Nickel-copper-rare earth-aluminum oxide catalysis separation composite film and preparation method and application thereof

A technology of aluminum oxide and composite membrane, which is applied in chemical instruments and methods, hydrogen separation, semipermeable membrane separation, etc., and can solve problems such as limited industrial application and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for preparing a nickel-copper-rare earth-aluminum oxide catalytic separation composite membrane, specifically comprising the following steps:

[0044] (1) Put the 90mm×60mm×250μm porous through-hole anodized aluminum oxide film into a 500mL beaker, add 420mL of pure water, clean it with ultrasonic waves for 30min, take out the porous through-hole anodized aluminum oxide film, and dry it in an oven at 100°C 0.5h, burn in a high-temperature furnace at 800°C for 5h, take out the porous through-hole anodic aluminum oxide film and cool to room temperature;

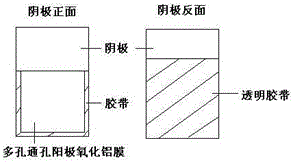

[0045] (2) Use transparent tape to paste the above-mentioned porous through-hole anodized aluminum film to be plated on the electrolytic nickel plate of 150mm×60mm×2mm, and paste the transparent tape on the reverse side of the electrolytic nickel plate, specifically as follows figure 1 As shown, that is, firstly, the above-mentioned porous through-hole anodized aluminum film to be plated is placed on one end of ...

Embodiment 2

[0057] A method for preparing a nickel-copper-rare earth-aluminum oxide catalytic separation composite membrane, specifically comprising the following steps:

[0058] (1) Put a 90mm×60mm×250μm porous through-hole anodized aluminum oxide film into a 500mL beaker, add 420mL of pure water, clean it with ultrasonic waves for 5min, take out the porous through-hole anodized aluminum oxide film, and dry it in an oven at 50°C 5h, burn in a high-temperature furnace at 1100°C for 0.5h, take out the porous through-hole anodized aluminum film and cool it to room temperature;

[0059] (2) Paste the above-mentioned treated porous through-hole anodic aluminum oxide film to be plated on an electrolytic copper plate of 150 mm × 60 mm × 2 mm with double-sided adhesive tape, and stick a transparent tape on the reverse side of the electrolytic copper plate, specifically the same as in Example 1 ;

[0060] (3) Weigh 5.7631g of gadolinium oxide in a 100mL small beaker, add 30mL of concentrated nit...

Embodiment 3

[0072] A method for preparing a nickel-copper-rare earth-aluminum oxide catalytic separation composite membrane, specifically comprising the following steps:

[0073] (1) Put a 90mm×60mm×250μm porous through-hole anodized aluminum oxide film into a 500mL beaker, add 420mL of pure water, clean it with ultrasonic waves for 17min, take out the porous through-hole anodized aluminum oxide film, and dry it in an oven at 85°C 2h, burn in a high-temperature furnace at 900°C for 3h, take out the porous through-hole anodized aluminum film and cool it to room temperature;

[0074] (2), the above-mentioned treated porous through-hole anodic aluminum oxide film to be plated is pasted on a steel plate of 150mm * 60mm * 2mm with scotch tape, and the scotch tape is pasted on the back of the steel plate, specifically the same as in Example 1;

[0075](3) Weigh 0.5852g of praseodymium oxide into a 100mL small beaker, add 15mL of concentrated nitric acid under stirring, heat to dissolve it, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com