N-propanol refining technology

A technology of n-propanol, which is applied in the field of clean and energy-saving refining technology, can solve the problems of reducing the yield of n-propanol, environmental pollution, and separation difficulties, and achieves the advantages of saving reprocessing costs, improving product quality, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

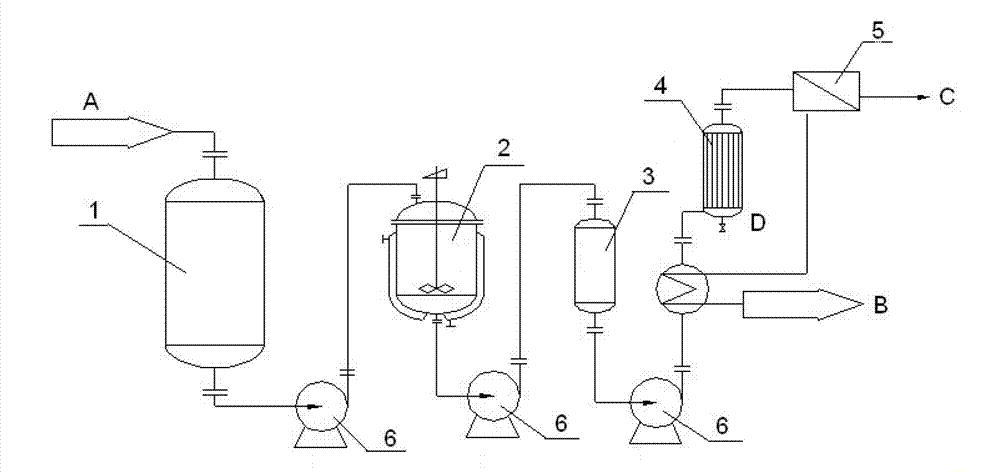

[0019] Such as figure 1 Shown, a kind of n-propanol refining process comprises the following steps: will be stored in crude propanol raw material storage tank 1 and come from the n-propanol crude liquid A of reaction process, in reactor 2, adjust by adding sodium hydroxide NaOH, Make it pH=8, and then pump it into the distillation tower 4 through the feed pump 6 for heating and distillation. The temperature of the bottom of the distillation tower is controlled at 90-115°C, and the temperature at the top of the tower is controlled at 90-105°C. The n-propanol vapor containing 15% water obtained from the top of the distillation tower enters the pervaporation membrane separation unit 5 for alcohol-water separation. The separation unit 5 is a membrane separator composed of 10 sets of NaA molecular sieve membranes, and the measured pressure of the feed liquid is 0.25MPa , the pressure on the permeate side is controlled at 2000Pa, the temperature of the feed liquid in the pervaporati...

Embodiment 2

[0021] Such as figure 1 Shown, a kind of n-propanol refining process comprises the following steps: will be stored in the thick n-propanol thick liquid A of reaction process in crude propanol raw material storage tank 1, by adding sodium hydroxide NaOH adjustment in reactor, make Its pH=9, and then pumped into the distillation tower 4 through the feed material 6 for heating and distillation. The temperature of the bottom of the distillation tower is controlled at 115-125°C, and the temperature at the top of the tower is controlled at 105-115°C. The n-propanol vapor with a water content of 5% from the top of the distillation tower enters the pervaporation membrane separation unit 5 for alcohol-water separation. The separation unit 5 is a membrane separator composed of 5 sets of NaA molecular sieve membranes, and the measured pressure of the feed liquid is 0.2 MPa, the permeate side pressure is controlled at 1700Pa, the feed liquid temperature of the pervaporation membrane separ...

Embodiment 3

[0023] Such as figure 1 Shown, a kind of n-propanol refining process comprises the following steps: will be stored in crude propanol raw material storage tank 1 and come from the n-propanol crude liquid A of reaction process, in reactor 2, adjust pH by adding potassium hydroxide KOH =8, then pumped into the distillation tower 4 for heating and distillation, the temperature of the bottom of the distillation tower is controlled at 125-150°C, and the temperature at the top of the tower is controlled at 115-130°C. The n-propanol vapor with a water content of 8% from the top of the distillation tower enters the pervaporation membrane separation unit 5 for alcohol-water separation. The separation unit 5 is a membrane separator composed of 15 sets of NaA molecular sieve membranes, and the measured pressure of the feed liquid is 0.1 MPa, the permeate side pressure is controlled at 3000Pa, the feed liquid temperature of the pervaporation membrane separator is controlled at 125-150°C, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com