Preparation method of beta-cyclodextrin inclusion compound-containing electrospun fiber

A technology of cyclodextrin inclusion compound and electrospun fiber, which is applied in fiber treatment, fiber chemical characteristics, conjugated synthetic polymer artificial filament, etc., can solve uneven dispersion of drugs, easy pollution of the environment, agglomeration and burst release and other problems, to achieve the effect of smooth and uniform surface, low cost and increased solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of β-cyclodextrin inclusion compound: Dissolve indomethacin in an appropriate amount of acetone or ethyl acetate, and slowly add to β-cyclodextrin saturated aqueous solution at 70°C (n 吲哚美辛 :n β-环糊精 =1:2), and stirred at constant temperature for 4 hours. After standing for 6 hours, stand in the refrigerator at 4°C for 12 hours, filter, wash, and dry to constant weight.

[0028] (2) Configuration of spinning solution: dissolve the water-soluble polymer polyvinylpyrrolidone in water, configure a 12wt% solution, add 20wt% (relative to the polymer) cyclodextrin inclusion compound obtained in step ①, continue Stir for 6 hours to obtain a spinning solution.

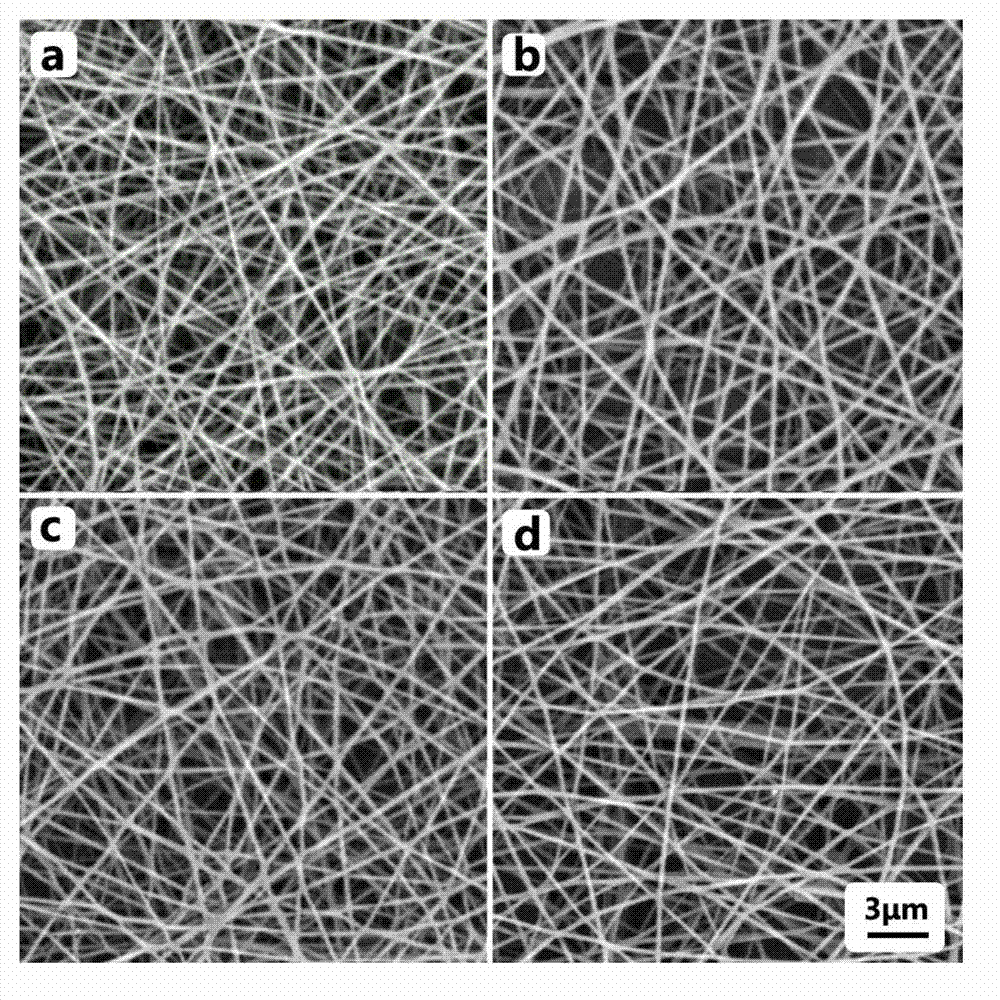

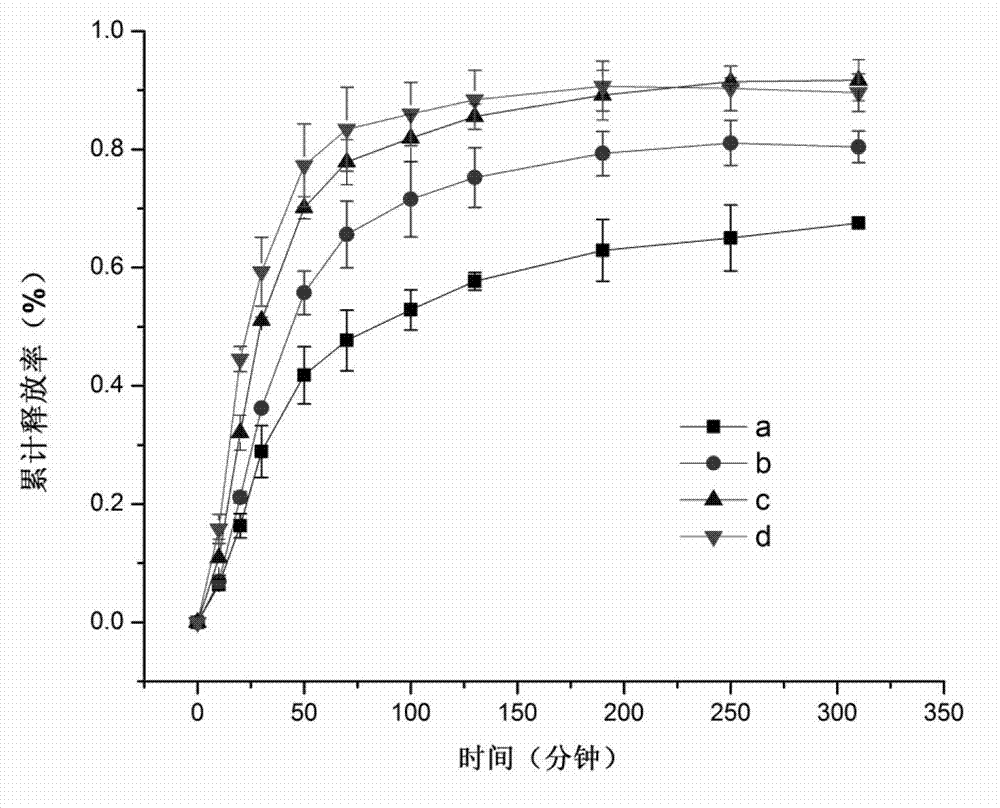

[0029] (3) Electrospinning: 10Kv, 1.5ml / h, humidity 40%, receiving distance 15cm. The diameter of the obtained fiber is 150-400nm, the release of indomethacin is slow, and the half-life is close to 24 hours.

Embodiment 2

[0031] (1) Preparation of β-cyclodextrin inclusion compound: Dissolve curcumin in an appropriate amount of acetone, and slowly add it to β-cyclodextrin saturated aqueous solution at 45°C (n 姜黄素 :n β-环糊精 =1:2), reflux at 50°C for 4 hours, lower to room temperature and continue to stir for 8 hours, stand at 4°C for 12 hours, filter, wash, and dry to constant weight.

[0032] (2) Configuration of spinning solution: dissolve the water-soluble polymer polyvinyl alcohol in water at 90°C, prepare a 10wt% solution, add 20-50wt% (relative to the polymer) cyclodextrin inclusion compound obtained in step ①, Stirring was continued for 8 hours to obtain a spinning solution.

[0033] (3) Electrospinning: 15Kv, 0.5ml / h, humidity 35%, receiving distance 20cm.

Embodiment 3

[0035] (1) Preparation of β-cyclodextrin inclusion compound: Mix β-cyclodextrin and water at a molar ratio of 1:2, add phenobarbital and mix well (n 苯巴比妥 :n β-环糊精 =1:1), ground into paste, dried at 35°C, washed and then dried to obtain β-cyclodextrin inclusion compound.

[0036] (2) Configuration of spinning solution: Dissolve water-soluble polymer polyvinyl alcohol in water at 90°C, prepare 8wt% solution, add 30wt% (relative to polymer) cyclodextrin inclusion compound obtained in step ①, and continue stirring A spinning solution was obtained in 10 hours.

[0037] (3) Electrospinning: 20Kv, 1ml / h, humidity 45%, receiving distance 25cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com