Phase-change energy-storage inorganic foam fireproof thermal-insulation board and preparation method thereof

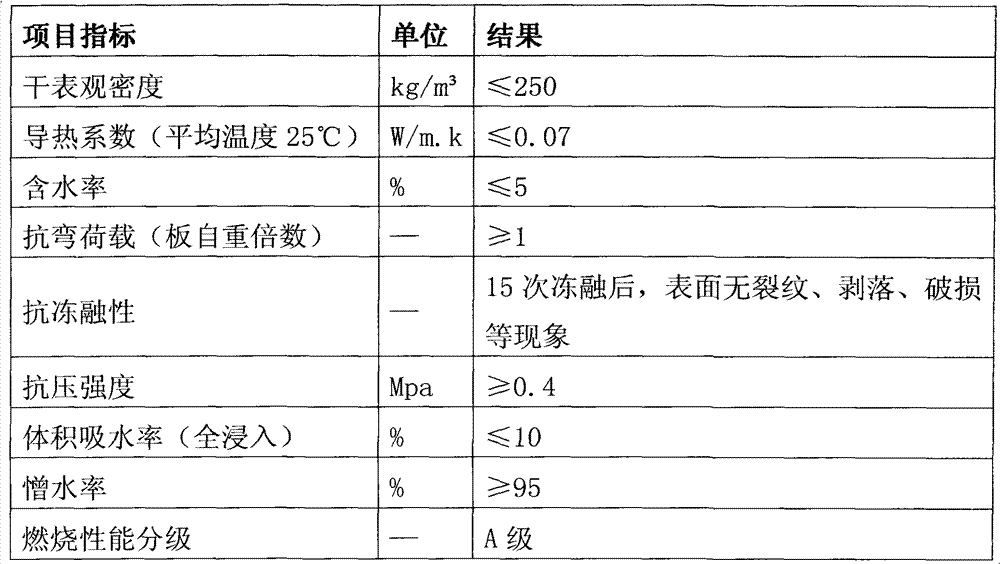

A fireproof insulation board and inorganic foaming technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of unsatisfactory thermal insulation performance, high thermal conductivity of thermal insulation boards, and difficulty in industrial production. Excellent thermal insulation performance, simple formula, easy to make and easy to obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

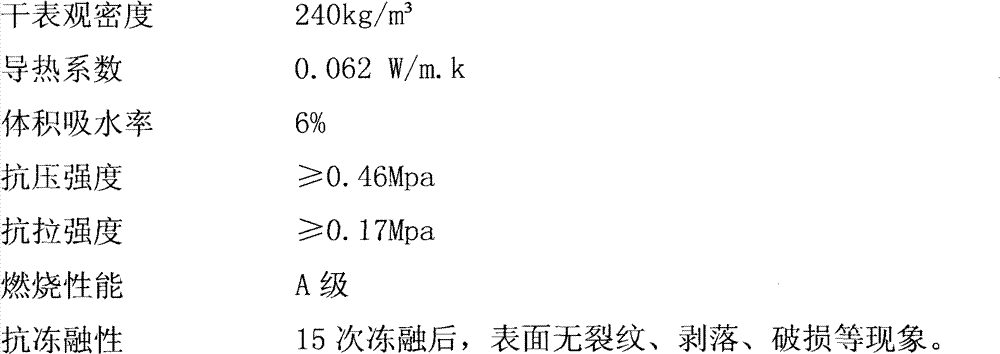

Embodiment 1

[0039] Embodiment 1: A phase-change energy storage inorganic foamed fireproof insulation board, including ultrafine cement slurry and foaming liquid material, the weight ratio of ultrafine cement slurry and foaming liquid material is 1:0.5.

[0040] The superfine cement paste comprises the following raw materials in parts by weight:

[0041] Ultrafine cement 100; ultrafine fly ash 30; phase change material 20; active micro-mineral powder 20; rubber powder 2; fiber 1; water-repellent agent 0.5; water-repellent agent 0.5;

[0042] Among them, the superfine cement has a specific surface area of 700m 2 / kg Portland cement, superfine fly ash has a specific surface area of 500m 2 / kg ultra-fine fly ash, the phase change material is a mixture of n-octadecanoic acid, Glauber’s salt, and volcanic zeolite powder, the active micro-mineral powder is micro-silica powder, the rubber powder is redispersible latex powder, and the fiber is 6mm poly Acrylic fiber, the water repellent is s...

Embodiment 2

[0057] Embodiment 2: A phase-change energy storage inorganic foamed fireproof insulation board, including ultra-fine cement slurry and foaming liquid material, the weight ratio of ultra-fine cement slurry and foaming liquid material is 1:0.5.

[0058] The superfine cement paste comprises the following raw materials in parts by weight:

[0059] Ultrafine cement 80; ultrafine fly ash 20; phase change material 40; active micro-mineral powder 20; rubber powder 3; fiber 0.8; water-repellent agent 0.4; hydrophobic agent 0.3;

[0060] Among them, the superfine cement has a specific surface area of 1000m 2 / kg Portland cement, superfine fly ash has a specific surface area of 800m 2 / kg ultra-fine fly ash, the phase change material is a mixture of n-octadecanoic acid, Glauber’s salt, and volcanic zeolite powder, the active micro-mineral powder is micro-silica powder, the rubber powder is redispersible latex powder, and the fiber is 10mm poly Acrylic fiber, the water repellent is ...

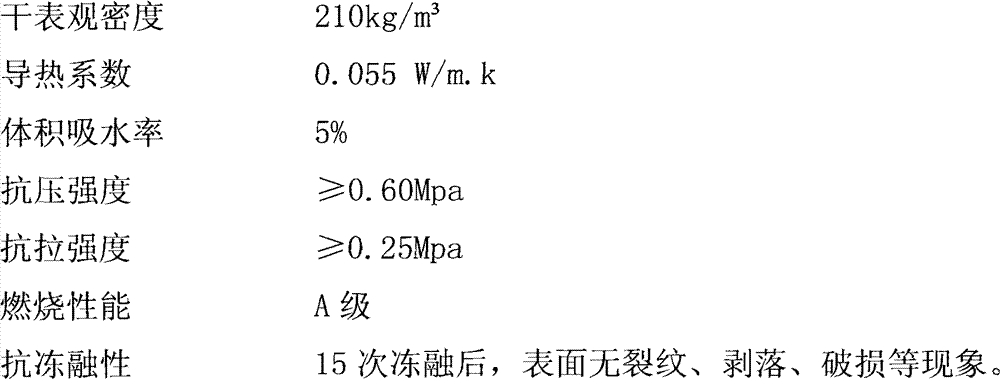

Embodiment 3

[0075] Embodiment 3: A phase-change energy storage inorganic foamed fireproof insulation board, including ultra-fine cement slurry and foaming liquid material, the weight ratio of ultra-fine cement slurry and foaming liquid material is 1:0.5.

[0076] The superfine cement paste comprises the following raw materials in parts by weight:

[0077] Ultrafine cement 60; ultrafine fly ash 50; phase change material 30; active micro-mineral powder 20; rubber powder 3; fiber 0.8; water repellent agent 0.4; water repellent agent 0.3;

[0078] Among them, the superfine cement has a specific surface area of 800m 2 / kg Portland cement, superfine fly ash has a specific surface area of 600m 2 / kg ultra-fine fly ash, the phase change material is a mixture of n-octadecanoic acid, Glauber’s salt, and volcanic zeolite powder, the active micro-mineral powder is micro-silica powder, the rubber powder is redispersible latex powder, and the fiber is 7mm poly Acrylic fiber, the water repellent i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com