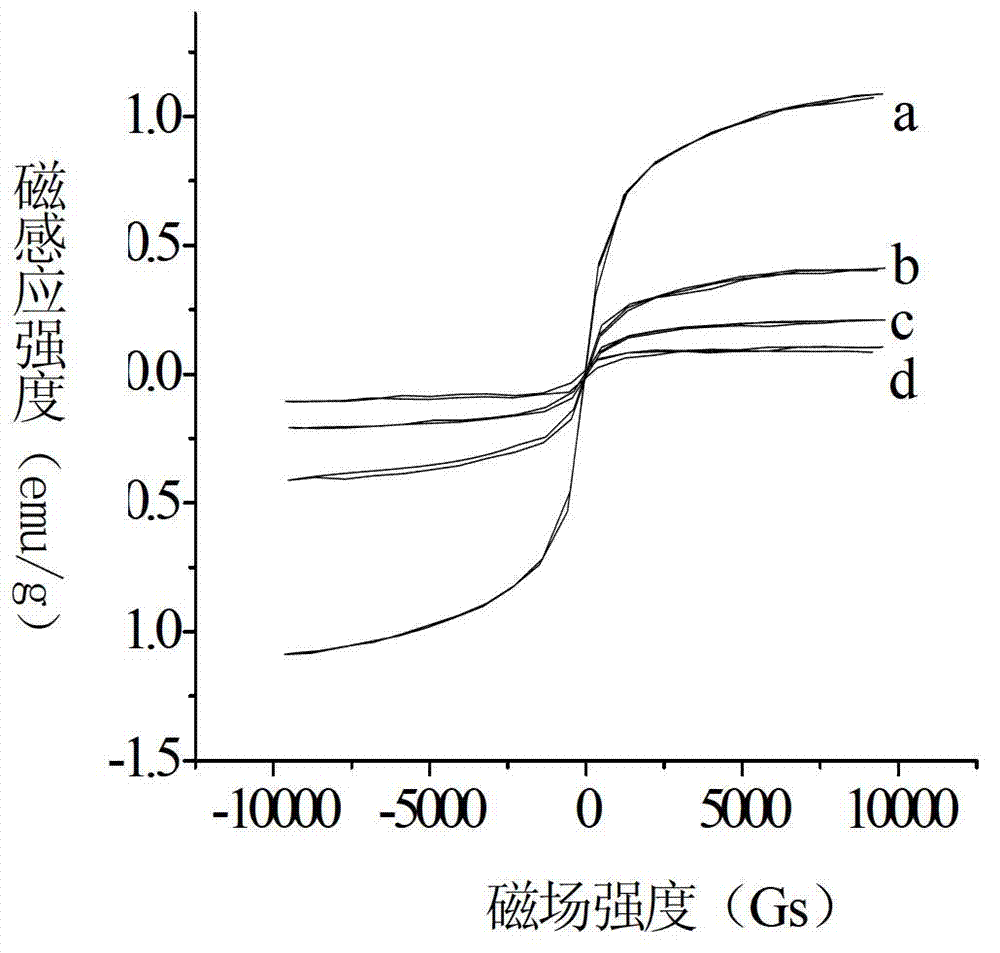

Preparation method of surface-modified fluorescent magnetic polymer composite microspheres

A technology of composite microspheres and surface modification, which is applied across the three major fields of chemistry, physics and biology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

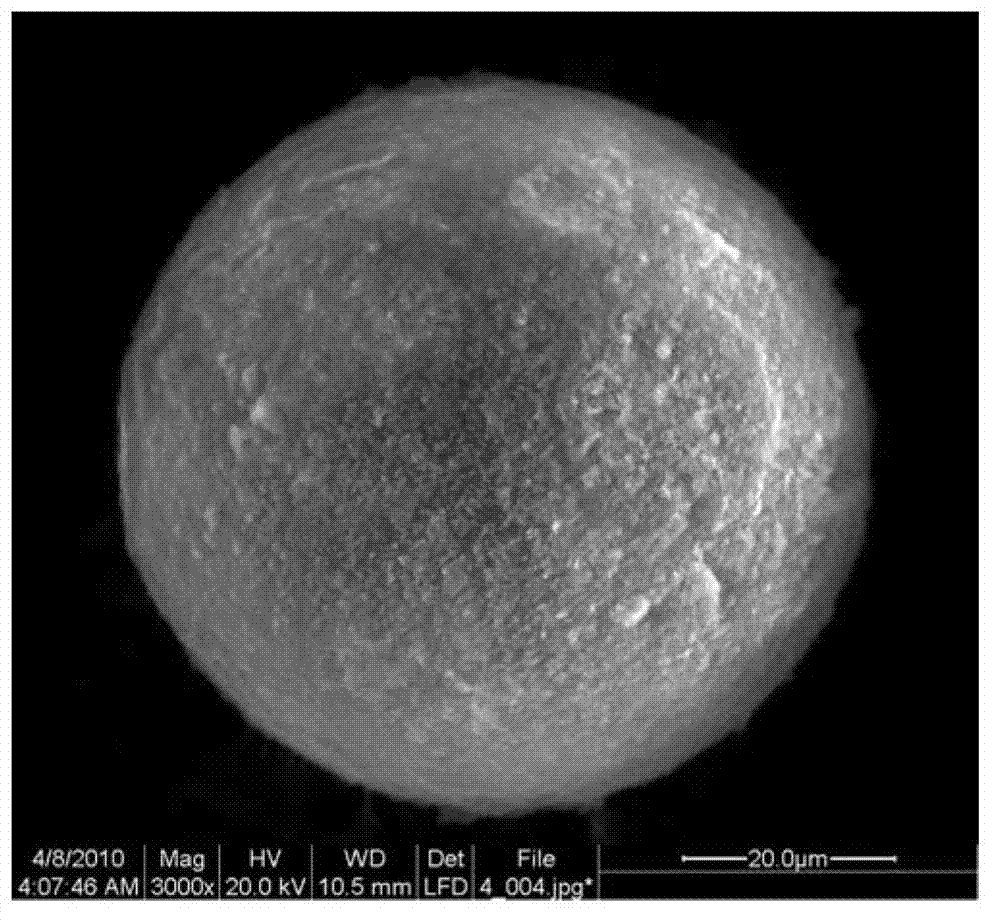

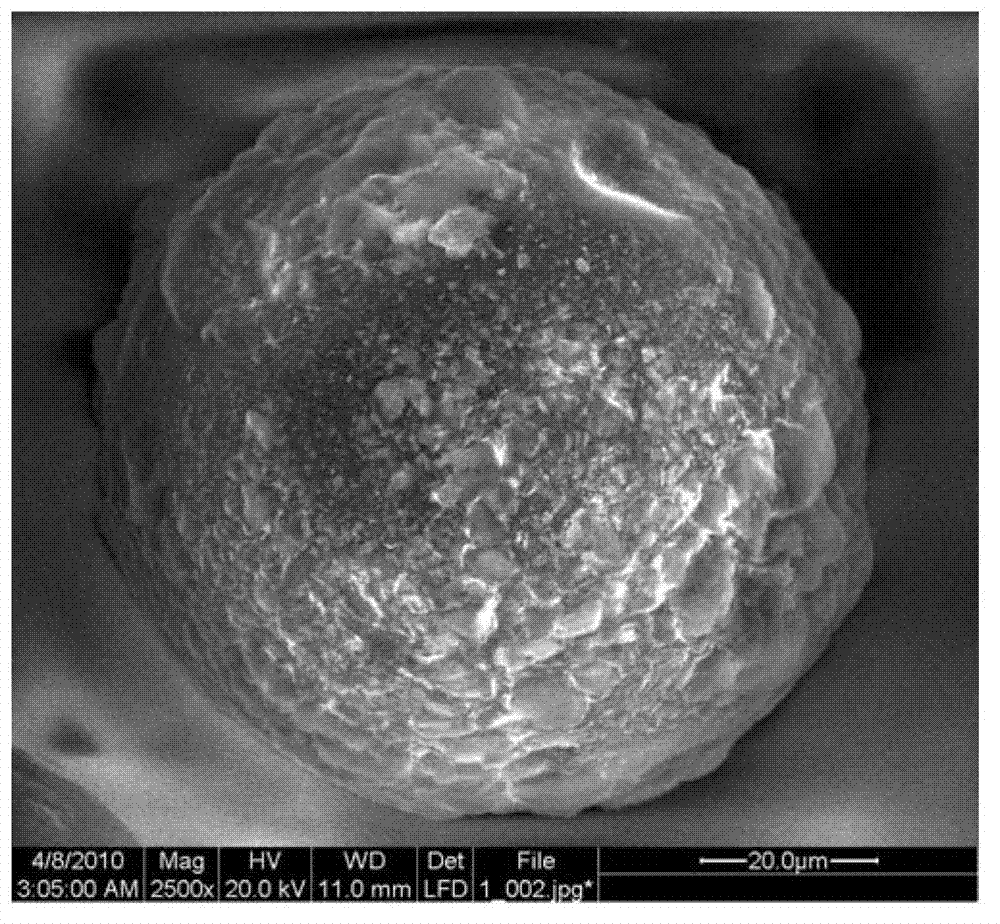

Embodiment 1

[0047] The steps of the preparation method of the surface-modified fluorescent magnetic polymer composite microspheres in this example are as follows:

[0048] 1. Preparation of dextran-modified nanoscale Fe 3 o 4 Dispersions

[0049] 20°C, add 150mL twice distilled water into the three-necked flask, stir and add 2.93g FeCl in turn under the protection of N2 3 ·6H 2 O was formulated into FeCl with a mass concentration of 19.55% 3 ·6H 2 O aqueous solution, 1.45g FeCl 2 4H 2 O was formulated into FeCl with a mass concentration of 14.46% 2 4H 2 O aqueous solution, 1g number-average molecular weight is that the dextran of 40000 is mixed with mass concentration and is that 3.23% number-average molecular weight is the dextran aqueous solution of 40000, stirring fully mixes, and adding 2.20g NaOH is mixed with the NaOH aqueous solution that mass concentration is 3.92%, Dextran and FeCl 3 ·6H 2 O, FeCl 24H 2 The mass ratio of O, NaOH, and double-distilled water is 1:2.93:...

Embodiment 2

[0065] The steps of the preparation method of the surface-modified fluorescent magnetic polymer composite microspheres in this example are as follows:

[0066] In the preparation of dextran-modified nanoscale Fe 3 o 4 In step 1 of the dispersion solution, add 150 mL of twice distilled water into a three-necked flask at 20°C, and stir under N 2 Under protection, add 2.93g FeCl successively 3 ·6H 2 O was formulated into FeCl with a mass concentration of 19.55% 3 ·6H 2 O aqueous solution, 1.45g FeCl 2 4H 2 O was formulated into FeCl with a mass concentration of 14.46% 2 4H 2 O aqueous solution, 1g number-average molecular weight is that the dextran of 40000 is mixed with mass concentration and is that 3.23% number-average molecular weight is the dextran aqueous solution of 40000, stirring fully mixes, and adding 2.20g NaOH is mixed with the NaOH aqueous solution that mass concentration is 3.92%, Dextran and FeCl 3 ·6H 2 O, FeCl 2 4H 2 The mass ratio of O, NaOH, and d...

Embodiment 3

[0073] The steps of the preparation method of the surface-modified fluorescent magnetic polymer composite microspheres in this example are as follows:

[0074] In the preparation of dextran-modified nanoscale Fe 3 o 4 In step 1 of the dispersion solution, add 150 mL of twice distilled water into a three-necked flask at 20°C, and stir under N 2 Under protection, add 2.93g FeCl successively 3 ·6H 2 O was formulated into FeCl with a mass concentration of 19.55% 3 ·6H 2 O aqueous solution, 1.45g FeCl 2 4H 2 O was formulated into FeCl with a mass concentration of 14.46% 2 4H 2 O aqueous solution, 1g number-average molecular weight is that the dextran of 40000 is mixed with mass concentration and is that 3.23% number-average molecular weight is the dextran aqueous solution of 40000, stirring fully mixes, and adding 2.20g NaOH is mixed with the NaOH aqueous solution that mass concentration is 3.92% , dextran and FeCl 3 ·6H 2 O, FeCl 2 4H 2 The mass ratio of O, NaOH, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com