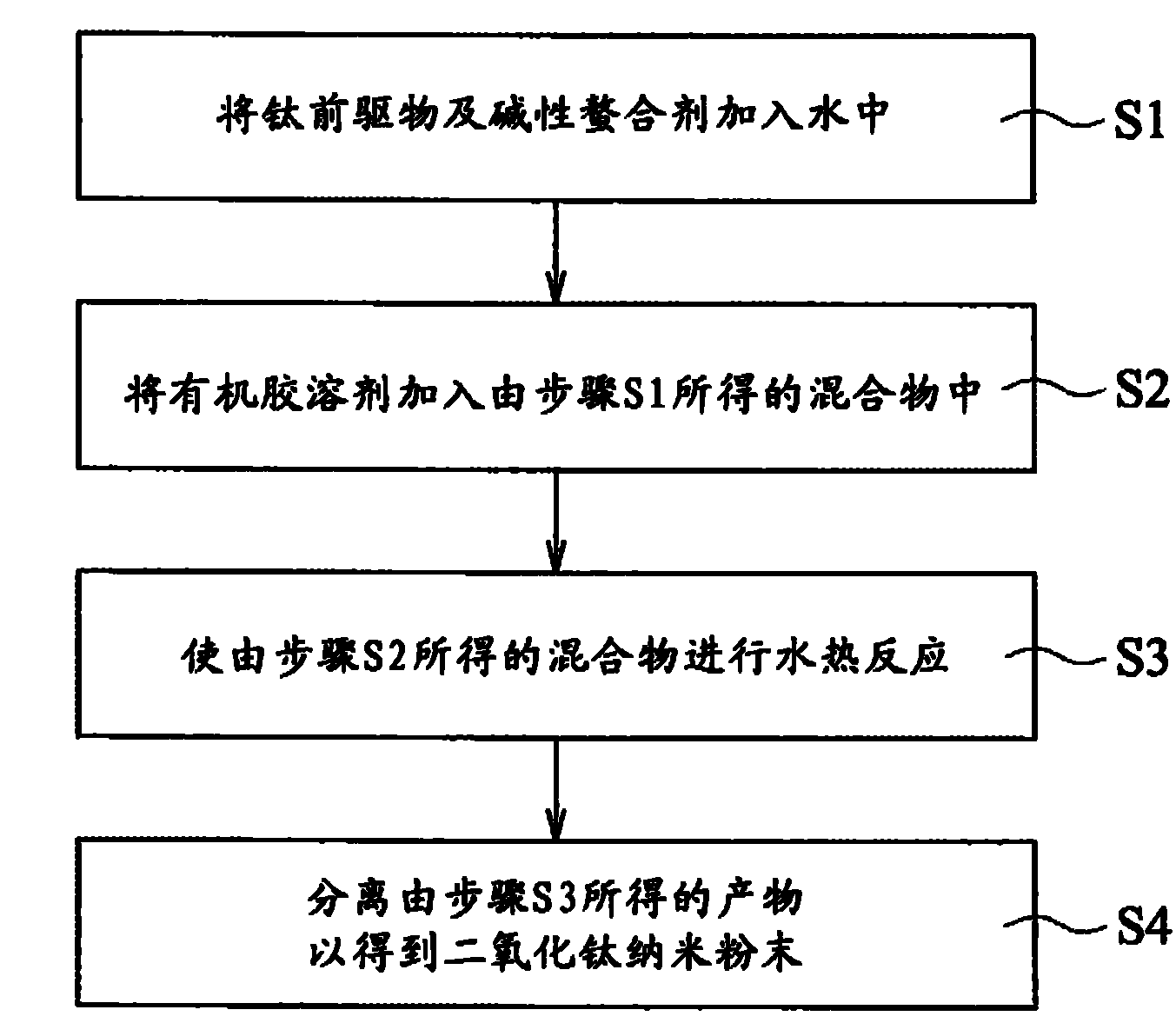

[0016] The invention mainly utilizes the sol-gel method and the hydrothermal method to manufacture regular octahedral titanium dioxide nanometer powder. figure 1 A method for producing the titanium dioxide nanopowder of the present invention is shown. In step S1, titanium precursor and alkaline chelating agent are added into water. The titanium precursor can be titanium tetrachloride, titanium isopropoxide, titanium butoxide or titanium alkoxide. And the alkyl group of the titanium alkoxide may have 1 to 6 carbon atoms. The basic chelating agent can be an alcohol amine, such as triethanolamine (Triethanolamine). Step S1 can be performed under an inert gas, such as nitrogen or argon. Moreover, the reaction condition of step S1 may be 4-15° C. and continuous stirring for about 24-72 hours.

[0017] In step S2, an organic peptizer is added to the mixture obtained in step S1. The organic peptizer can be an amine...

Embodiment 1

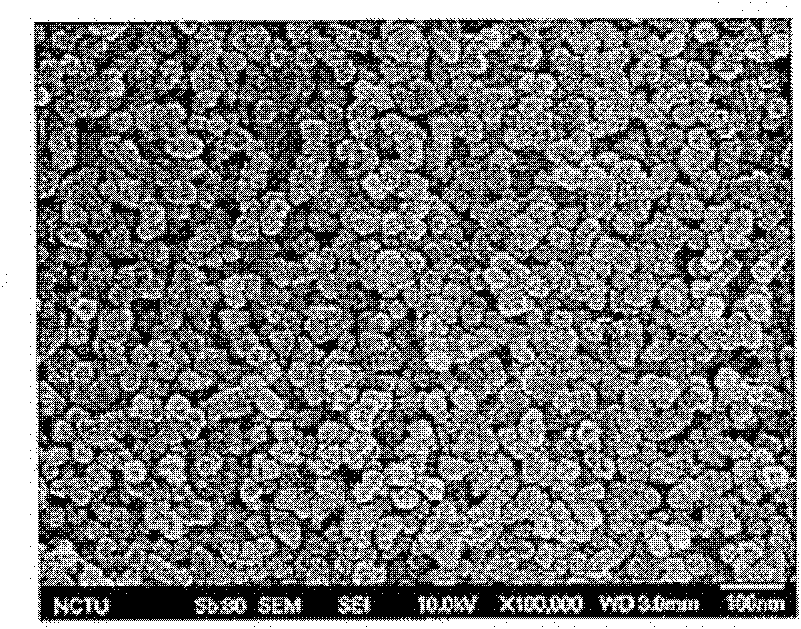

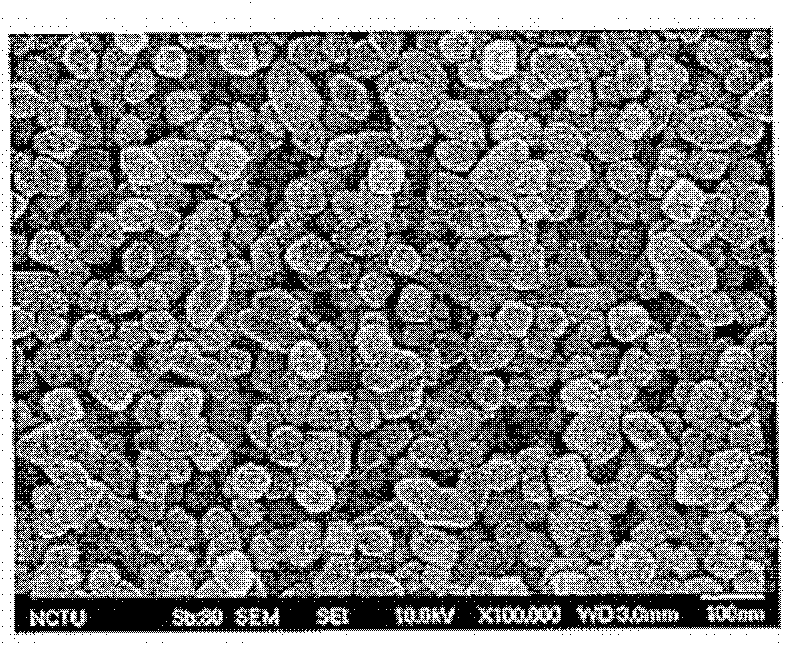

[0022] While stirring 100 mL of deionized water at high speed, add titanium isopropoxide (titanium isopropoxide) and triethanolamine (Triethanolamine) into deionized water dropwise at a rate of 1 to several drops per second (the molar ratio of the two is about 1 to 1), a titanium precursor solution can be obtained, and nitrogen or argon can be selectively introduced. Continue stirring for about 24 to 72 hours; then add shape-controlled diethylamine (Diethylamine), and increase the temperature to 100°C and continue stirring for about 24 to 72 hours; then increase the temperature to 230-270°C and continue Stir for about 2 to 72 hours for hydrothermal reaction. The obtained mixture is then collected as powder by means of filtration or centrifugation. Wash the above powder with deionized water at least three times to remove residual solvent, triethanolamine or diethylamine; then dry it in an oven with a temperature between 60 and 500°C, thus obtaining the regular octahedral titan...

Embodiment 2

[0029] Mix 6 g of the aforementioned regular octahedral titanium dioxide nanopowder with 1 mL of acetic acid and stir for three minutes; add 5 mL of deionized water and stir for 3 minutes to make it evenly mixed; then add 15 mL of ethanol, 20 g of terpineol and 30 g of ethyl cellulose Afterwards, stir for 12 hours to make it uniformly dispersed, and the manufacture of the regular octahedral titanium dioxide nano-slurry is completed.

[0030] By screen printing, the aforementioned regular octahedral titanium dioxide nano-slurry is coated on a transparent conductive glass substrate, and sintered at high temperature to remove organic substances. The sintering temperature is between 300 and 600°C, and the sintering time is between 1 to 5 hours; then cooled to room temperature, a regular octahedral titanium dioxide nano-film can be formed on the substrate with a thickness of 1 to 10 microns, which can be used for example as a transparent electrode of a solar cell. The hardness of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com