Method for determining volatile organic compounds in polyvinyl acetate type water-based adhesive

A technology of polyvinyl acetate and organic compounds, applied in the direction of measuring devices, instruments, scientific instruments, etc., to achieve the effect of solving experimental errors, eliminating influence and interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

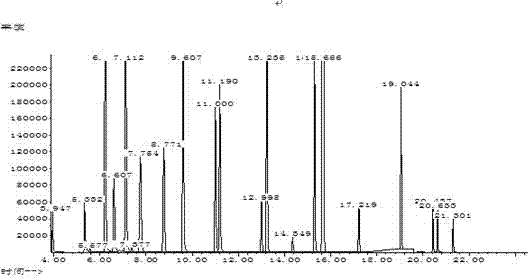

Image

Examples

preparation example Construction

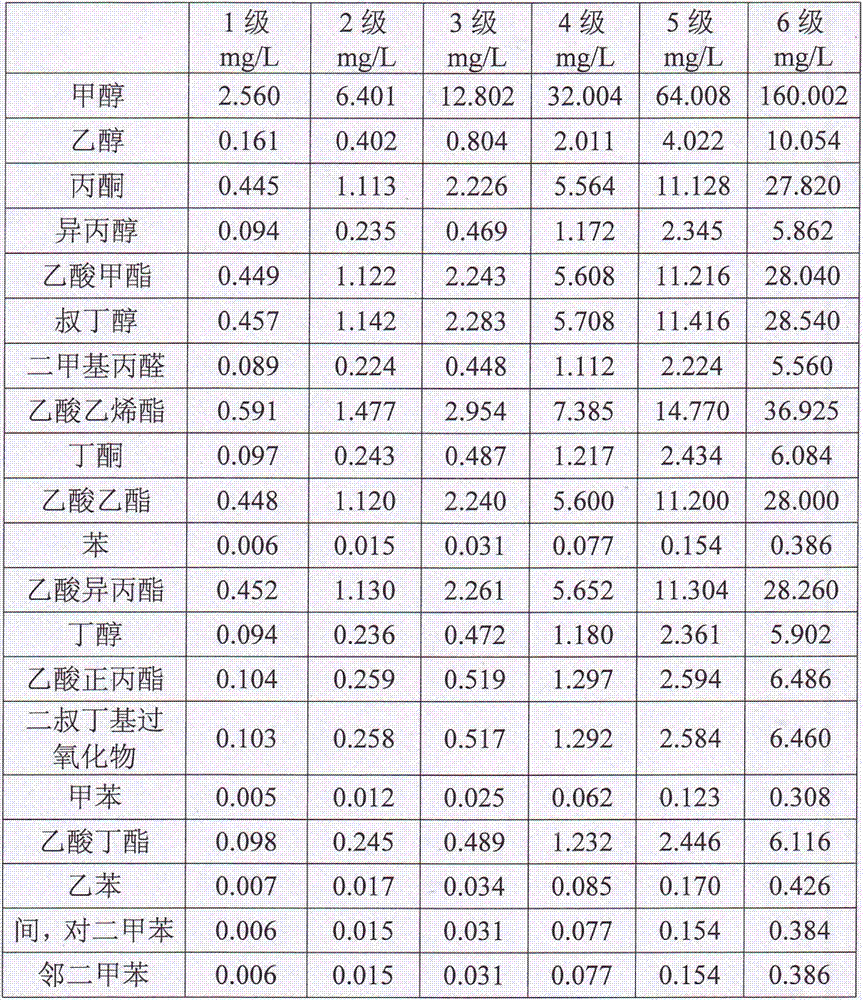

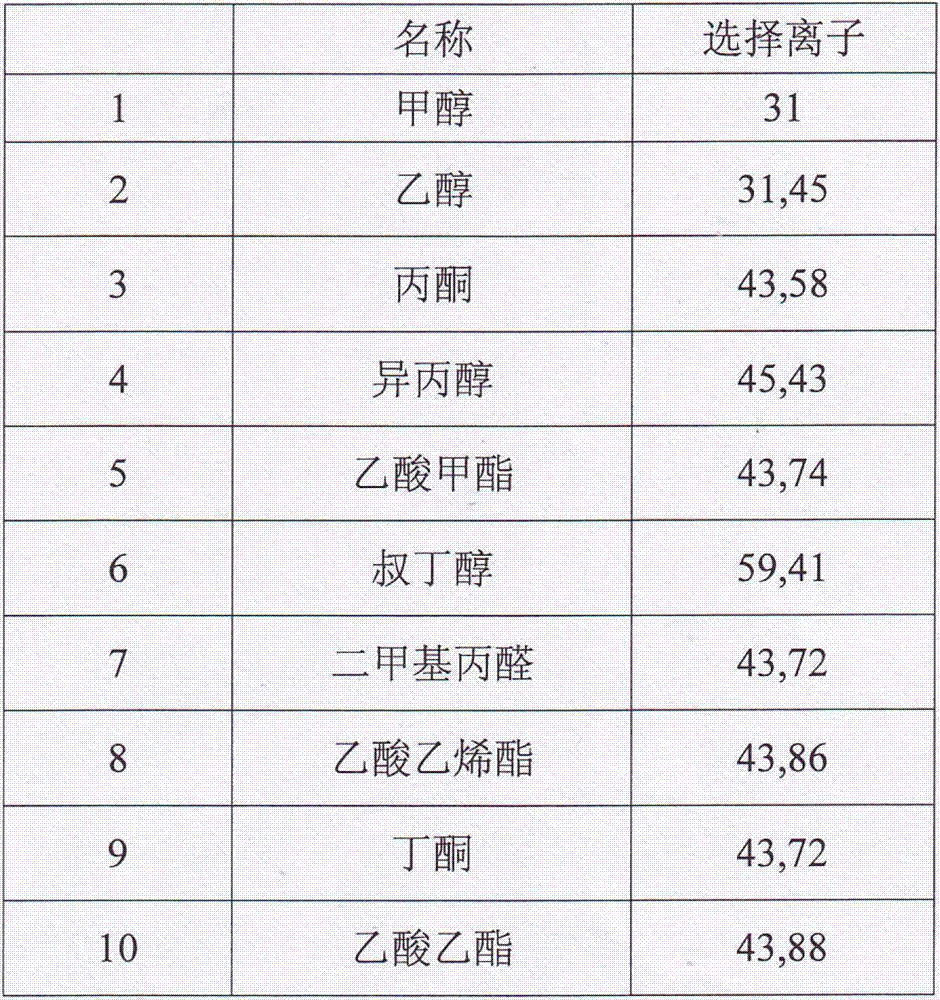

[0028] (1) Preparation of mixed standard stock solution I: Accurately weigh (accurate to 0.1mg) 15-20mg benzene, 15-20mg toluene, 15-20mg ethylbenzene, 15-20mg o-xylene, 15-20mg m-xylene or p-xylene, 300-500mg ethanol, 300-500mg isopropanol, 300-500mg dimethylpropanal, 300-500mg butanone, 300-500mg isopropyl acetate, 300-500mg butanol, 300-500mg n-acetic acid Propyl ester, 300~500mg butyl acetate, 300~500mg di-tert-butyl peroxide, 1.4g~1.5g acetone, 1.4g~1.5g methyl acetate, 1.4g~1.5g vinyl acetate, 1.4g~1.5 Put g ethyl acetate, 1.4g ~ 1.5g tert-butanol and 10g methanol in a 250mL volumetric flask, dilute to the mark with the prepared matrix calibration solution and mix evenly to obtain the mixed standard stock solution I;

[0029] (2) Preparation of mixed standard stock solution II: Accurately pipette 1mL of mixed standard stock solution I into a 100mL volumetric flask, dilute to the mark with the prepared matrix calibration solution and mix evenly to obtain mixed standard st...

Embodiment 1

[0065] In the assay method of the present embodiment: the concentration of the sodium chloride aqueous solution in the matrix calibration solution is 90 g / L; the headspace equilibration time for the sample and the standard sample is 30 min. The specific measurement results are shown in Table 5.

[0066] Table 5 The detection results of volatile substances in polyvinyl acetate water-based adhesive samples A and B

[0067] sample

[0068] Note: Not listed in Table 5 and "-" means that the volatile organic compounds were not detected.

Embodiment 2

[0070] In the assay method of the present embodiment: the concentration of the sodium chloride aqueous solution in the matrix calibration solution is 120 g / L; the headspace equilibration time for the sample and the standard sample is 40 min. The specific measurement results are shown in Table 6.

[0071] Table 6 The detection results of volatile substances in polyvinyl acetate water-based adhesive samples C and D

[0072]

[0073]

[0074] Note: Not listed in Table 6 and "-" means that the volatile organic compounds were not detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com