Oxide for semiconductor layer of thin-film transistor, sputtering target, and thin-film transistor

A thin-film transistor and oxide technology, applied in the manufacture of transistors, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of reduced conductivity, change in switching characteristics, and reduced reliability, and achieve excellent switching characteristics, excellent stress tolerance, Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

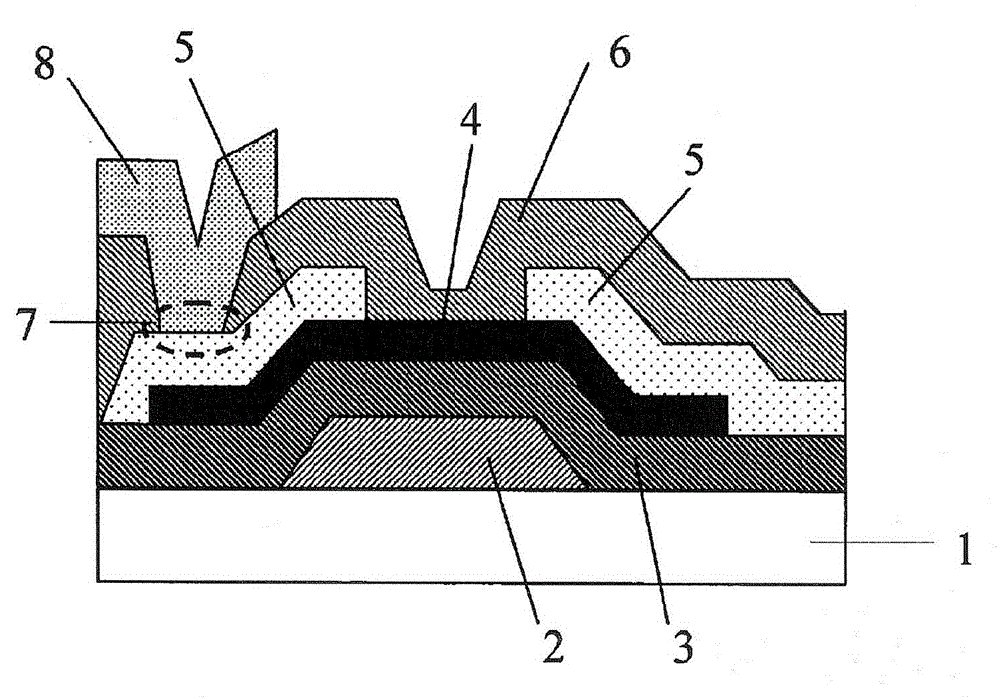

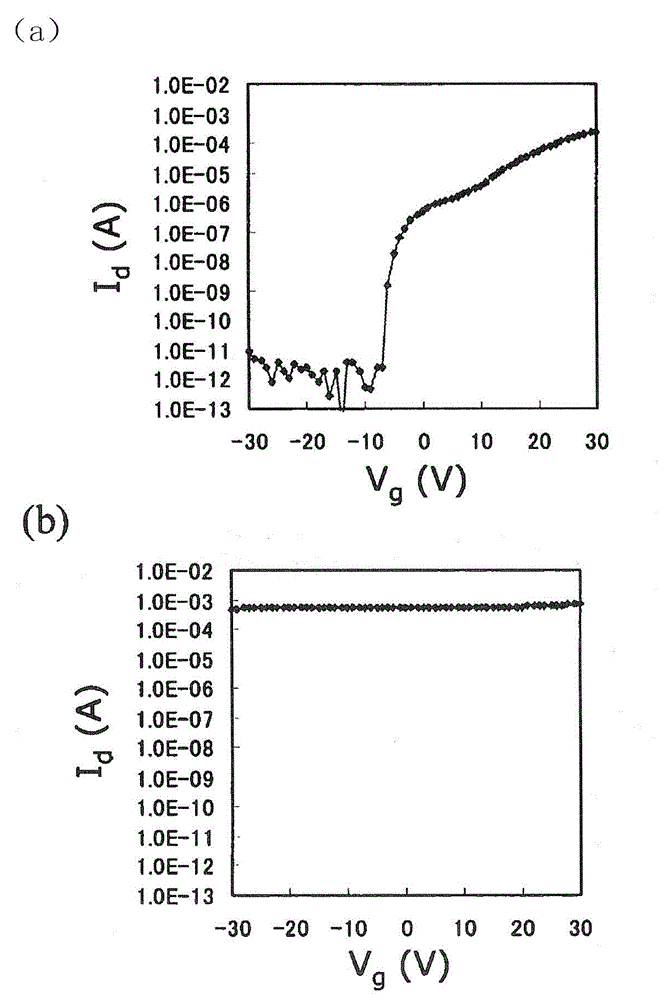

[0075] Based on the aforementioned method, the production figure 1 For the thin film transistor (TFT) shown, the TFT characteristics before and after the formation of the protective film were evaluated.

[0076] First, on a glass substrate (Igre 2000 manufactured by Corning Corporation, 100 mm in diameter x 0.7 mm in thickness), as a gate electrode, a Ti thin film of 100 nm and a gate insulating film of SiO were sequentially deposited. 2 (200nm). A pure Ti sputtering target was used for the gate electrode, and a film was formed by a DC sputtering method at a film forming temperature: room temperature, a film forming power: 300W, a carrier gas: Ar, and a gas pressure: 2mTorr. In addition, the gate insulating film uses the plasma CVD method with a carrier gas: SiH 4 and N 2 A mixed gas of O, a film forming power: 100 W, and a film forming temperature: 300° C. were used to form a film.

[0077] Next, oxide thin films having various compositions described in Table 1 were forme...

Embodiment 2

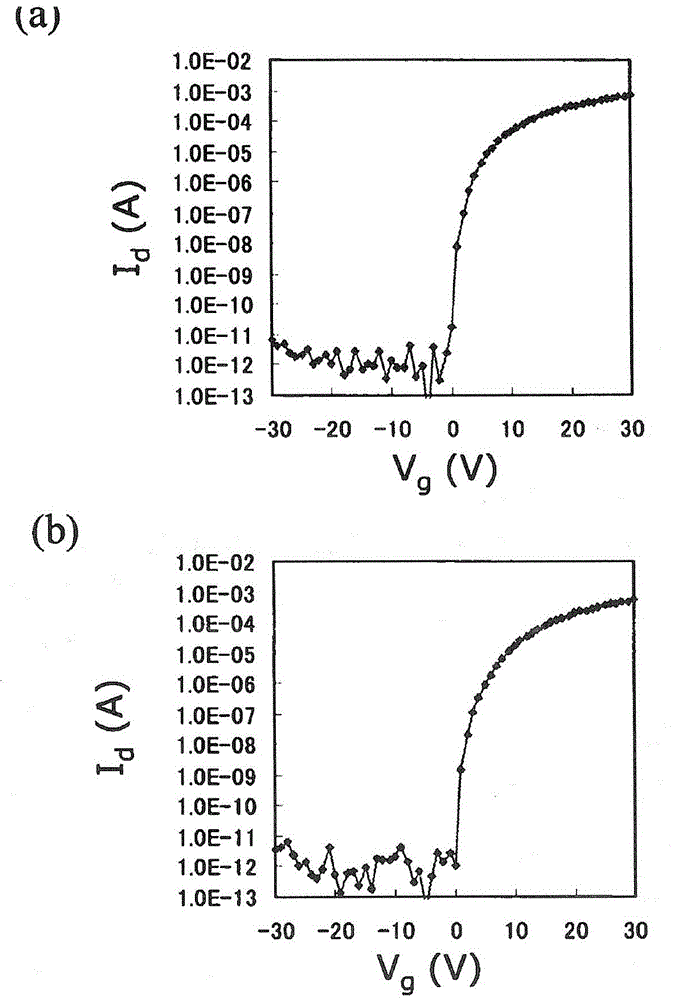

[0126] In this example, each TFT produced in the same manner as in Example 1 using various oxide thin films described in Table 1 and Table 2 was evaluated in the following manner (4) Stress tolerance before and after stress application.

[0127] (4) Evaluation of stress tolerance (light irradiation + negative bias applied as stress)

[0128] In the present example, a stress application test in which light is irradiated while applying a negative bias to the gate electrode is performed by simulating the environment (stress) at the time of actual panel driving. Stress application conditions are as follows. As the wavelength of light, select about 400 nm, which is close to the bandgap of the oxide semiconductor, and the transistor characteristics are likely to fluctuate.

[0129] Gate voltage: -20V

[0130] Drain voltage: 10V

[0131] Substrate temperature: 60°C

[0132] light stress

[0133] Wavelength: 400nm

[0134] Illuminance (intensity of light irradiated to TFT): 80nW...

Embodiment 3

[0160] In this embodiment, the oxide corresponding to No.3 composition of Table 3 (ZnSnO+3at%Al, [Zn]:[Sn]=6:4, Zn ratio=[Zn] / [Zn]+[ Sn]=0.6, Al ratio=[Al] / [Zn]+[Sn]+[Al]=0.03), the oxide film ( The film thickness was 100 nm), and the mobility and the threshold voltage change (ΔVth) after the stress test (external light irradiation + negative bias) were investigated for the TFT fabricated in the same manner as in Example 2 above. The method of measuring the film density is as follows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com