Method for preparing special fertilizer by treating kitchen waste, sludge and domestic waste in one machine

A technology for domestic waste and kitchen waste, applied in the treatment of biological organic parts, waste fuel, etc., can solve the problems of difficult sales, long fermentation time, inability to remove cadmium, etc., and achieve the effect of saving separation costs and saving desalination materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

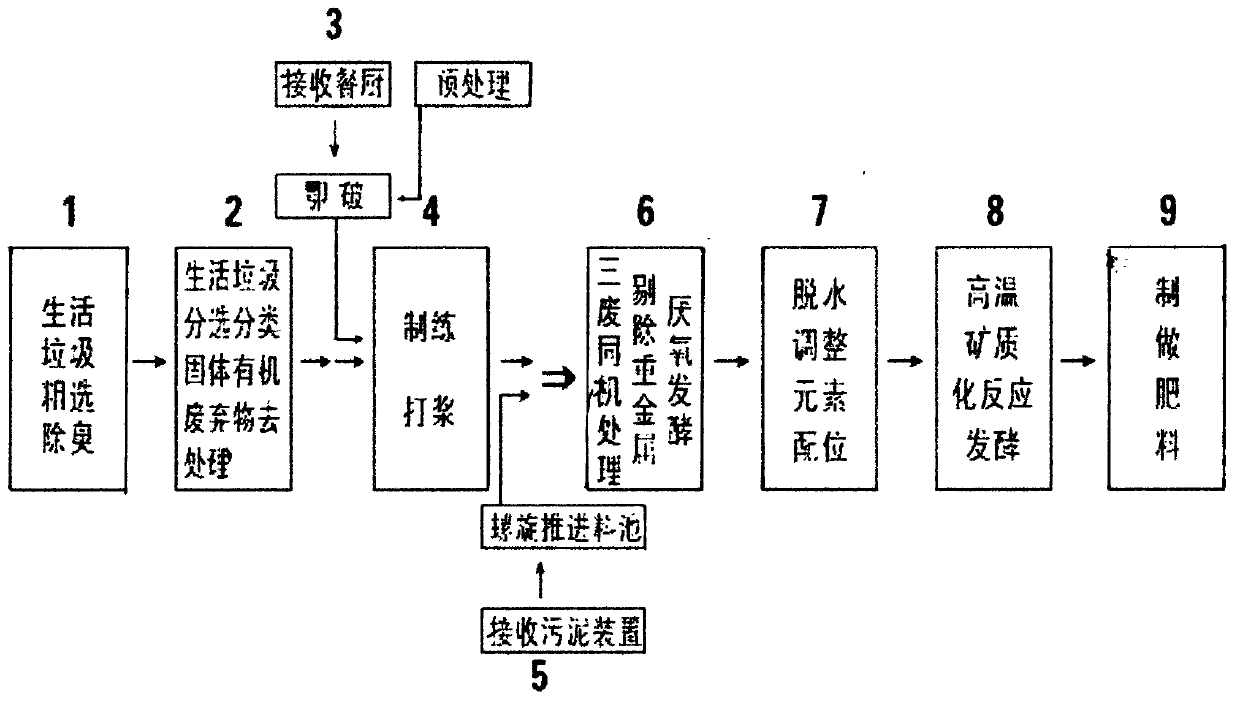

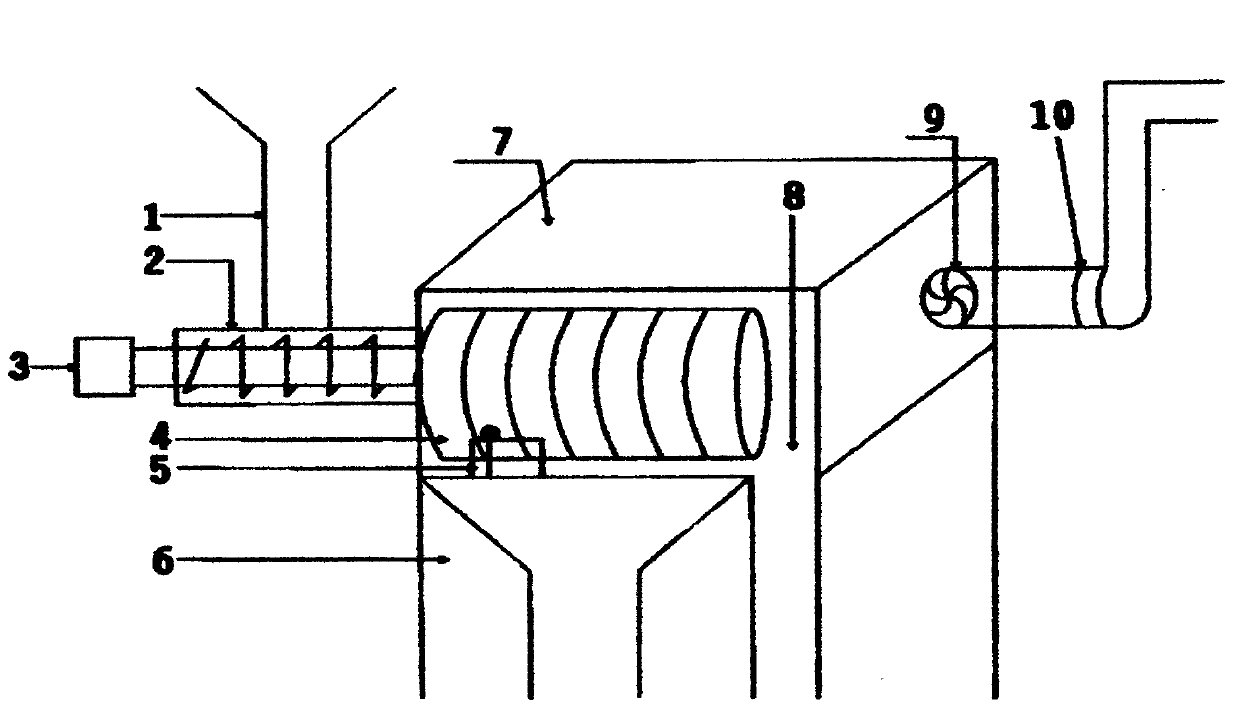

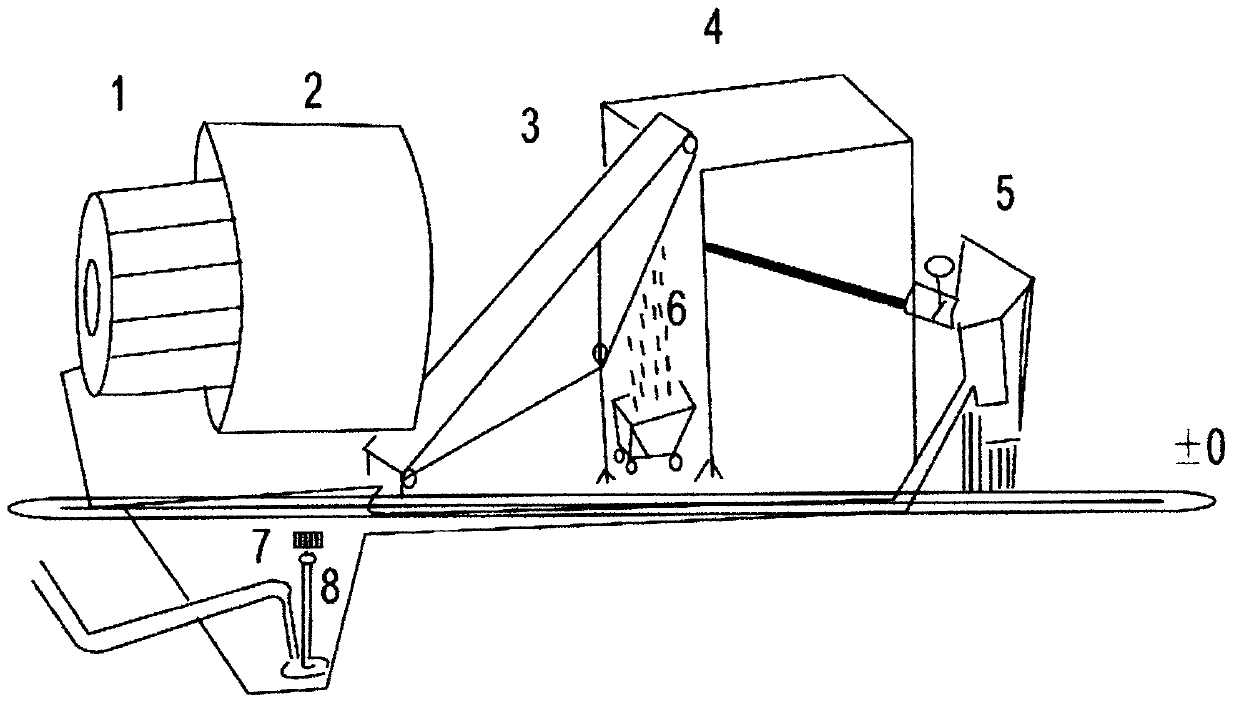

[0035] Composting process of food waste sludge and domestic waste ( figure 1 ): Household garbage rough separation and deodorization - Sorting out plastics and scrap metal - Adding food waste crushing slurry in the form of mixing water while making organic waste into pulp - Obtaining a homogeneous slurry and adding sludge slurry to mix Stir evenly—pump in and remove heavy metals, dissolve dioxins and anaerobic fermentation equipment for harmless treatment—extrude dehydration, adjust carbon-nitrogen ratio, carbon-phosphorus ratio and pH value and adjust materials—high-temperature mineralization reaction ferment thermophilic bacteria Phagocytosis and decomposition of dioxins and killing pathogenic bacteria to produce raw fertilizers - two element coordination to produce microbial organic fertilizers and special fertilizers for various crops.

[0036] Rough selection and deodorization: Household garbage is sent directly to the rough selection and deodorization workshop. The wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com