Preparation method of modified nano silicon dioxide

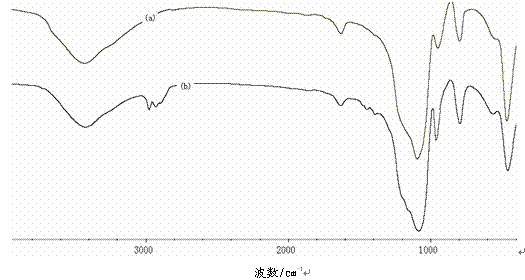

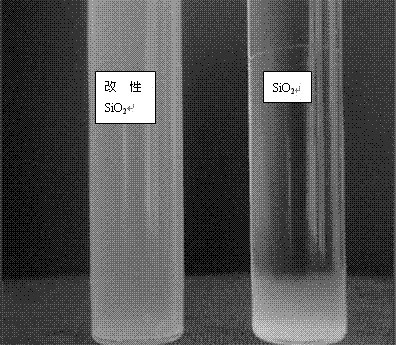

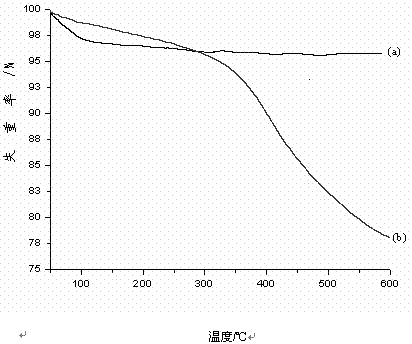

A nano-silica, modification technology, applied in the treatment of dyed organosilicon compounds, fibrous fillers, etc., can solve the problems of large amount of modifiers, long reaction time, poor dispersion of organic compounds, etc., and reach the particle size distribution range Small size, high production efficiency, and the effect of preventing secondary agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Add 4g of deionized water to 230g of ethanol, and oscillate ultrasonically for 10 minutes;

[0023] (2) Under ultrasonic vibration, add 10.4g tetraethyl orthosilicate (TEOS) into the above solution, and shake for 30 minutes;

[0024] (3) Use 0.1mol / L hydrochloric acid to adjust the pH value of the solution obtained in step (2) to 4, add 0.52g of silane coupling agent KH560 dropwise to the solution at a rate of 0.5g / min, and put the resulting system in Stir the reaction at a reaction temperature of 60°C for 6 hours;

[0025] (4) Adjust the pH value of the solution obtained in step (3) to 9 with 0.05mol / L ammonia water, and keep it warm for 2 hours;

[0026] (5) The modified nano-silica sol obtained in step (4) was dried, pulverized, sieved, washed with absolute ethanol for 5 times, washed with water, vacuum-dried at 80°C for 24 hours, and ground to obtain in-situ modified nano-silica sol. silica.

Embodiment 2

[0028] (1) Add 5g of deionized water to 230g of ethanol, and oscillate ultrasonically for 15 minutes;

[0029] (2) Under ultrasonic vibration, add 10.4g tetraethyl orthosilicate (TEOS) into the above solution, and shake for 30 minutes;

[0030] (3) Use 0.1mol / L hydrochloric acid to adjust the pH value of the solution obtained in step (2) to 3, add 1.04g of silane coupling agent KH560 to the solution dropwise at a rate of 0.5g / min, and put the resulting system in Stir the reaction at a reaction temperature of 60°C for 6 hours;

[0031] (4) Adjust the pH value of the solution obtained in step (3) to 9 with 0.05mol / L ammonia water, and keep it warm for 2 hours;

[0032] (5) The modified nano-silica sol obtained in step (4) was dried, pulverized, sieved, washed with absolute ethanol for 5 times, washed with water, vacuum-dried at 80°C for 24 hours, and ground to obtain in-situ modified nano-silica sol. silica.

Embodiment 3

[0034] (1) Add 7g of deionized water to 230g of ethanol, and ultrasonically shake for 10min;

[0035] (2) Under ultrasonic vibration, add 10.4g tetraethyl orthosilicate (TEOS) into the above solution, and shake for 30 minutes;

[0036] (3) Use 0.1mol / L hydrochloric acid to adjust the pH value of the solution obtained in step (2) to 5, add 1.56g of silane coupling agent KH560 dropwise to the solution at a rate of 0.5g / min, and put the resulting system in Stir the reaction at a reaction temperature of 60°C for 6 hours;

[0037] (4) Adjust the pH value of the solution obtained in step (3) to 9 with 0.05mol / L ammonia water, and keep it warm for 2 hours;

[0038] (5) The modified nano-silica sol obtained in step (4) was dried, pulverized, sieved, washed with absolute ethanol for 5 times, washed with water, vacuum-dried at 80°C for 24 hours, and ground to obtain in-situ modified nano-silica sol. silica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com