Waterborne polyurethane shoe adhesive and preparation method thereof

A water-based polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of low bonding strength, poor water resistance, low solid content of water-based polyurethane, etc., and achieve high adhesion. The effect of excellent water resistance, excellent water resistance and excellent solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

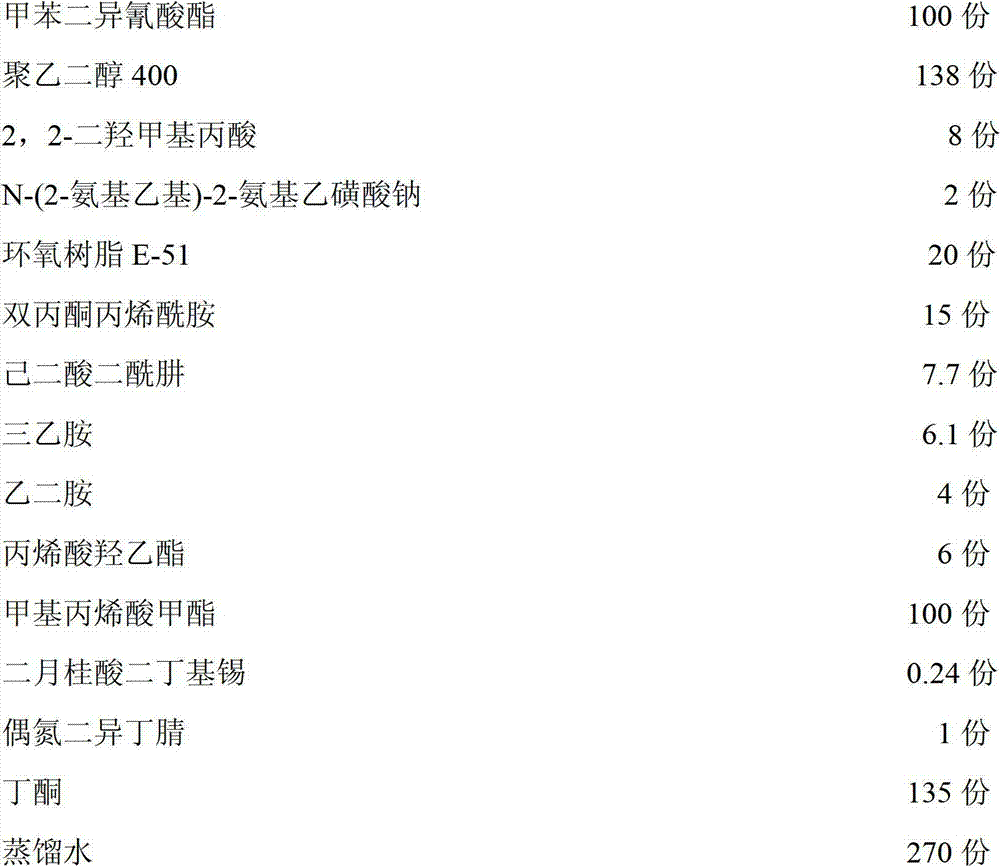

Embodiment 1

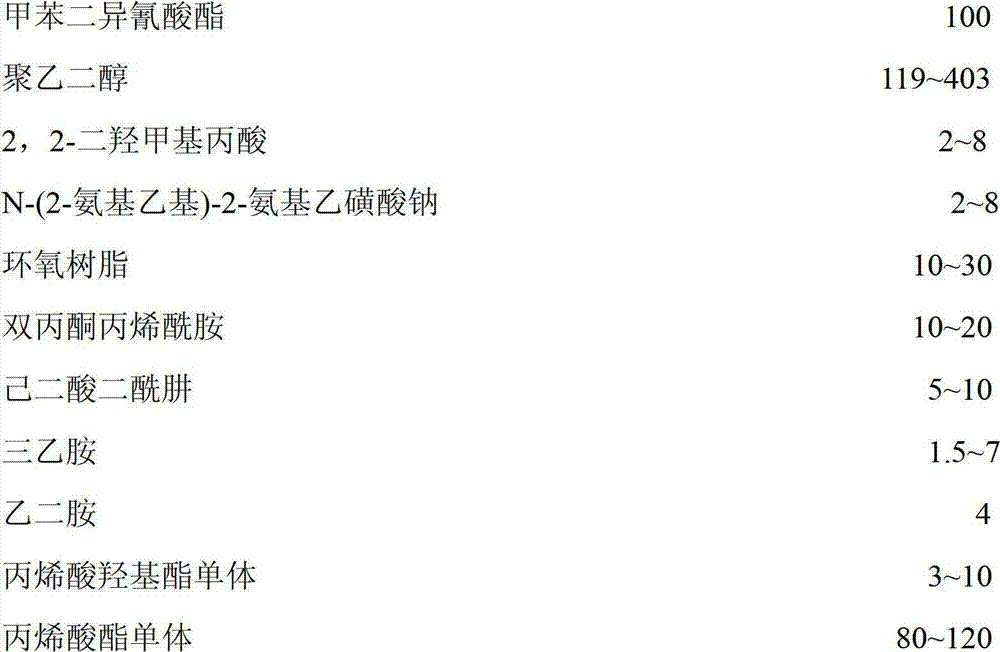

[0034] The water-based polyurethane shoe adhesive is mainly made of the following raw material components in mass ratio:

[0035]

[0036] 1) Add methyl ethyl ketone, dehydrated polyethylene glycol 600, 2,2-dimethylolpropionic acid and toluene diisocyanate into a container equipped with a stirring rod and a reflux condenser, stir evenly, and stabilize the temperature to room temperature Then add dibutyltin dilaurate, raise the temperature to 70°C, and react for 2 hours to obtain polyurethane solution A.

[0037] 2) Add epoxy resin E-51 to polyurethane solution A, keep the temperature at 70°C, and react for 1 hour to obtain polyurethane solution B.

[0038] 3) Add hydroxyethyl acrylate to polyurethane solution B, keep the temperature at 70°C, react for 1 hour, cool down to 30°C, add methyl methacrylate and diacetone acrylamide, stir for 15 minutes, add triethylamine, and continue stirring 15min to obtain polyurethane solution C.

[0039] 4) Add N-(2-aminoethyl)-2-aminoetha...

Embodiment 2

[0047] Similar to Example 1, the difference is that polyethylene glycol 400 is changed to polyethylene glycol 600, and the specific formula is shown in formula 2 in Table 1.

Embodiment 3

[0049] Similar to Example 1, the difference is that polyethylene glycol 400 is changed to polyethylene glycol 1000, and the specific formula is shown in formula 3 in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| storage stability | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com