Composite thermally-conductive thin layer and preparation method and application thereof

A thin-layer, heat-conducting medium technology, applied in the field of preparation of functional composite materials, can solve the problems of poor thermal conductivity, decreased impact and delamination performance, and difficult dispersion of carbon nanotubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The implementation process of the technical solution of the present invention is as follows:

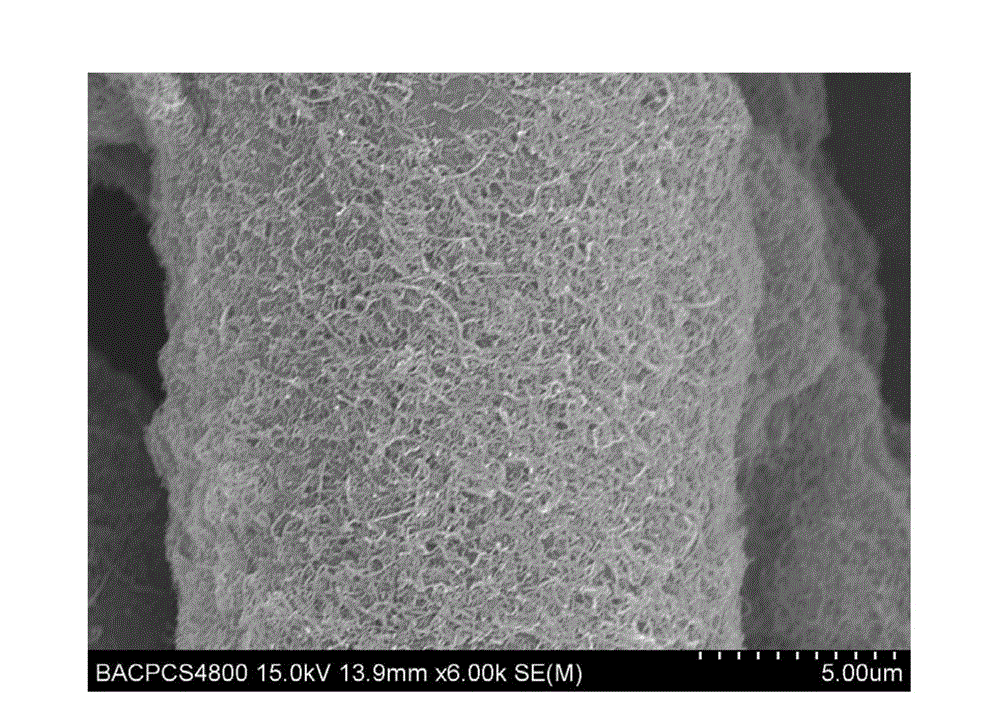

[0027] (1-1) Disperse carbon nanotubes or graphene in ethanol or isopropanol or acetone or ethylene glycol to form a dispersion with a concentration of 5 mg / mL or 15 mg / mL;

[0028] (1-2) Nylon non-woven fabric with a thickness of 53 μm and an area density of 14 g / m2 or a thickness of 25 μm and an area density of 8 g / m 2 Polyether ether ketone non-woven fabric or thickness of 75μm, surface density of 26g / m 2 Polyimide non-woven fabric with a thickness of 15μm and a surface density of 7g / m 2 Polyethersulfone non-woven fabric or thickness of 55μm, area density of 28g / m 2 Immerse the aramid non-woven fabric obtained in the above step (1-1) into the dispersion liquid obtained in the above step (1-1), pull it out of the liquid surface and dry it or dry it, turn it over and then dip it twice to obtain a uniformly loaded carbon nanotube or graphene Thermally conductive polymer non...

Embodiment 2

[0033] The implementation process of the technical solution of the present invention is as follows:

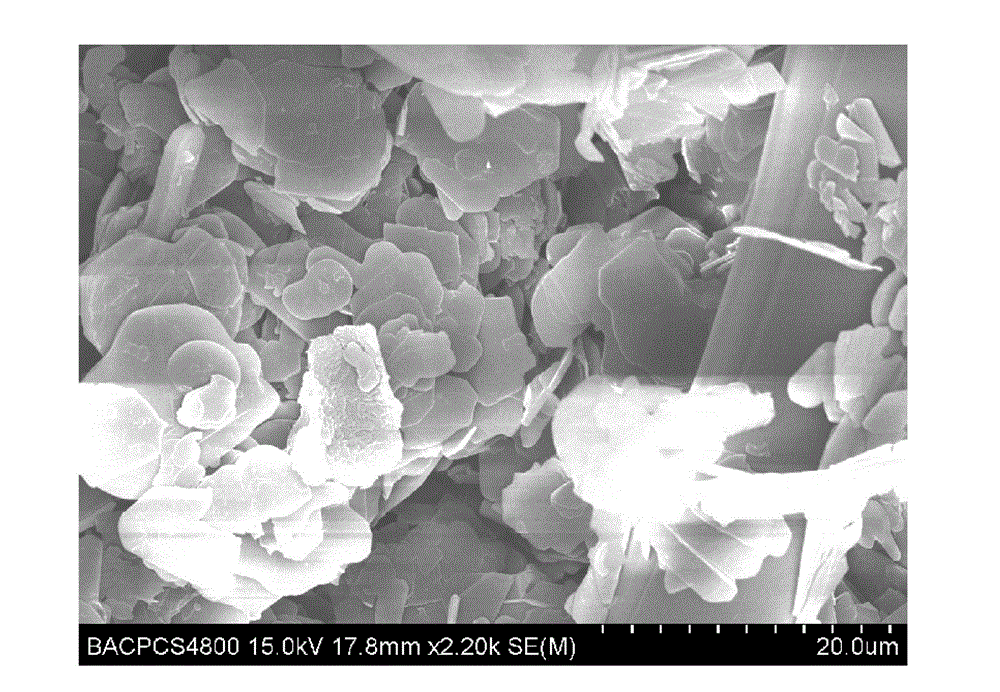

[0034] (2-1) Disperse flaky boron nitride powder or diamond micropowder or flake graphite powder in methanol or ethanol to form a 25 mg / mL or 40 mg / mL or 95 mg / mL dispersion.

[0035] (2-2) Use the method of filtering the dispersion liquid in step (2-1) to be loaded to a thickness of 35 μm and a surface density of 14 g / m 2 Nylon fabric with a thickness of 25μm and a surface density of 11g / m 2 Polyether ether ketone fabric or thickness of 45μm, area density of 18g / m 2 On the polyimide fabric, obtain the heat conduction thin layer fabric that heat conduction medium attaches;

[0036](2-3) Lay the thermally conductive polymer porous films obtained above on one by one between the layers of continuous carbon fiber reinforced satin or plain weave or unidirectional or a mixture of the above weaving methods, carbon fiber T700, 12K, After shaping, a prefabricated composite material ...

Embodiment 3

[0039] The implementation process of the technical solution of the present invention is as follows:

[0040] (3-1) Co-disperse graphene, carbon nanotubes or carbon nanotubes, flake boron nitride powder in butanol or methanol or tetrahydrofuran to form a dispersion, the concentrations are: graphene concentration 6mg / mL, carbon nanometer Tube concentration is 9mg / mL, or carbon nanotube concentration is 8mg / mL, flake boron nitride powder concentration is 20mg / mL.

[0041] (3-2) Spray the above-mentioned co-dispersion of heat-conducting medium to a thickness of 75 μm and an area density of 26 g / m 2 The polyimide fiber non-woven fabric or the thickness is 28μm, the area density is 11g / m 2 Carbon nanofiber non-woven fabric with a thickness of 5μm and a surface density of 5g / m 2 On the carbon nanotube non-woven fabric, a composite heat-conducting thin layer of graphene, carbon nanotubes or carbon nanotubes and flake boron nitride powder is obtained;

[0042] (3-3) Place the heat-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com