Preparation method of fiber-reinforced titanium matrix composite precursors

A titanium-based composite material and fiber-reinforced technology, which is applied in metal material coating technology, ion implantation plating, coating, etc., can solve problems that have not yet been discovered, and achieve the goals of avoiding interface pollution, good bonding, and good interface performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the fiber-reinforced titanium matrix composite material precursor of the present embodiment comprises the following steps:

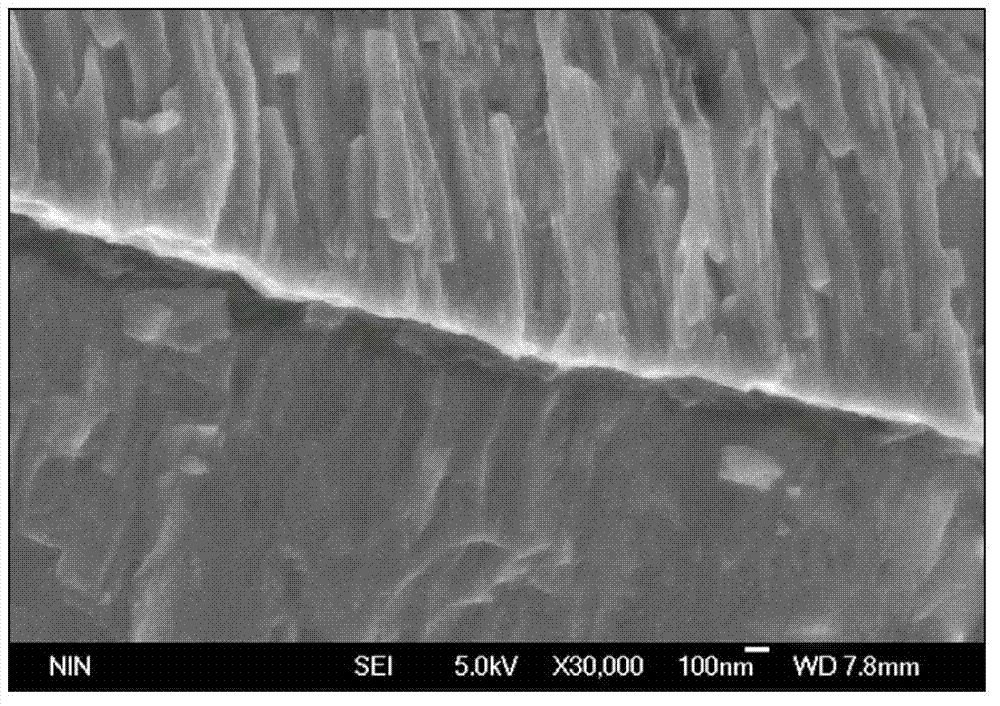

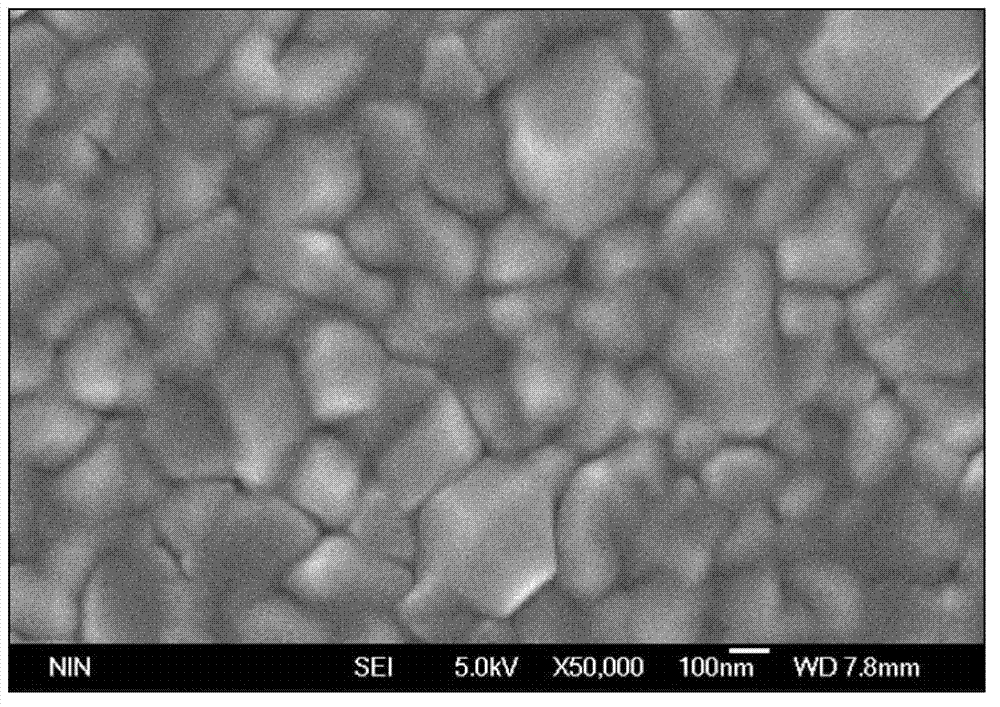

[0034] Step 1. Preparation of SiC_f / La 2 Zr 2 o 7 Silk:

[0035] Step 101. Put lanthanum zirconate with pyrochlore structure, TC4 titanium alloy and silicon carbide fiber together into a multi-target magnetron sputtering apparatus (JGP600 ultra-high vacuum multi-target magnetron sputtering apparatus, developed by Shenyang Scientific Instruments, Chinese Academy of Sciences Center Co., Ltd.) in the sputtering chamber, lanthanum zirconate is used as the sputtering target and silicon carbide fiber is used as the base material;

[0036] Step 102, vacuumize the sputtering chamber to a vacuum degree of 3×10 -5 Pa, and the silicon carbide fiber is heated to 500 ° C, and then argon gas is introduced into the sputtering chamber, and the radio frequency magnetron sputtering treatment is carried out under the conditions of argon...

Embodiment 2

[0042] The preparation method of the fiber-reinforced titanium matrix composite material precursor of the present embodiment comprises the following steps:

[0043] Step 1. Preparation of SiC_f / La 2 Zr 2 o 7 Silk:

[0044] Step 101. Put lanthanum zirconate with pyrochlore structure, TB8 titanium alloy and silicon carbide fiber together into a multi-target magnetron sputtering apparatus (JGP600 ultra-high vacuum multi-target magnetron sputtering apparatus, developed by Shenyang Scientific Instruments, Chinese Academy of Sciences Center Co., Ltd.) in the sputtering chamber, lanthanum zirconate is used as the sputtering target and silicon carbide fiber is used as the base material;

[0045] Step 102, vacuumize the sputtering chamber to a vacuum degree of 4×10 -5 Pa, and the silicon carbide fiber is heated to 510 ° C, and then argon gas is introduced into the sputtering chamber, and radio frequency magnetron sputtering is carried out under the conditions of argon gas pressure ...

Embodiment 3

[0051] The preparation method of the fiber-reinforced titanium matrix composite material precursor of the present embodiment comprises the following steps:

[0052] Step 1. Preparation of SiC_f / La 2 Zr 2 o 7 Silk:

[0053] Step 101, put lanthanum zirconate with pyrochlore structure, Ti600 titanium alloy and silicon carbide fiber together into a multi-target magnetron sputtering apparatus (JGP600 ultra-high vacuum multi-target magnetron sputtering apparatus, developed by Shenyang Scientific Instruments, Chinese Academy of Sciences Center Co., Ltd.) in the sputtering chamber, lanthanum zirconate is used as the sputtering target and silicon carbide fiber is used as the base material;

[0054] Step 102, vacuumize the sputtering chamber to a vacuum degree of 2×10 -5 Pa, and the silicon carbide fiber is heated to 490 ° C, and then argon gas is introduced into the sputtering chamber, and the radio frequency magnetron sputtering treatment is carried out under the conditions of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com