Catalyst for preparing distillate oil co-production high alcohol with synthesis gas, preparation method and application

A technology for catalyst and distillate oil is applied in the field of catalyst and preparation for the co-production of high-carbon alcohol from synthesis gas to distillate oil. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

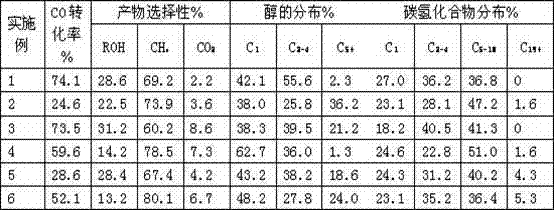

Examples

Embodiment 1

[0034] 3.0g mesoporous carbon (specific surface area is 1985m 2 / g, pore diameter is 3.8nm) is placed in a 500ml two-necked stainless steel flask, one port is directly connected to the water pump, and the other port is connected to a dropping funnel containing 280ml of cobalt nitrate ethanol solution. The concentration of the precursor liquid is 0.05mol / L. The system was vacuumized for 0.5h, and the vacuum degree of the system was 10 -5 Torr, then turn on the switch of the dropping funnel, mix the impregnating solution with the carrier and carry out continuous vacuum treatment, until dry under magnetic stirring. The obtained composite was calcined in an argon atmosphere in a tube furnace at a heating rate of 0.2°C / min, and the required catalyst was obtained after calcining at 300°C for 4 h, in which the loading of metal cobalt was 20wt.%.

[0035] The catalytic reaction is carried out in a fixed-bed reactor. Measure 2ml of the above-mentioned catalyst and put it into a reacti...

Embodiment 2

[0037] 5.0g of multi-walled carbon nanotubes (with a specific surface area of 309m 2 / g, pore diameter is 30nm) placed in a 500ml two-necked stainless steel flask, one port is directly connected to the water pump, and the other port is connected to a dropping funnel containing 200ml of cobalt acetate dissolved in 2-propanol solution, the concentration of the precursor liquid is 0.025mol / L, vacuumize the system for 0.5h, and the vacuum degree of the system is 10-3 Torr, then turn on the switch of the dropping funnel, continue the continuous vacuum treatment after mixing the impregnation solution and the carrier, and stir until dry. The obtained composite was calcined in a tube furnace under a nitrogen atmosphere at a heating rate of 2 °C / min, and the required catalyst was obtained after calcining at 500 °C for 4 h, in which the loading of metal cobalt was 5 wt.%.

[0038] The catalytic reaction is carried out in a fixed-bed reactor. Measure 2ml of the above-mentioned catalys...

Embodiment 3

[0040] 3.0g of activated carbon (with a specific surface area of 980m 2 / g, pore diameter is 15nm) placed in a 500ml two-necked stainless steel flask, one port is directly connected to the water pump, and the other port is connected to a dropping funnel containing 250ml of precursor solution, the precursor liquid is 2.79g cobalt nitrate and 0.17g nitrous acid Nitroruthenium was dissolved in ethanol solution, and the system was vacuumized for 0.5h, and the vacuum degree of the system was 10 -1 Torr, then turn on the switch of the dropping funnel, mix the impregnating solution and the carrier with continuous vacuum treatment, and dry with magnetic agitation. The obtained composite was calcined under the nitrogen atmosphere of the tube furnace, the heating rate was 2°C / min, and the required catalyst was obtained after calcining at 500°C for 4 hours, wherein the loading of metal cobalt was 15wt.%, and the amount of ruthenium as an auxiliary agent was The load is 0.5%.

[0041]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com