Method for producing amino acid liquid fertilizer by processing wastewater via tilapias

A liquid fertilizer and waste water processing technology, which is applied in the direction of sewage/sludge fertilizer, organic fertilizer, fertilization device, etc., can solve the problems of untimely treatment, waste of resources, pollution of the environment, etc., and achieve low production cost, small investment, and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

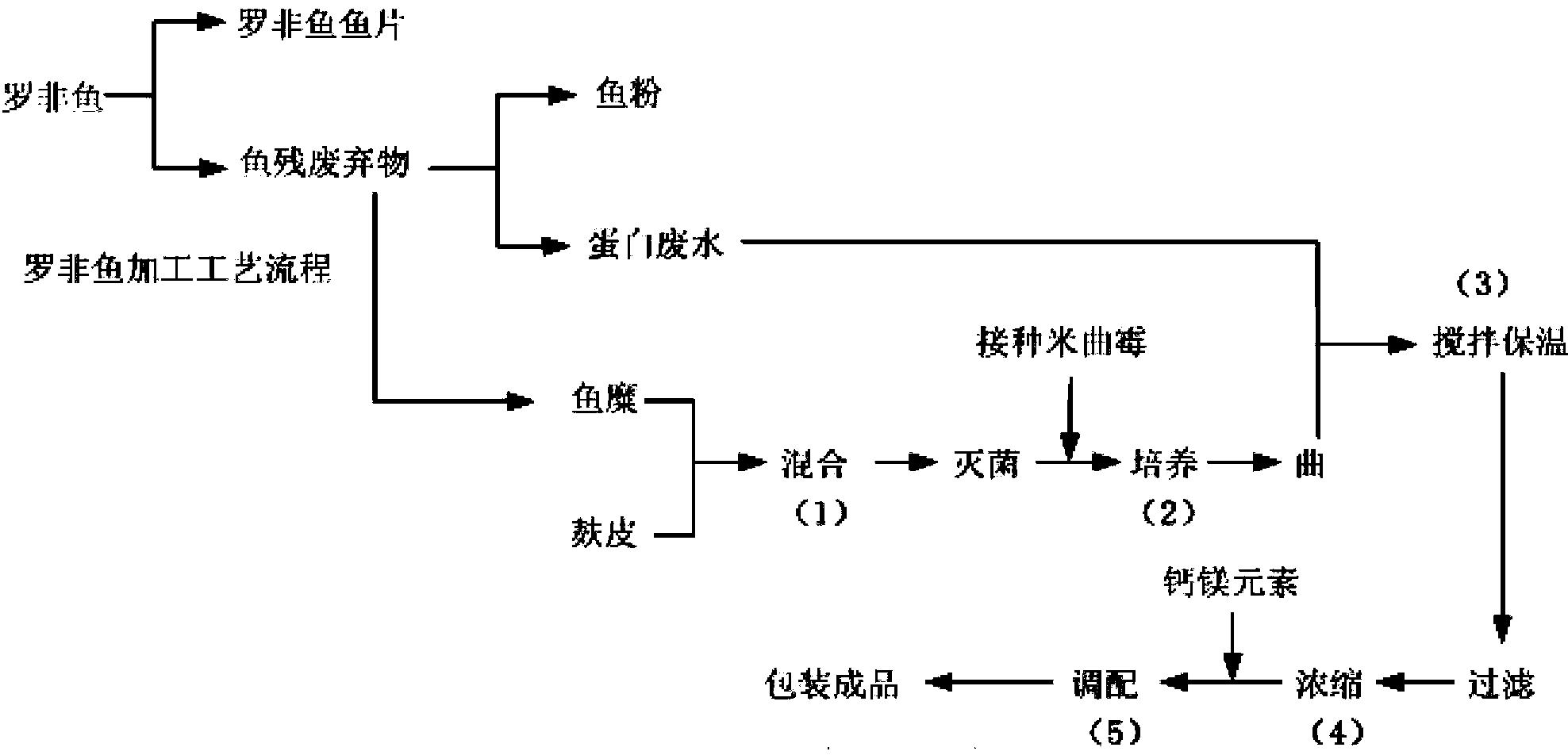

[0018] A method for producing amino acid liquid fertilizer with tilapia processing wastewater, comprising the following steps:

[0019] (1) Culture medium preparation process

[0020] Take the processed fish residues of tilapia, grind them into surimi with a pulverizer, take the surimi and bran, mix the two thoroughly at a weight ratio of 3:1, and then put the mixture at 130°C Sterilize under high pressure steam for 14 minutes, cool to room temperature to obtain solid medium, set aside;

[0021] (2) Inoculation and cultivation process

[0022] After cultivating Aspergillus oryzae on the slant of the test tube, use sterile water to make a concentration of 1×10 8 Aspergillus oryzae spore suspension of each / ml; Get the solid medium that step (1) obtains, inoculate 1ml of Aspergillus oryzae spore suspension in every 100g of solid medium; Then under 36 ℃, solid fermentation culture 49 hours, standby;

[0023] (3) Enzymolysis process

[0024] Take 100g of the medium cultured in ...

Embodiment 2

[0029] A method for producing amino acid liquid fertilizer with tilapia processing wastewater, comprising the following steps:

[0030] (1) Culture medium preparation process

[0031] Take the processed fish residues of tilapia, grind them into surimi with a pulverizer, take the surimi and bran, and mix them well according to the ratio of 3:1 by weight, and then put the mixture at 121℃ Sterilize under high pressure steam for 15 minutes, cool to room temperature to obtain a solid medium, and set aside;

[0032] (2) Inoculation and cultivation process

[0033] After cultivating Aspergillus oryzae on the slant of the test tube, use sterile water to make a concentration of 1×10 8 Aspergillus oryzae spore suspension of each / ml; Get the solid medium that step (1) obtains, inoculate 1ml of Aspergillus oryzae spore suspension in every 100g of solid medium; Then under 37 ℃, solid fermentation culture 48 hours, standby;

[0034] (3) Enzymolysis process

[0035] Take 100g of the medi...

Embodiment 3

[0040] A method for producing amino acid liquid fertilizer with tilapia processing wastewater, comprising the following steps:

[0041] (1) Culture medium preparation process

[0042] Take the processed fish residues of tilapia, grind them into surimi with a pulverizer, take the surimi and bran, mix the two thoroughly at a weight ratio of 3:1, and then put the mixture at 120°C Sterilize under high pressure steam for 16 minutes, cool to room temperature to obtain a solid medium, and set aside;

[0043] (2) Inoculation and cultivation process

[0044] After cultivating Aspergillus oryzae on the slant of the test tube, use sterile water to make a concentration of 1×10 8 Aspergillus oryzae spore suspension of each / ml; Get the solid medium that step (1) obtains, inoculate 1ml of Aspergillus oryzae spore suspension in the solid medium of every 100g; Then under 38 ℃, solid fermentation culture 47 hours, standby;

[0045] (3) Enzymolysis process

[0046] Take 100g of the medium cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com