Sunlight automatic tracking photothermal catalysis-membrane separation reaction system

A photothermal catalysis and automatic tracking technology, applied in chemical instruments and methods, chemical/physical processes, light water/sewage treatment, etc., can solve the problems of mass transfer limitation, unfavorable long-term operation, high energy consumption, etc., and achieve high light energy Utilization rate and mass transfer efficiency, meeting the demand of light energy and heat energy, and maximizing the effect of light energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

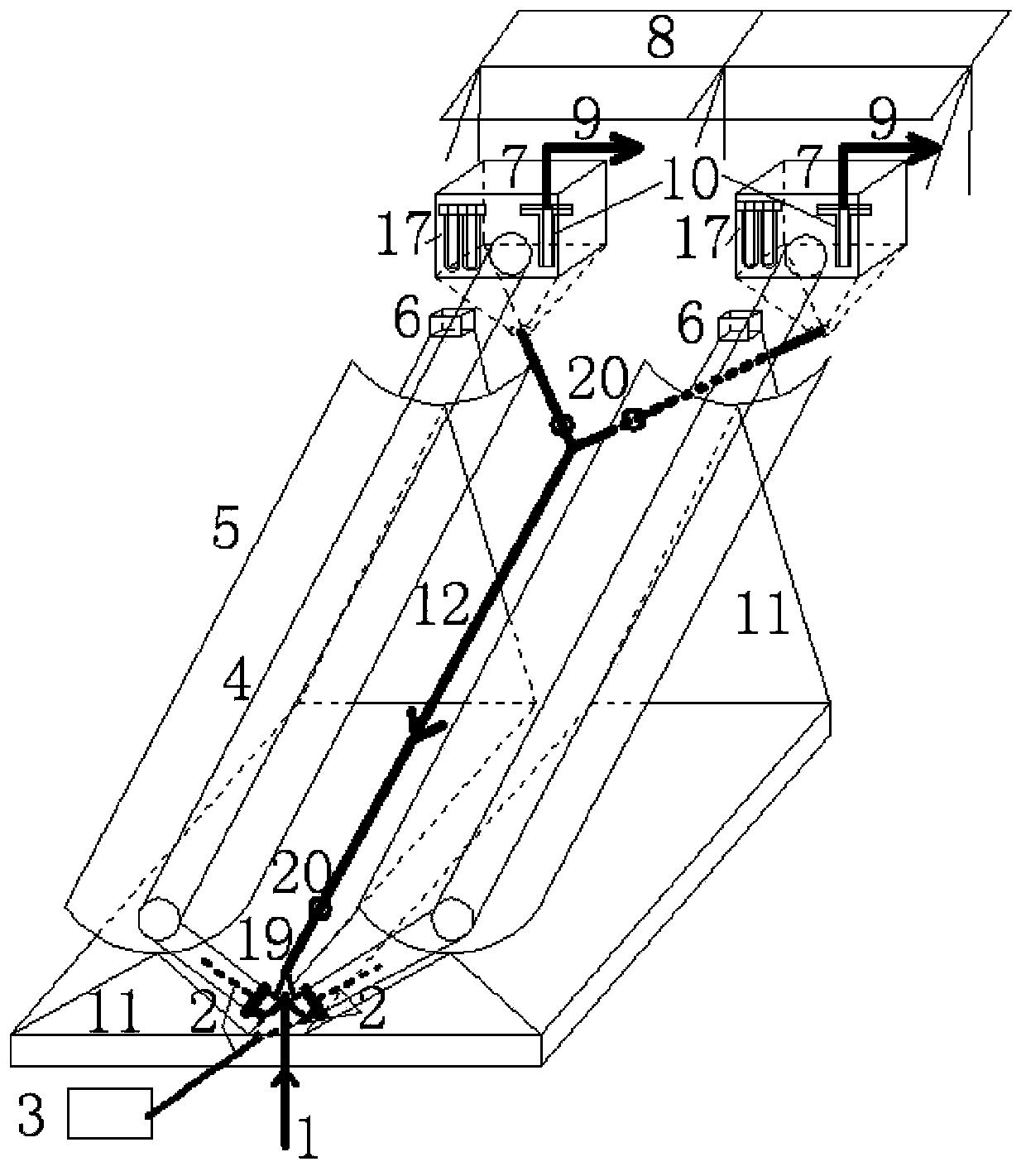

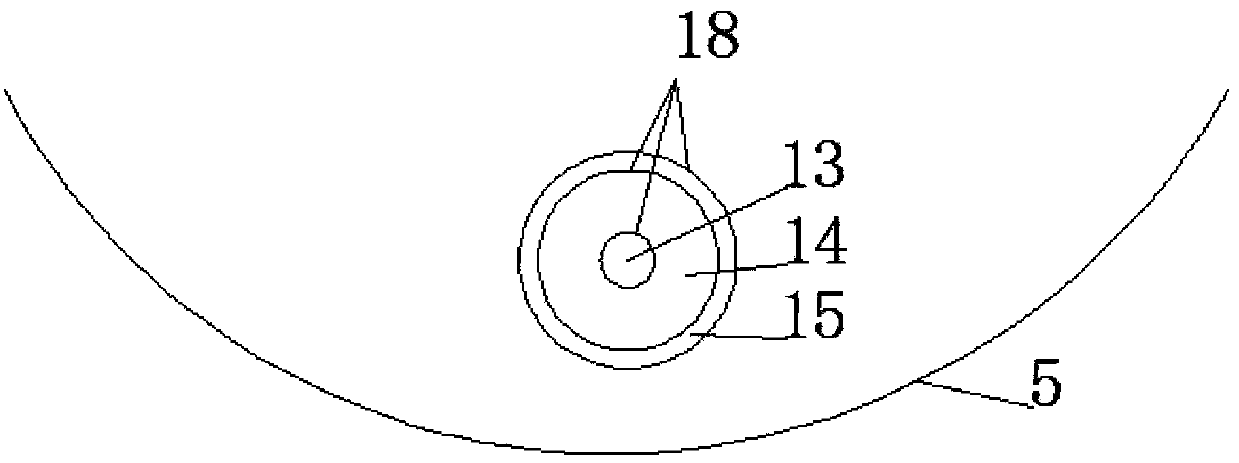

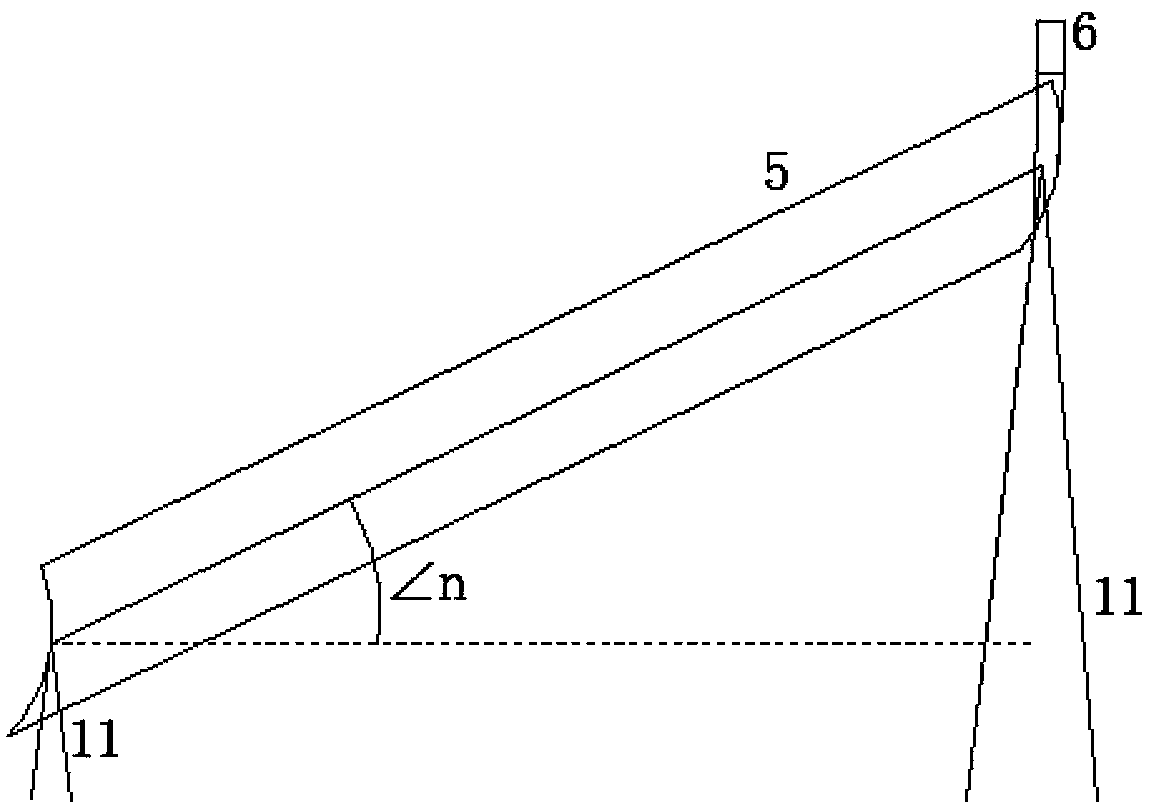

[0028] The photothermal catalysis-membrane separation reaction system with solar automatic tracking function of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] The structure of the sunlight automatic tracking photothermal catalysis-membrane separation reaction system of the present invention is: the system includes a photothermal catalysis reaction zone, a membrane separation zone, a system control zone, and a solar power generation zone; The catalytic reaction tube is connected to the gas-liquid separation water tank in the membrane separation area, and the TiO after being separated by the membrane separation area 2 The catalyst mixture returns to the photothermal catalytic reaction area through the circulation pipe, thus forming a circular reaction system. The system control area controls the working state of the system through the adjustment device of the system control panel, and the solar power generation area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com