Production method of fire prevention flue and exhaust duct

A production method and air exhaust duct technology, applied in the direction of ceramic forming machines, manufacturing tools, etc., can solve the problems of backward production technology, industrialization restrictions, long production cycle, etc., and achieve strong fireproof and waterproof functions, simple construction, and high mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

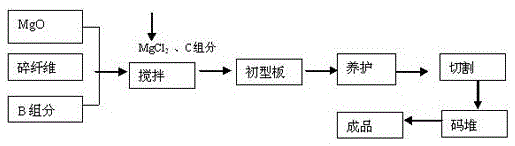

Method used

Image

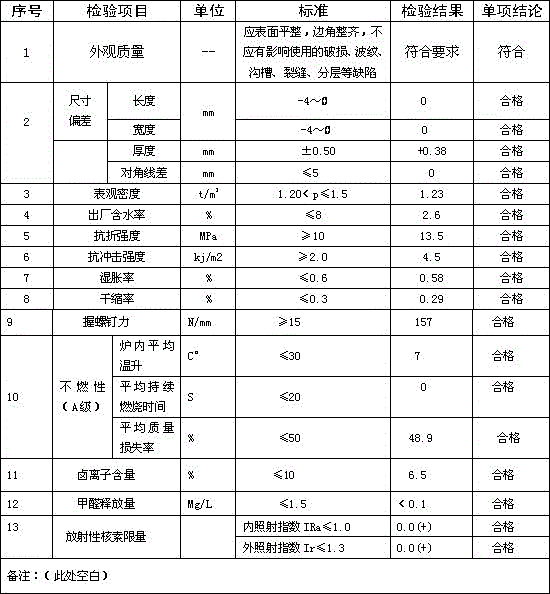

Examples

Embodiment 1

[0041]Get the following raw materials and parts by weight: 30 parts of magnesium oxide; 4 parts of magnesium chloride; 3 parts of calcium carbonate; 3 parts of vermiculite powder; Mix well with broken wood bran in the mixing tank; 2. Inject brine into the mixing agitator; 3. Add magnesium chloride, vermiculite powder, auxiliary materials and appropriate amount of water into the brine tank in proportion, and stir evenly to obtain brine 4. Put magnesium oxide and calcium carbonate into the mixing agitator, and inject the brine with the agricultural and forestry materials that have been processed into finely divided materials, or add other materials to mix, and then stir and mix to form a slurry; 5. According to the needs of users 6. Put the mixed slurry prepared in step 4 into the mold on the molding machine or frame for filling and molding to produce primary products; maintenance and surface Whitening treatment: After the primary product is cured, it is demolded, the surface is...

Embodiment 2

[0043] Get the following raw materials and parts by weight: 50 parts of magnesium oxide; 10 parts of magnesium chloride; 6 parts of calcium sulfate; 3 parts of vermiculite powder; 3 parts of titanium dioxide, 30 parts of broken wheat straw; First, add appropriate amount of water to the crushed wheat straw, and make pulp in the mixing tank; 2. Put magnesium oxide and calcium sulfate in the mixing agitator, and then inject the bittern with the crushed wheat straw that has been processed into fine pieces; 3. Add magnesium chloride , vermiculite powder, titanium dioxide and auxiliary materials and an appropriate amount of water are added to the brine pool in proportion, and stirred evenly to obtain brine; 4. In the mixing agitator, put magnesium oxide and calcium carbonate, and the The agricultural and forestry materials are injected with brine, or mixed with aluminum hydroxide powder and other materials, and then stirred and mixed to form a slurry; 5. Make a mold according to the ...

Embodiment 3

[0045] Get the following raw materials and parts by weight: 70 parts of magnesium oxide; 12 parts of magnesium chloride; 10 parts of calcium carbonate; 8 parts of mica powder; 20 parts of crushed bagasse; Add appropriate amount of water to the slag and make slurry in the mixing tank; 2. Put magnesium oxide and calcium carbonate in the mixing agitator, and then inject the bittern with the crushed bagasse that has been processed into fine pieces; 3. Add magnesium chloride, mica powder, Auxiliary materials and appropriate amount of water are added into the brine tank in proportion, and stirred evenly to obtain brine; 4. Put magnesium oxide and calcium carbonate in the mixing agitator, and then inject the brine with the agricultural and forestry materials that have been processed into fine pieces , or add antimony trioxide micropowder, glass fiber or other materials to mix, then stir and mix to form a slurry; 5. Make a mold according to the size, specification and shape required by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com