Composite air purification coating material and preparation method thereof

A technology of air purification and air purification particles, which is applied in the field of composite air purification coatings and its preparation, can solve the problems of coating aging and inconspicuous air purification effect, and achieve the advantages of promoting adsorption, long-term air purification effect, high efficiency and Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] (1) Preparation of paint-coated samples for testing

[0040] In the present invention, in order to test the adsorption / photocatalytic performance of the prepared coating, the prepared coating is coated on different substrates, and the specific steps are as follows:

[0041] ① Cement substrate coating: Cut the cement substrate into small pieces of about 3.5cm×3.5cm, apply 3 to 5 layers of paint on the small pieces with a glass rod by roller coating method, and dry at room temperature for 1 day.

[0042] ②Glass substrate coating: Use 5 layers of adhesive tape to enclose a 5cm×9.5cm space on a glass piece of appropriate size, use the roller coating method to coat the film in the space with a glass rod, and dry at room temperature for 1 day to obtain a glass piece with 5 Coating film samples with the thickness of one layer of tape and an area of 5cm×9.5cm.

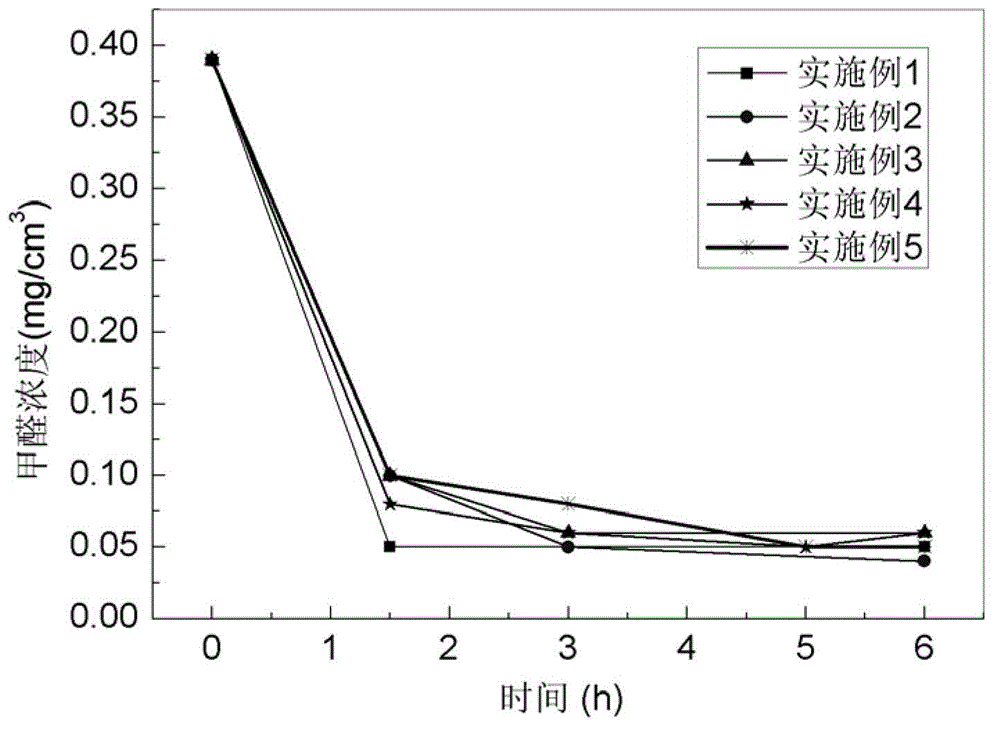

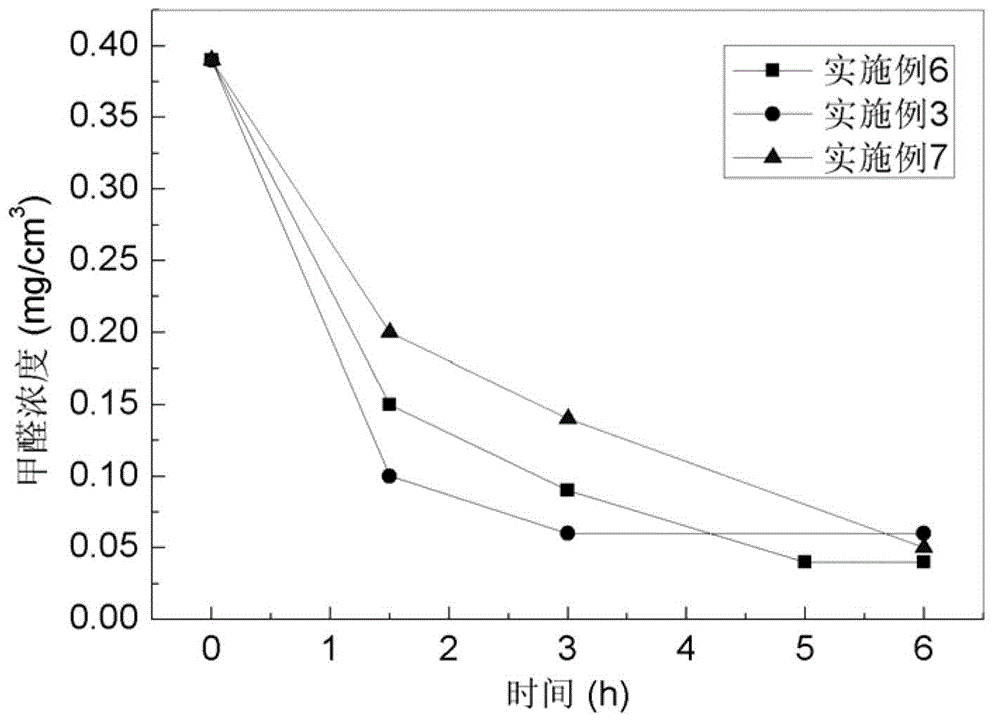

[0043] (2) Determination of adsorption / photocatalytic degradation performance test of cement substrate coating fil...

Embodiment 1

[0054] Preparation containing TiO 2 -SiO 2 Composite air-purifying coatings with composite aerogels:

[0055] ① with TiO 2 -SiO 2 Preparation of composite air-purifying coatings with composite airgel as adsorption / photocatalyst

[0056] Firstly, TiO was prepared by atmospheric pressure drying process. 2 -SiO 2 Composite airgel, the preparation method refers to the patent ZL200810011646.4, the specific process is as follows: using industrial water glass and titanium tetrachloride as raw materials, respectively prepare titanium tetrachloride aqueous solution and silicic acid solution, and mix the two in proportion to obtain Ti / TiO with a Si molar ratio of 4:1 2 -SiO 2 Composite sol, add hexamethyldisiloxane, trimethylchlorosilane and n-hexane to the sol, use n-hexane / trimethylchlorosilane for solvent replacement / surface modification after gelling, and finally pass 120 Drying at ~150°C under normal pressure to obtain TiO with a Ti / Si molar ratio of 4:1 2 -SiO 2 Composi...

Embodiment 2

[0062] Preparation containing SiO 2 Aerogel and WO 2 -TiO 2 Composite photocatalyst air purification coating:

[0063] ① WO 3 -TiO 2 Preparation of composite materials

[0064] Preparation of WO by hydrothermal method 3 -TiO 2 Composite photocatalyst, the specific process is as follows: using titanium sulfate and sodium tungstate as raw materials, first prepare titanium sulfate solution and tungstic acid solution, and mix the two solutions to obtain WO with a W / Ti molar ratio of 0.05:1. 3 -TiO 2 Precursor solution, which was transferred to an autoclave lined with polytetrafluoroethylene, and reacted at 190°C for 2 hours to obtain WO with a W / Ti molar ratio of 0.05:1. 3 5mol%-TiO 2 Composite photocatalyst powder.

[0065] ②Composite air purification paint preparation

[0066] Take 0.500g SiO 2 Airgel (SiO 2 Preparation method of airgel and TiO 2 -SiO 2 Composite airgel is similar, using industrial water glass as raw material, first prepare SiO 2 Sol, after gelli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com