Preparation method of xanthate macro-pore dextrangel adsorbent

A dextran gel and xanthate-based technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc. The report on the preparation method and application of polysaccharide gel, the easy removal of discharged wastewater, and the low rate of repeated use have achieved good physical and chemical stability, excellent mechanical stability, and low production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

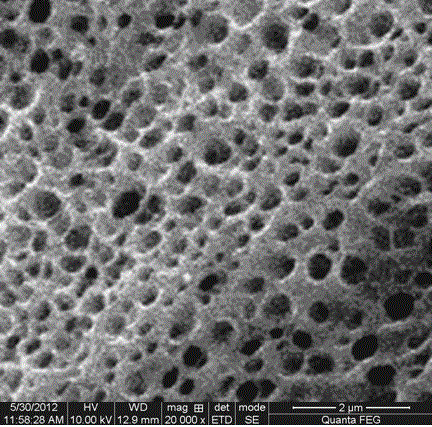

Image

Examples

Embodiment 1

[0021] (1) Preparation of macroporous dextran gel, which is characterized by: in the reactor, soak the dextran gel in distilled water for 40 hours, fully wash with distilled water until neutral, filter, and place it at -12°C for 48 hours to freeze quickly. Take it out and thaw it at room temperature to obtain a macroporous dextran gel;

[0022] (2) Preparation of alkalized macroporous dextran gel, the characteristics are: in the reactor, dissolve 10g of sodium hydroxide in 50mL of water, lower the sodium hydroxide solution to room temperature, add 20g of macroporous dextran gel , keep the temperature within the range of 60°C, stir and react for 40 minutes, cool to room temperature, filter, wash, and dry to obtain alkalized macroporous dextran gel;

[0023] (3) The preparation of xanthan acid-based macroporous dextran gel is characterized by: adding carbon disulfide (CS) with a concentration of 60% in the reactor 2 ) Chloroform solution 20mL, add 6g alkalized macroporous dextr...

Embodiment 2

[0025] (1) Preparation of macroporous dextran gel, which is characterized by: in the reactor, soak the dextran gel in distilled water for 40 hours, fully wash it with distilled water until it is neutral, filter it, and place it at -18°C for 30 hours to freeze quickly. Take it out and thaw it at room temperature to obtain a macroporous dextran gel;

[0026] (2) Preparation of alkalized macroporous dextran gel, which is characterized by: in the reactor, dissolve 12g of sodium hydroxide in 50mL of water, lower the sodium hydroxide solution to room temperature, add 30g of macroporous dextran gel , keep the temperature within the range of 55°C, stir and react for 60 minutes, cool to room temperature, filter, wash, and dry to obtain alkalized macroporous dextran gel;

[0027] (3) The preparation of xanthan acid-based macroporous dextran gel is characterized by: adding 70% carbon disulfide (CS 2 ) Chloroform solution 30mL, add 15g alkalized macroporous dextran gel, lower the system ...

Embodiment 3

[0029](1) Preparation of macroporous dextran gel, which is characterized by: in the reactor, soak the dextran gel in distilled water for 48 hours, fully wash it with distilled water until it is neutral, filter it, and place it at -15°C for 40 hours to freeze quickly. Take it out and thaw it at room temperature to obtain a macroporous dextran gel;

[0030] (2) Preparation of alkalized macroporous dextran gel, which is characterized by: in a reactor, dissolve 15g of sodium hydroxide in 50mL of water, lower the sodium hydroxide solution to room temperature, add 35g of macroporous dextran gel , keep the temperature within the range of 50°C, stir and react for 45 minutes, cool to room temperature, filter, wash, and dry to obtain alkalized macroporous dextran gel;

[0031] (3) The preparation of xanthan acid-based macroporous dextran gel is characterized by: adding 80% carbon disulfide (CS 2 ) Chloroform solution 30mL, add 18g alkalized macroporous dextran gel, lower the system tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com