Fermentation medium and fermentation method of aflatoxin B1

A fermentation medium and aflatoxin technology, applied in the field of fermentation engineering, can solve the problems of low spore vigor, low toxin production, long growth (recovery) cycle, etc., to achieve high spore vigor, easy access to raw materials, and short culture cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

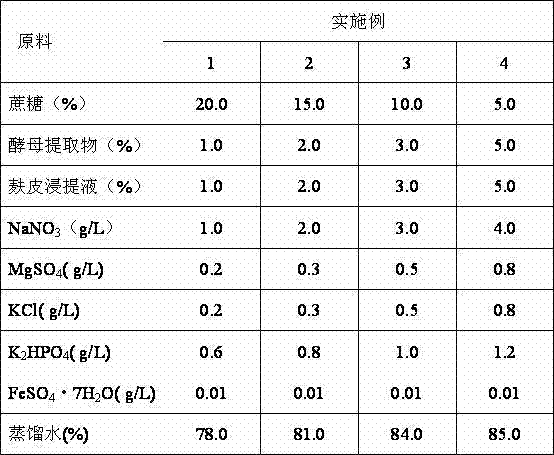

[0021] The preparation of embodiment 1-4 Aspergillus flavus growth-promoting nutrient solution

[0022] After mixing the components shown in Table 1, adjust the pH value of the mixed solution to 5.5-7.0 with hydrochloric acid solution.

[0023] Table 1

[0024]

[0025] Now take Example 2 as an example to prepare 1 L of growth-promoting nutrient solution. Weigh 150g sucrose, 20g yeast extract, 20ml bran extract, 2gNaNO 3 , 0.3gMgSO 4 , 0.3gKCl, 0.8gK 2 HPO 4 , 0.01gFeSO 4 .7H 2 O, 810ml of distilled water was placed in a 2000ml Erlenmeyer flask, after heating to dissolve all the raw materials, use 5mol / L hydrochloric acid to adjust the pH value to 5.5-7.0. After pH adjustment, cover with a cotton plug, and sterilize at 121-123°C, 0.12MPa, for 20min. After cooling in the biosafety cabinet, the growth-promoting nutrient solution was prepared.

[0026] The preparation method of the bran extract is as follows (the same below): take 1 unit weight of bran and place it i...

Embodiment 5-8

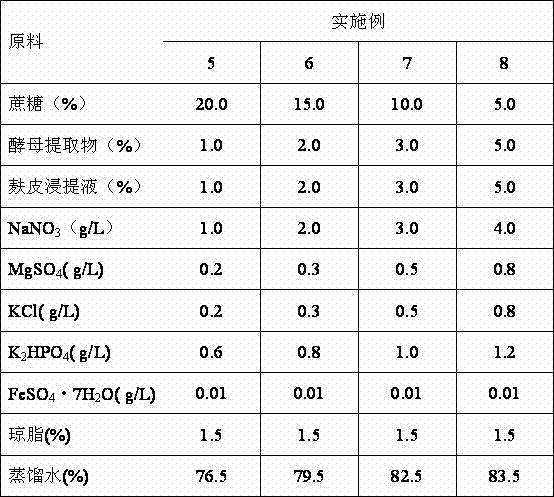

[0027] Embodiment 5-8 Preparation of aspergillus flavus recovery medium

[0028] A recovery medium for Aspergillus flavus. After mixing the components shown in Table 2, the pH value of the mixed solution is adjusted to 5.5-7.0 with hydrochloric acid solution.

[0029] Table 2

[0030]

[0031] Now take the Aspergillus flavus recovery medium formula in Example 6 as an example to prepare 1L recovery medium. Weigh 150g sucrose, 20g yeast extract, 20ml bran extract, 2gNaNO 3 , 0.3gMgSO 4 , 0.3gKCl, 0.8gK 2 HPO 4 , 0.01gFeSO 4 .7H 2O, 15g of agar powder, 795ml of distilled water, placed in a 2000ml Erlenmeyer flask, after heating to dissolve all the raw materials, use 5mol / L hydrochloric acid to adjust the pH value to 5.5-7.0. After pH adjustment, cover with a cotton plug, and sterilize at 121-123°C, 0.12MPa, for 20min. In a biological safety cabinet, the sterilized resuscitation medium was not solidified at 60°C, and placed upside down in a sterilized 10 cm diameter p...

Embodiment 9-12

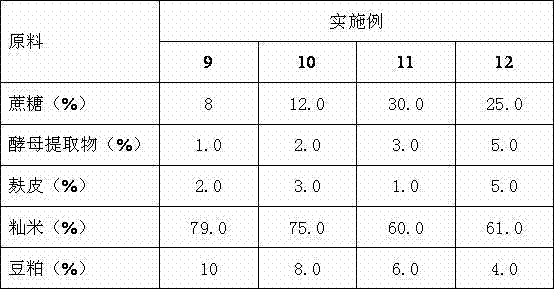

[0034] The preparation of embodiment 9-12 Aspergillus flavus solid fermentation medium

[0035] According to the recipe in Table 3, prepare the required medium.

[0036] table 3

[0037]

[0038] Raw material preparation: crush indica rice, soybean meal and bran, the particle size is required to pass through a 20-mesh standard sieve, but not through a 40-mesh standard sieve, that is, between 20 and 40 mesh.

[0039] Now take the components of Example 10 as an example to prepare 1 kg of solid fermentation medium. Weigh 120g of sucrose, 20g of yeast extract, 30g of bran, 750g of indica rice, 80g of soybean meal, and another 80ml of distilled water, mix the above materials evenly, put them in a 3000ml Erlenmeyer flask, cover with a cotton plug, and store at 121-123°C , 0.12MPa, sterilization for 20min. In a biological safety cabinet, pour the sterilized solid medium upside down in a sterilized Erlenmeyer flask with a thickness of 1cm, or a load of 50g / 500ml Erlenmeyer fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com