Negative electrode active material for secondary battery, preparation method and secondary battery thereof

A negative electrode active material, secondary battery technology, applied in secondary batteries, battery electrodes, nanotechnology for materials and surface science, etc., can solve lithium-ion battery performance to be improved, low cycle stability and specific capacity, Unable to form three-dimensional multi-level structure and other problems, to achieve the effects of stable performance, improved electrical conductivity, and reduced ohmic polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

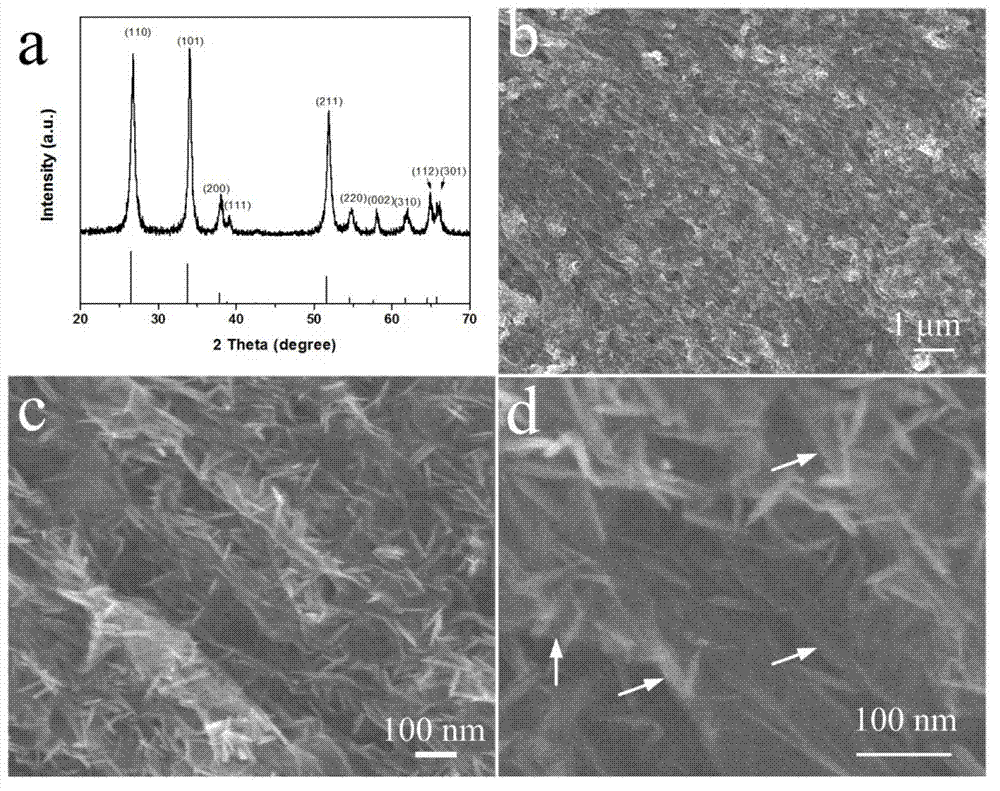

[0041] Add 5 parts of self-made graphene oxide to a mixture containing 200 parts of urea (1 g per 100 parts), 35 parts of SnCl 4 ·5H 2 O. In the mixed aqueous solution (8000 parts) of 37 parts of thioglycolic acid and water, ultrasonic for 30 minutes, finally transfer the mixed solution into a polytetrafluoroethylene liner, put it in a steel autoclave, 180°C After 12 hours of reaction, SnO was prepared 2 Nanorod Array / Graphite Nanoflake Composite.

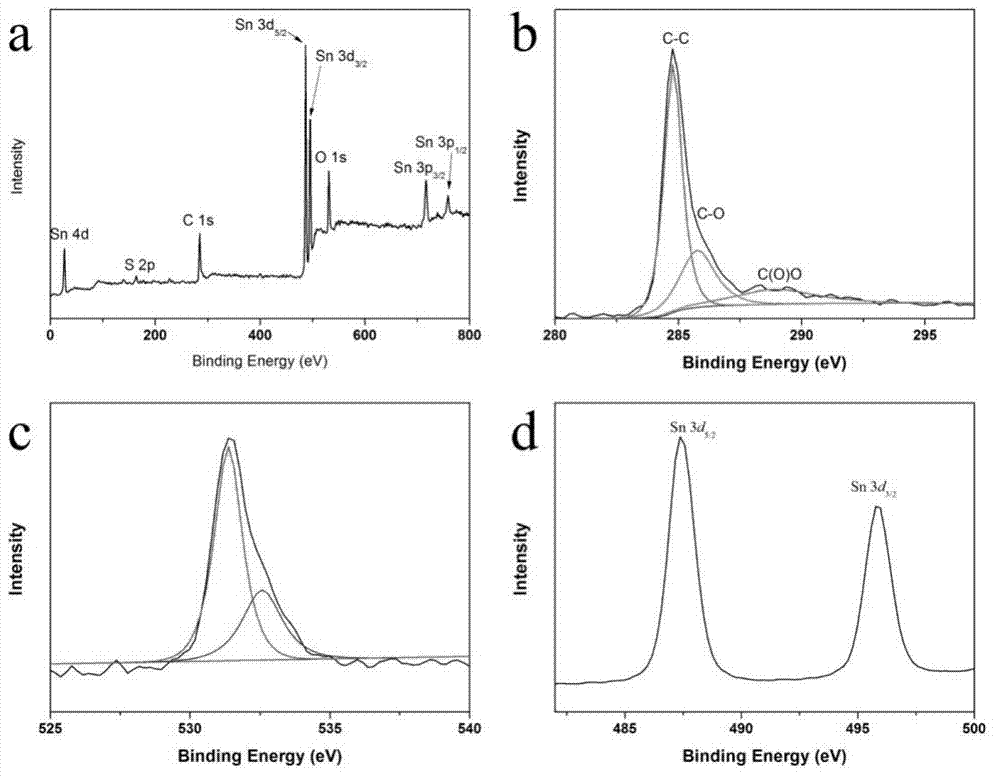

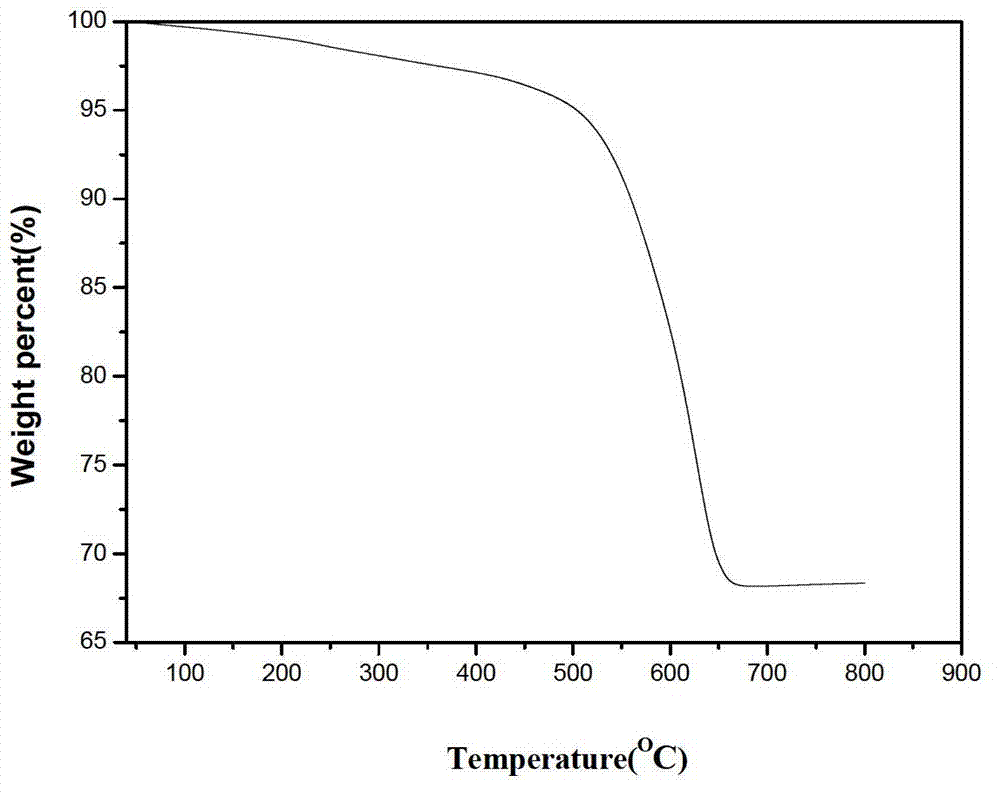

[0042] figure 1 is the XPS energy spectrum of the sample obtained in Example 1. Four elements of Sn, O, C, and S can be found in the full spectrum, and the Sn 3d spectrum is composed of Sn 3d with an electron binding energy of 487.7eV 5 / 2 Characteristic peaks and Sn 3d with electron binding energy of 495.8eV 3 / 2 Composition of characteristic peaks, there is no other Sn element in the spectrum (Sn 3d 5 / 2 , 485.0eV) and divalent Sn (Sn 3d 5 / 2 , 485.8eV) characteristic peak, indicating that the composite is composed of graphene...

Embodiment 2

[0044] Add 5 parts of self-made graphene to 50 parts of urea, 10 parts of SnCl 4 ·5H 2 O and 11 parts of thioglycolic acid in a mixed aqueous solution (8000 parts), ultrasonic for 30 minutes, and finally the mixed solution was transferred to a polytetrafluoroethylene liner, put into a steel autoclave, and reacted at 180 ° C for 12 SnO was produced after hours 2 Nanorod array / graphite nanoflake composite, in which SnO 2 The length of the nano rod is 50-60nm, and the weight percentage of the graphite nano sheet is 67%. The charge-discharge test was carried out at a charge-discharge current density of 200mA / g, and the reversible specific capacity was 400mAh / g after 100 cycles.

Embodiment 3

[0046] Add 5 parts of self-made graphene oxide and 5 parts of graphene to a mixture containing 200 parts of urea, 35 parts of SnCl 4 ·5H 2 O and 37 parts of thioglycolic acid in a mixed aqueous solution (8000 parts), ultrasonic for 100 minutes, and finally the mixed solution was transferred to a polytetrafluoroethylene liner, put into a steel autoclave, and reacted at 180 ° C for 12 SnO was produced after hours 2 Nanorod array / graphite nanoflake composite, in which SnO 2 The length of the nanorod is 70-80nm, and the weight percentage of the graphite nanosheet is 43%. The charge-discharge test was carried out at a charge-discharge current density of 200mA / g, and the reversible specific capacity was 860mAh / g after 100 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com