Visible-light response type photocatalyst and preparation method thereof

A photocatalyst, visible light technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of reduced catalytic activity, unstable performance, etc., achieving low synthesis temperature, simple preparation process, short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a method for preparing a visible light-responsive photocatalyst, comprising the following steps:

[0027] (A) fully mixing soluble calcium salt, soluble indium salt, thioacetamide and deionized water to obtain a mixed solution;

[0028] (B) subjecting the mixed solution described in step (A) to a hydrothermal reaction under heating conditions, and after filtering and drying, a powder is obtained;

[0029] (C) Under the condition of isolating oxygen, the powder described in the step (B) is heat-treated, and after heat preservation, a visible light-responsive photocatalyst is obtained.

[0030] In the present invention, soluble calcium salt, soluble indium salt, thioacetamide and deionized water are used as reactants, the soluble calcium salt is preferably calcium nitrate, and the soluble indium salt is preferably indium nitrate. The molar ratio of the soluble calcium salt to the soluble indium salt is preferably 1:2, and the molar rat...

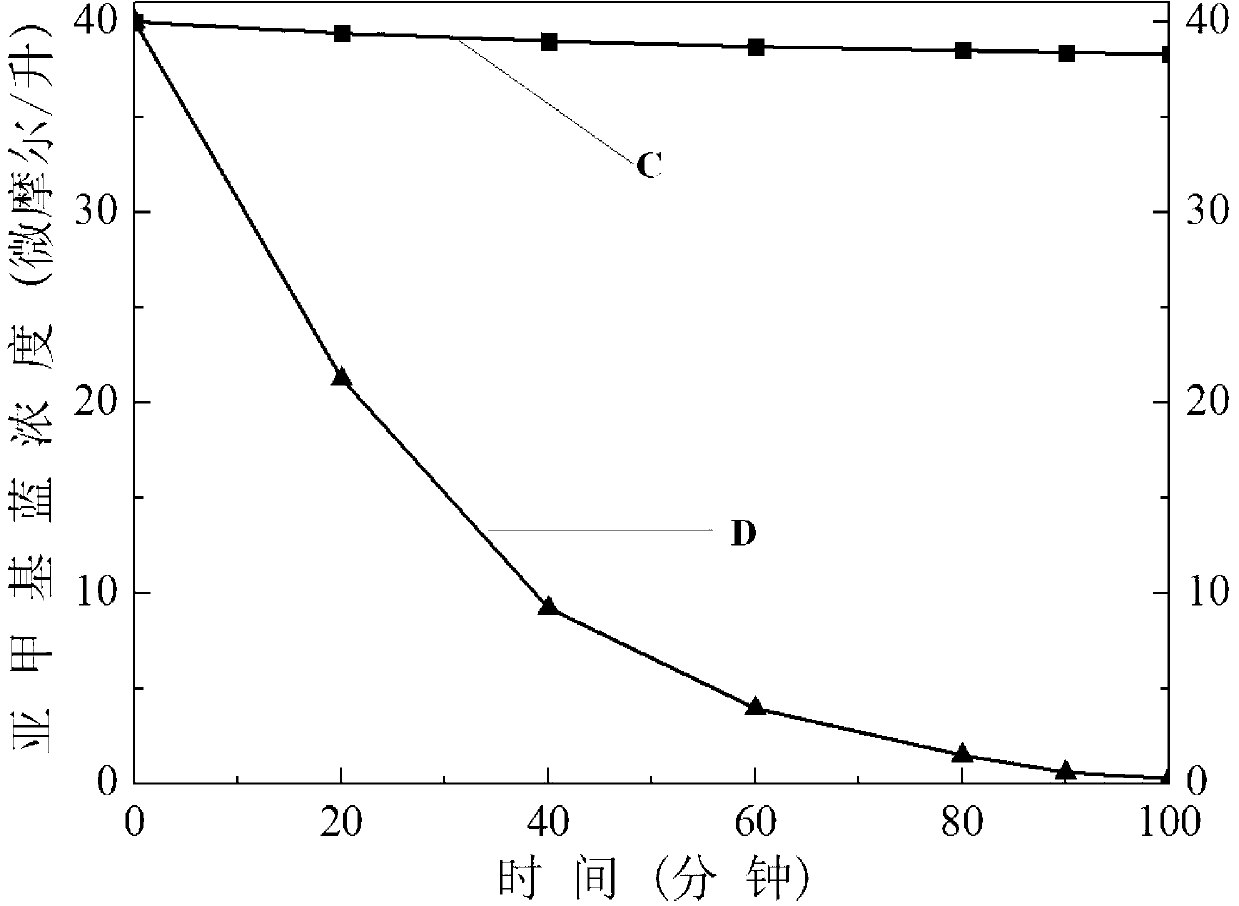

Embodiment 1

[0039] Weigh 2.362 grams of calcium nitrate (Ca(NO 3 ) 2 4H 2 O), 7.638 grams of indium nitrate (In(NO 3 ) 3 9 / 2H 2 O), 6.005 grams of thioacetamide (H 3 CCSNH 2 ), were added to 250 ml beakers respectively, then added deionized water to 150 ml, stirred for 30 minutes, made to mix evenly, and formed a transparent solution;

[0040] The above solution is transferred to the liner of a 200 ml stainless steel reactor, the volume of the solution accounts for 75% of the volume of the reactor, the reactor is sealed, and then the reactor is placed in an oven at 160°C for 16 hours;

[0041] The reacted suspension was taken out, slowly transferred to a Buchner funnel, and deionized water and absolute ethanol (C 2 h 6 O) washing 3 times respectively, and then placing the washed powder in an oven at 120° C. for 12 hours;

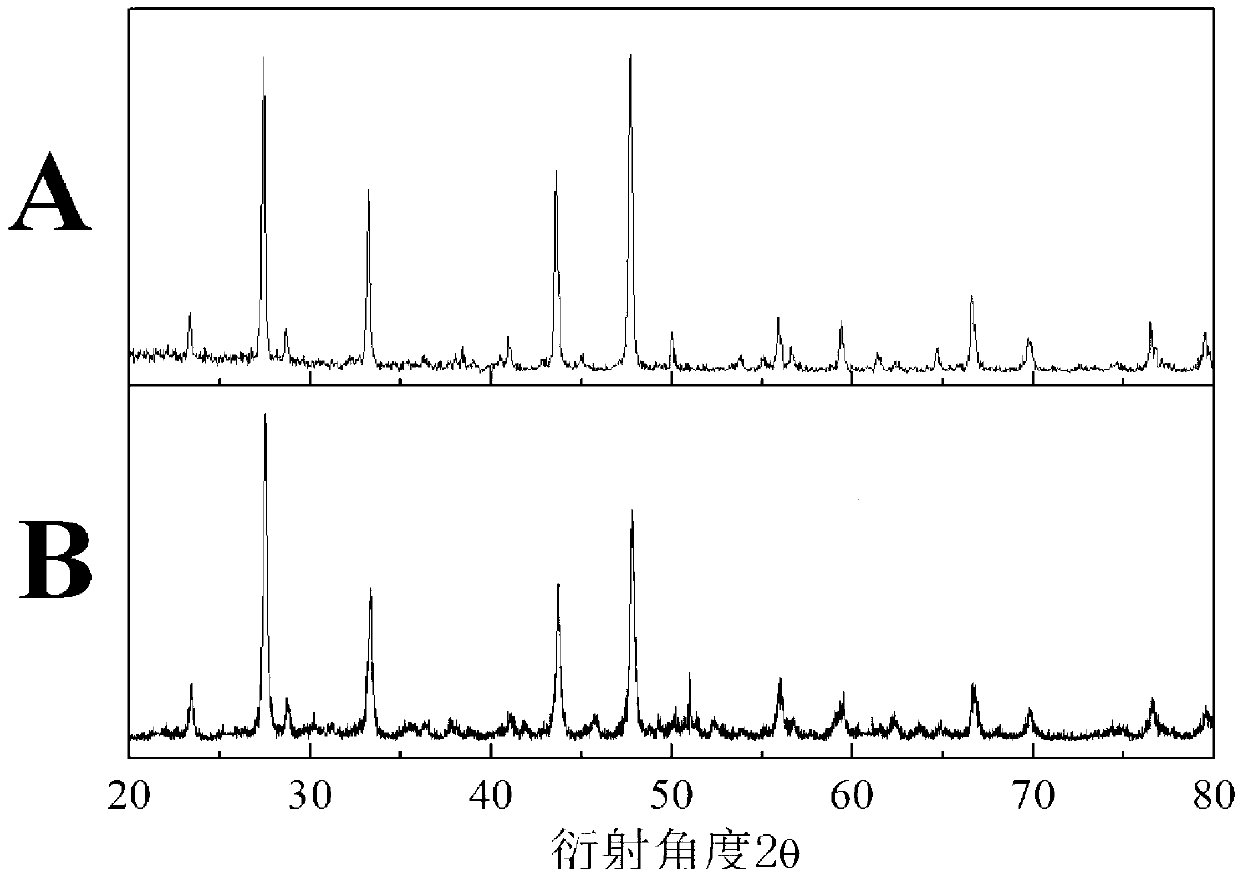

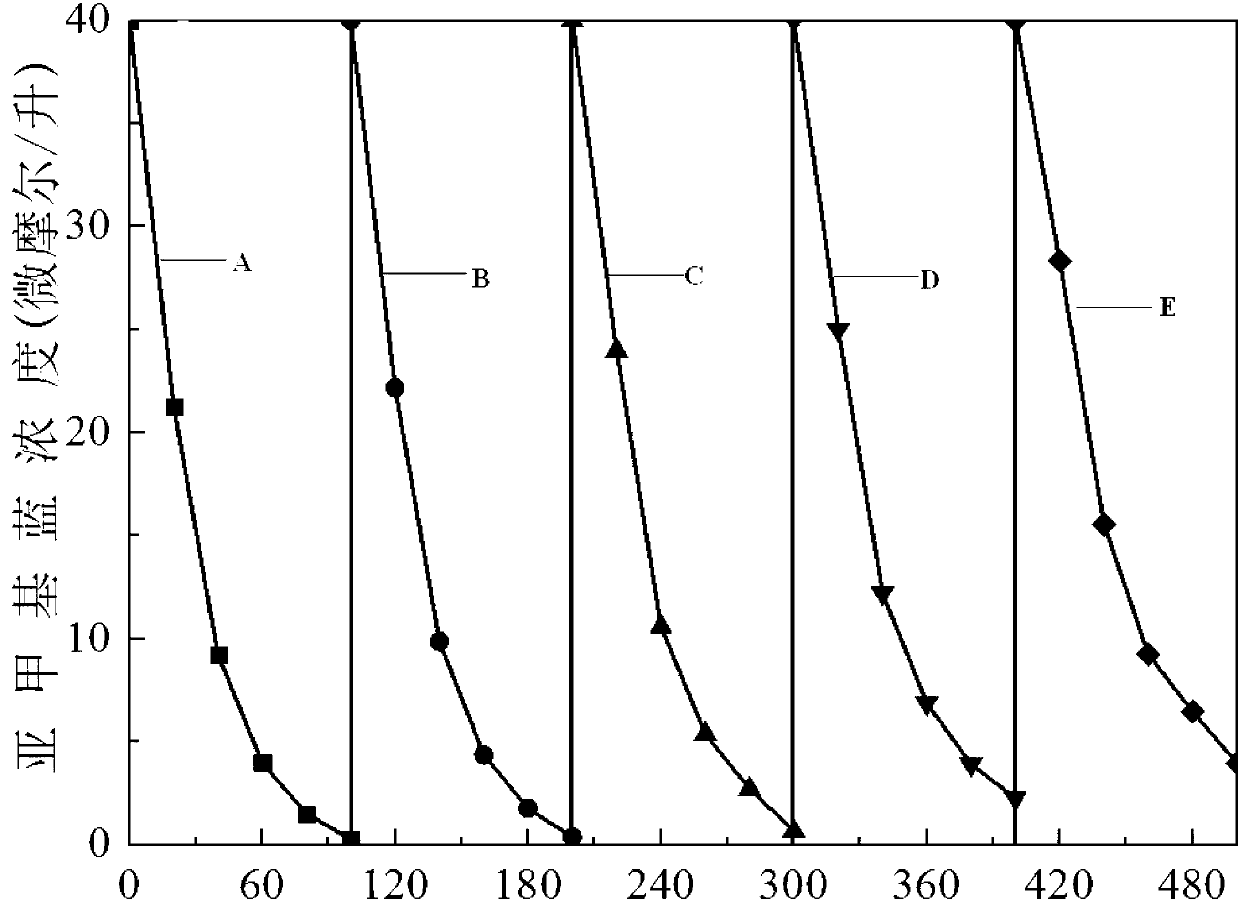

[0042] The above dried powder was placed in a reaction furnace, and in an argon (Ar) atmosphere, the temperature of the reaction furnace was slowly raised to 600...

Embodiment 2

[0048] Weigh 1.181 grams of calcium nitrate (Ca(NO 3 ) 2 4H 2 O), 3.819 grams of indium nitrate (In(NO 3 ) 3 9 / 2H 2 O), 3.002 grams of thioacetamide (H 3 CCSNH 2 ) into a 100 ml beaker, then add deionized water to 80 ml, stir for 60 minutes, make it mix evenly, and form a transparent solution;

[0049] Transfer the above-mentioned homogeneously mixed solution to the liner of a 100 ml stainless steel reactor, the volume of the solution accounts for 80% of the volume of the reactor, seal the reactor, and then place the reactor in an oven at 140°C for 24 hours;

[0050] The reacted suspension was taken out, slowly transferred to a Buchner funnel, and deionized water and absolute ethanol (C 2 h 6 O) washing 4 times respectively, and then placing the washed powder in an oven at 100° C. for 16 hours;

[0051] Put the above-mentioned dried powder in a reaction furnace, raise the temperature of the reaction furnace to 700°C at a rate of 4°C / min in a helium (He) atmosphere, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com