Method for prolonging running period of hydrotreatment device

A technology of hydrotreating and operation cycle, applied in hydrotreating process, treating hydrocarbon oil, treating equipment corrosion/fouling, etc., can solve the problems of blocking catalyst pores, uneven liquid distribution, and local hot spots, etc. The effect of bed pressure drop, prolonging operation cycle and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

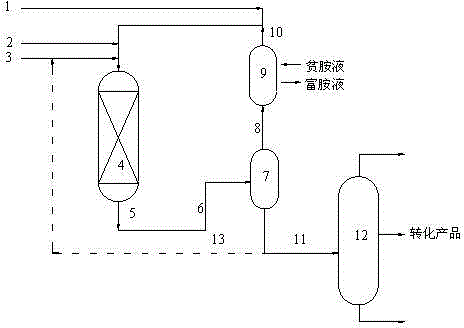

Image

Examples

Embodiment 1-3

[0032] The test was carried out on a hydrogenation experimental device imported from XYTEL Corporation of the United States. The catalyst used in the test was the hydrotreating catalyst FF-14 developed by the Fushun Petrochemical Research Institute. Hourly volume space velocity 0.6h -1 .

[0033] The properties of raw oil used in the test are listed in Table 2, and the properties of on-line cleaning diesel distillate oil are listed in Table 3.

[0034] Under standard operating conditions, the test device operated stably for 7,000 hours to obtain sulfur and nitrogen data of hydrogenated oil. Then reduce the temperature of each reaction to 200°C at 10°C / h, and at the same time -1 Introduce the 1:1 mixed oil of straight-run diesel oil and catalytic diesel oil into the device at a volume space velocity of 15 °C / h. Amide 30 μg / g. After operating at this temperature for 18 hours, the cleaning oil was circulated, the bed temperature of the reactor was reduced to 175°C, and CS wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com