Polar crystal-form polyvinylidene fluoride and preparation method of composite thereof

A technology of polyvinylidene fluoride and composite materials, which is applied in the field of functional polymer materials and can solve problems such as the lack of cetyltrimethylammonium bromide to regulate the polar crystal form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

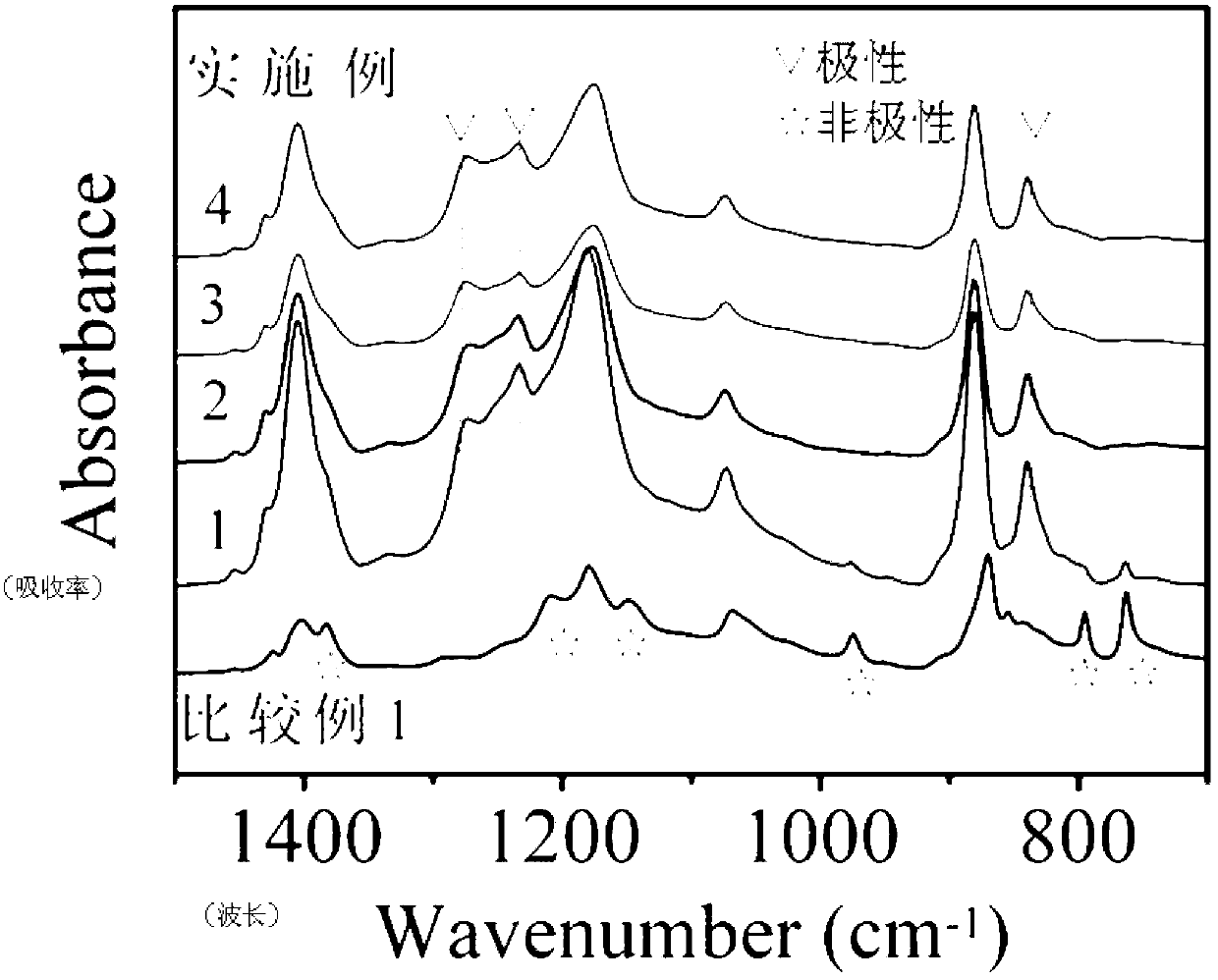

Embodiment 1-4

[0035] PVDF (Sigma-Aldrich427152; weight-average molecular weight Mw: 180000g / mol; number-average molecular weight Mn: 71000g / mol;) and CTAB (Chengdu Kelong Reagent Chemical Factory) were dispersed in DMF respectively, polyvinylidene fluoride and CTAB in The concentrations in the solvent were 0.1 g / ml and 0.05 mg / ml respectively. The two solutions were mixed in different proportions. The specific formulations are shown in Table 1, and the solvent was evaporated at 120°C.

[0036] Table 1

[0037] Example

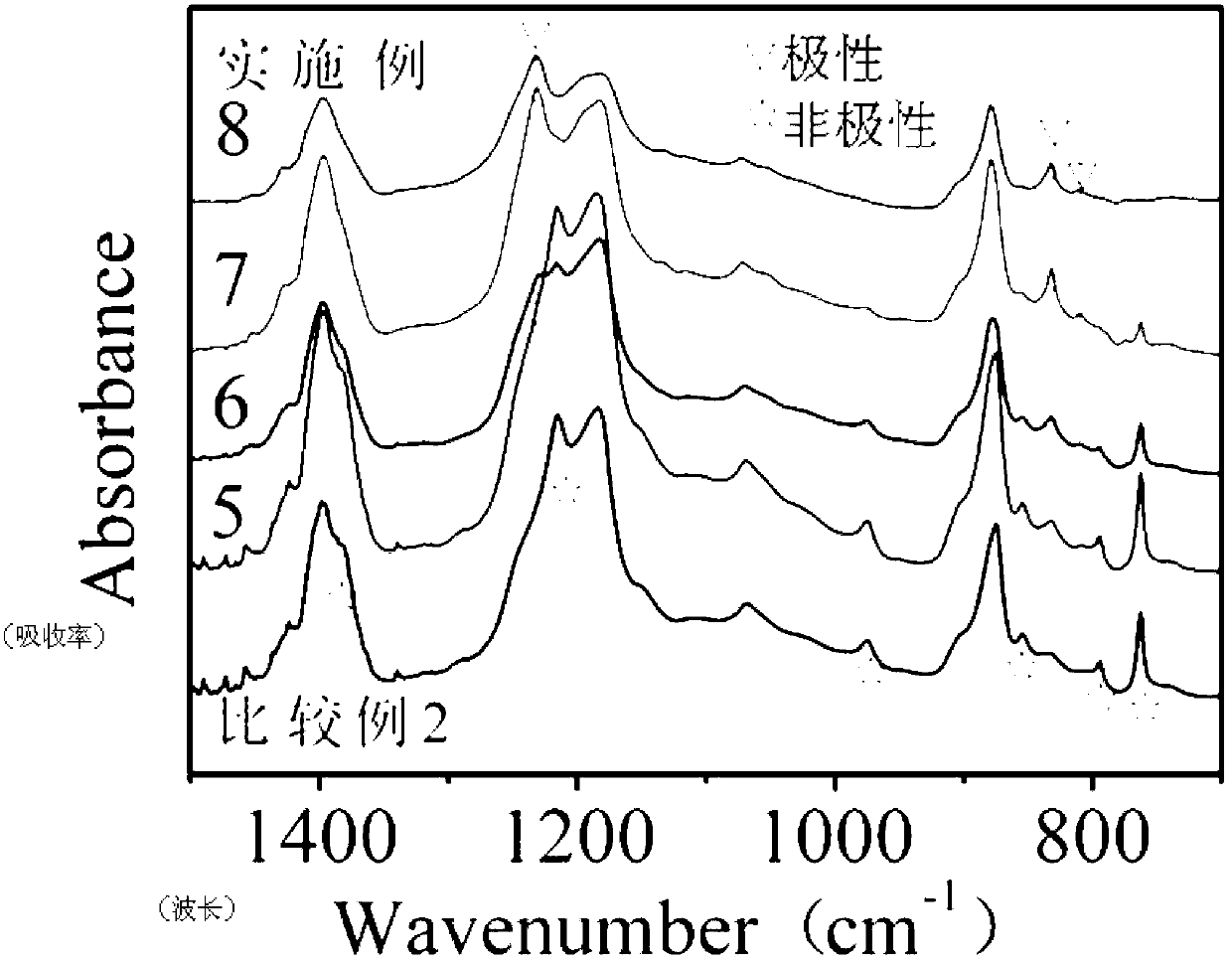

Embodiment 5-8

[0039] Melt the film sample obtained by evaporating the solvent after mixing the solution with the same formula (see Table 2) as in Examples 1-4, heat to 220°C to eliminate the heat history for 10 minutes, cool down to 155°C for isothermal crystallization of the melt, and isothermally The crystallization time is 90min.

[0040] Table 2

[0041] Example

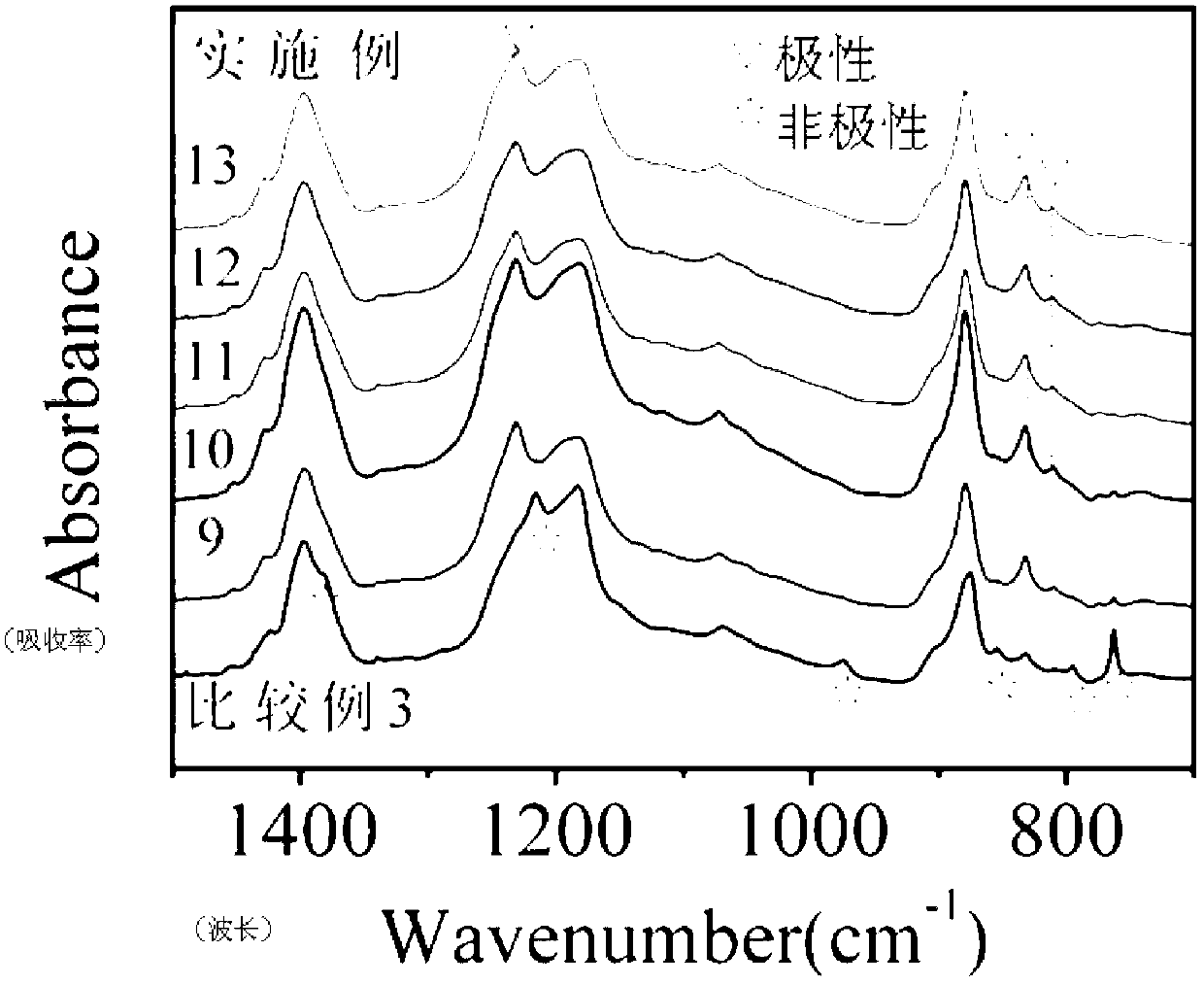

Embodiment 9-15

[0043] Disperse PVDF (FR903, Shanghai 3F New Materials Co., Ltd.), CTAB (Chengdu Kelong Reagent Chemical Factory) and graphite oxide (GO, self-made by Hummers method) in DMF respectively, and the concentration of PVDF, CTAB and GO in the solvent They are 0.05g / ml, 0.05mg / ml and 0.5mg / ml respectively. The three groups of dispersions were mixed in different proportions, and the specific formulations are shown in Table 3. After ultrasonic stirring for 1 hour, it was poured into deionized water for flocculation. The volume of deionized water was 10 times the volume of the solution, and the flocs were dried in a blast oven at 100°C for 48 hours, so that the solvent weight fraction was less than 0.01%. Then molded at 10MPa, 200℃. Eliminate thermal history at 220°C for 10 minutes, and crystallize isothermally at 160°C for 60 minutes.

[0044] table 3.

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight average molecular weight | aaaaa | aaaaa |

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com