Processing method of high-obdurability and high-conductivity copper magnesium alloy

A technology of copper-magnesium alloy and processing method, which is applied in the processing field of high-strength, toughness and high-conductivity copper-magnesium alloy, can solve the problems of low conductivity and cumbersome processing methods of Cu-Cr alloy, and achieve the purpose of maintaining conductivity, improving strength and toughness, and processing The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

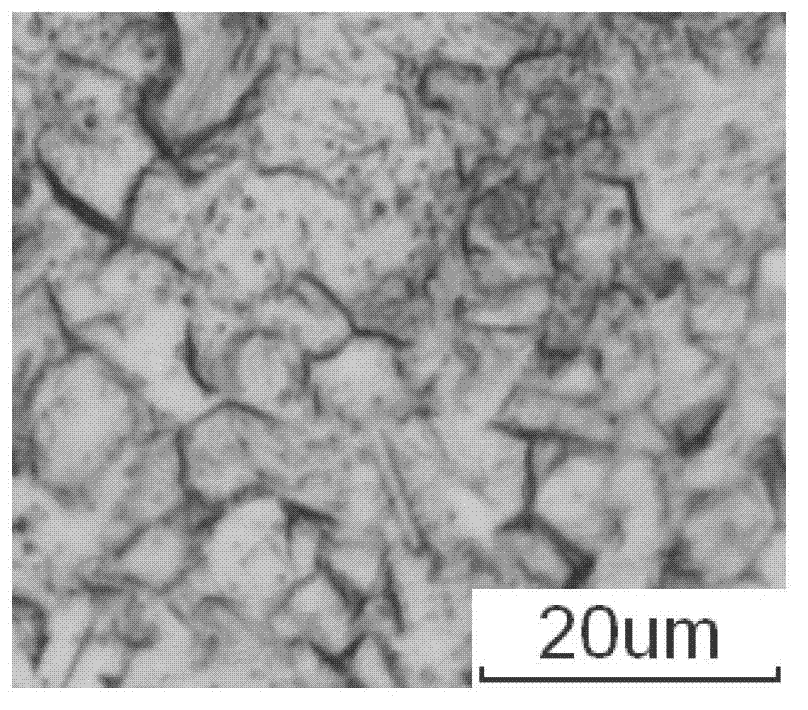

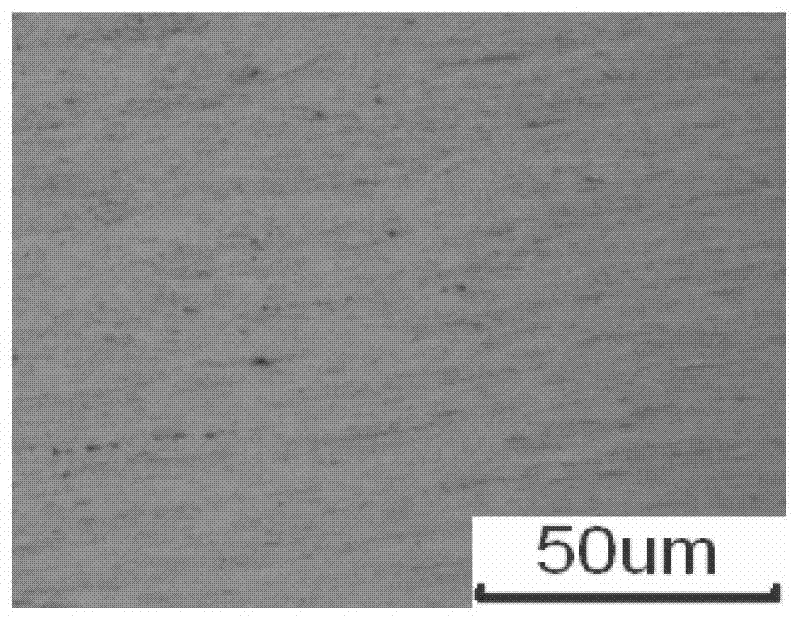

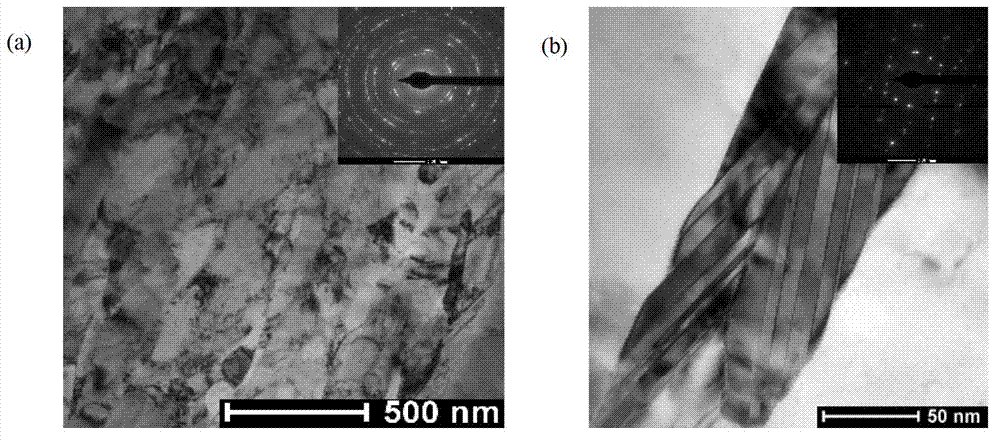

[0023] Electrolytic copper and pure magnesium were selected as raw materials to prepare a copper-magnesium alloy with a magnesium content of 0.2%, and the up-drawing continuous casting technology and continuous hot extrusion were used to obtain a thermally deformed Cu-0.2wt%Mg alloy, that is, a copper-magnesium alloy rod. The magnesium in it is mainly in the form of solid solution in the magnesium matrix, and the average grain size is 5~8μm (see figure 1 ), the grain morphology is equiaxed. After 16 passes of continuous equal-channel angular extrusion at a temperature of 573K, the equal-channel angle in the mold is 90°, the alloy structure is significantly refined, and the grains are distributed in bands, with a length of about 1 μm and a width of about 200 nm (see figure 2 and image 3 ), the dislocation density inside the grains is low, and there are some twins. Due to the special microstructural characteristics in the ultrafine-grained copper-magnesium alloy, the tensile...

Embodiment 2

[0025] Electrolytic copper and pure magnesium were selected as raw materials to produce a copper-magnesium alloy with a magnesium content of 0.4%. Using upward continuous casting technology and continuous hot extrusion processing, a thermally deformed Cu-0.4wt%Mg alloy, namely a copper-magnesium alloy rod, was obtained. The magnesium in it is mainly in the form of solid solution in the magnesium matrix, and the average grain size is 8~10μm (see Image 6 ), the grain morphology is equiaxed. After 8 passes of continuous equal-channel angular extrusion at a temperature of 273K, the equal-channel angle in the mold is 120°, the alloy structure is obviously refined, and the grains are distributed in bands (see Figure 7 ). Compared with Cu-0.2wt%Mg alloy, the increase of magnesium content increases the effect of solid solution strengthening, so after 8 passes of continuous equal channel angular extrusion at 273K temperature, its tensile strength reaches 589MPa, and its elongation r...

Embodiment 3

[0027] The difference between embodiment 3 and embodiment 1 is only that electrolytic copper and magnesium are selected as raw materials to make a copper-magnesium alloy with a magnesium content of 0.1%, the extrusion temperature is 473K, and the equal passage angle in the mold is 100°, and the rest of the operations are the same Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com