POE (ethylene-octene copolymer) spectrum conversion solar cell packaging rubber film and preparation method thereof

A solar cell and spectrum conversion technology, applied in photovoltaic power generation, circuits, adhesives, etc., can solve the problems of poor UV resistance and damp heat aging performance, reduced solar cell conversion efficiency, and reduced light transmittance of packaging films. Uniform, low cost, easy to generate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

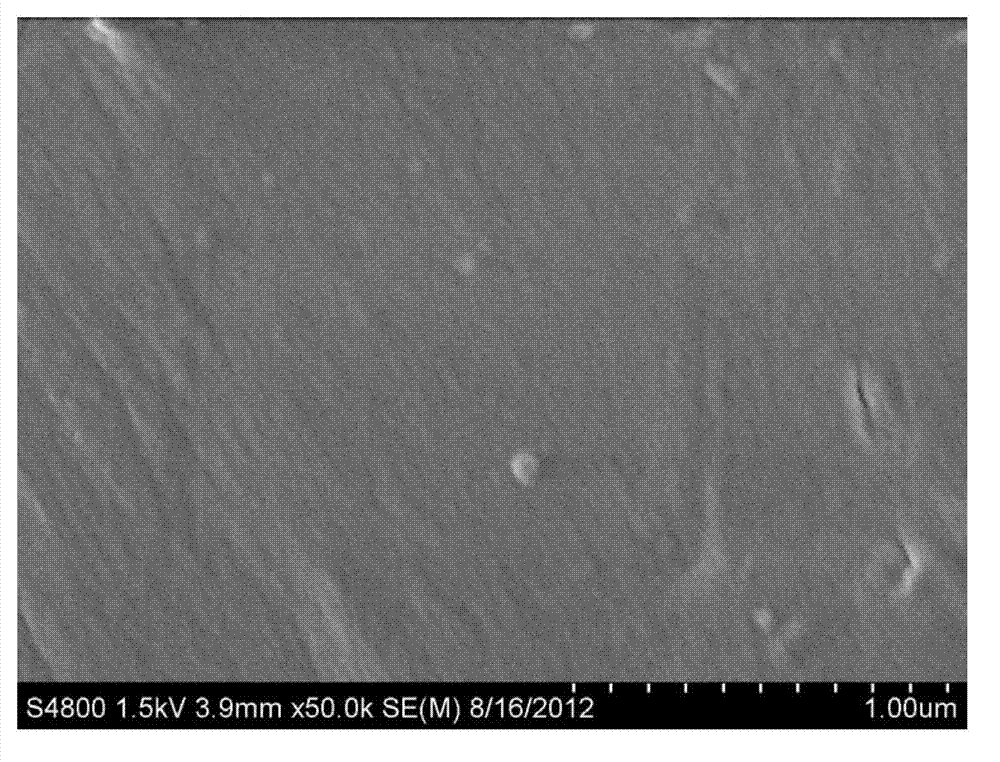

Image

Examples

Embodiment 1

[0070] (1) 70 parts of POE with melting index of 5g / min and 85% light transmittance, 30 parts of NaYF 4 :Er 3+ Put it into an extruder, mix and extrude at 120°C and granulate to obtain spectrum conversion granules a.

[0071] (2) 30 parts of POE with melting index of 5g / min and 85% light transmittance, 70 parts of NaYF 4 :Eu 3+ Put it into an extruder, mix and extrude at 120°C and granulate to obtain spectral conversion granules b.

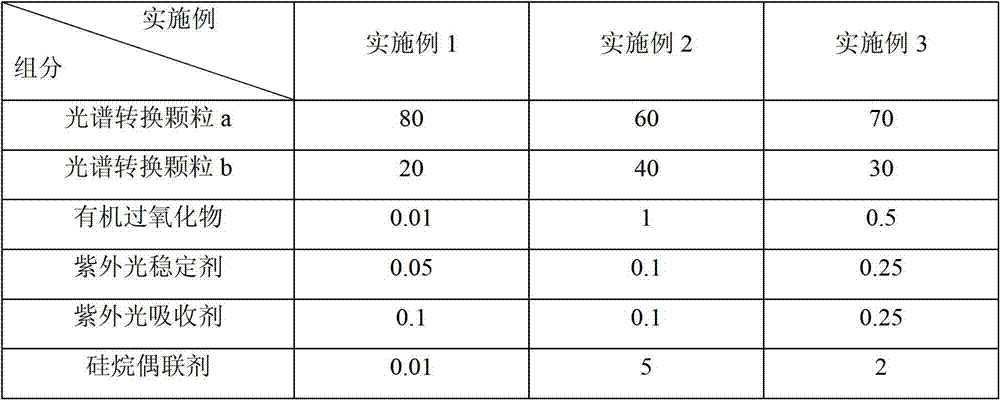

[0072] (3) Mix 80 parts of spectrum conversion particles a, 20 parts of spectrum conversion particles b, 0.01 parts of organic peroxide dicumyl peroxide, 0.05 parts of UV light stabilizer poly[1-(2′-hydroxyethyl)- 2,2,6,6-Tetramethyl-4-hydroxypiperidine succinate], 0.1 part of UV absorber 2-hydroxy-4-n-octyloxybenzophenone, 0.01 part of silane coupling agent Add Z-6030 into the extruder, mix and extrude at 120°C, cast and cool to form, and finally draw and wind the formed film.

Embodiment 2

[0074] (1) 95 parts of POE with melting index of 30g / min and 95% light transmittance, 5 parts of NaYF 4 :Yb 3+ ,Er 3+ Put it into an extruder, mix and extrude at 100°C and granulate to obtain spectrum conversion granules a.

[0075] (2) 5 parts of POE with melting index of 30g / min and 95% light transmittance, 95 parts of NaYF 4 :Yb 3+ ,Pr 3+ Put it into an extruder, mix and extrude at 100°C and granulate to obtain spectral conversion granules b.

[0076] (3) 60 parts of spectral conversion particles a, 40 parts of spectral conversion particles b, 1 part of organic peroxide tert-butylperoxycarbonate-2-ethylhexyl, 0.1 parts of UV light stabilizer sebacic acid bis-2, 2,6,6-Tetramethylpiperidinol ester, 0.1 part UV absorber 2-(2H-benzotriazol-2-yl)-6-(dodecyl)-4-methylphenol, Add 5 parts of silane coupling agent KH-550 into the extruder, mix and extrude at 100°C, and cast to form a film.

Embodiment 3

[0078] (1) 80 parts of POE with melting index of 15g / min and 90% light transmittance, 20 parts of LiYF 4 :Er 3+ Put it into an extruder, mix and extrude at 110°C and granulate to obtain spectrum conversion granules a.

[0079] (2) 20 parts of POE with melting index of 15g / min and 90% light transmittance, 80 parts of GdAl 3 (BO 3 ) 4 :Yb 3+ ,Tb 3+ Put it into an extruder, mix and extrude at 110°C and granulate to obtain spectrum conversion granules b.

[0080] (3) 70 parts of spectral conversion particles a, 30 parts of spectral conversion particles b, 0.5 parts of organic peroxide 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane, 0.25 parts UV stabilizer bis-2,2,6,6-tetramethylpiperidinol sebacate, 0.25 parts of UV absorber 2-(2H-benzotriazol-2-yl)-6-(dodecyl Alkyl)-4-methylphenol and 2 parts of silane coupling agent KH-550 are added to the extruder, mixed and extruded at 110°C, cast and cooled to form, and finally the formed film is drawn and wound.

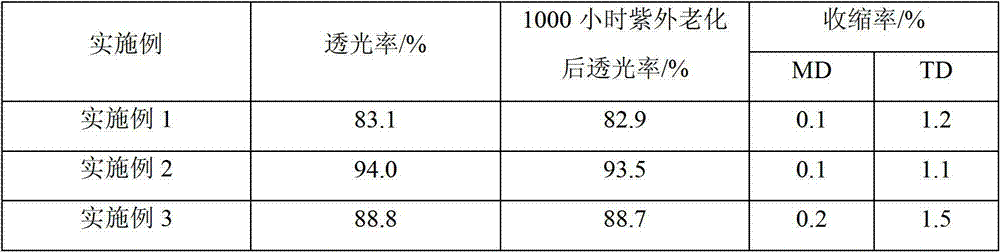

[0081] The component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com