Yttrium-doped aluminum nitride diluted magnetic semiconductor quasi-array microtube and fabrication method of microtube

A technology of dilute magnetic semiconductors and micron tubes, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of consuming a lot of time and financial resources, and achieve the effects of less energy consumption, high purity, and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]Example 1 The best overall process for preparing Y-doped AlN dilute magnetic semiconductor quasi-array microtube structure

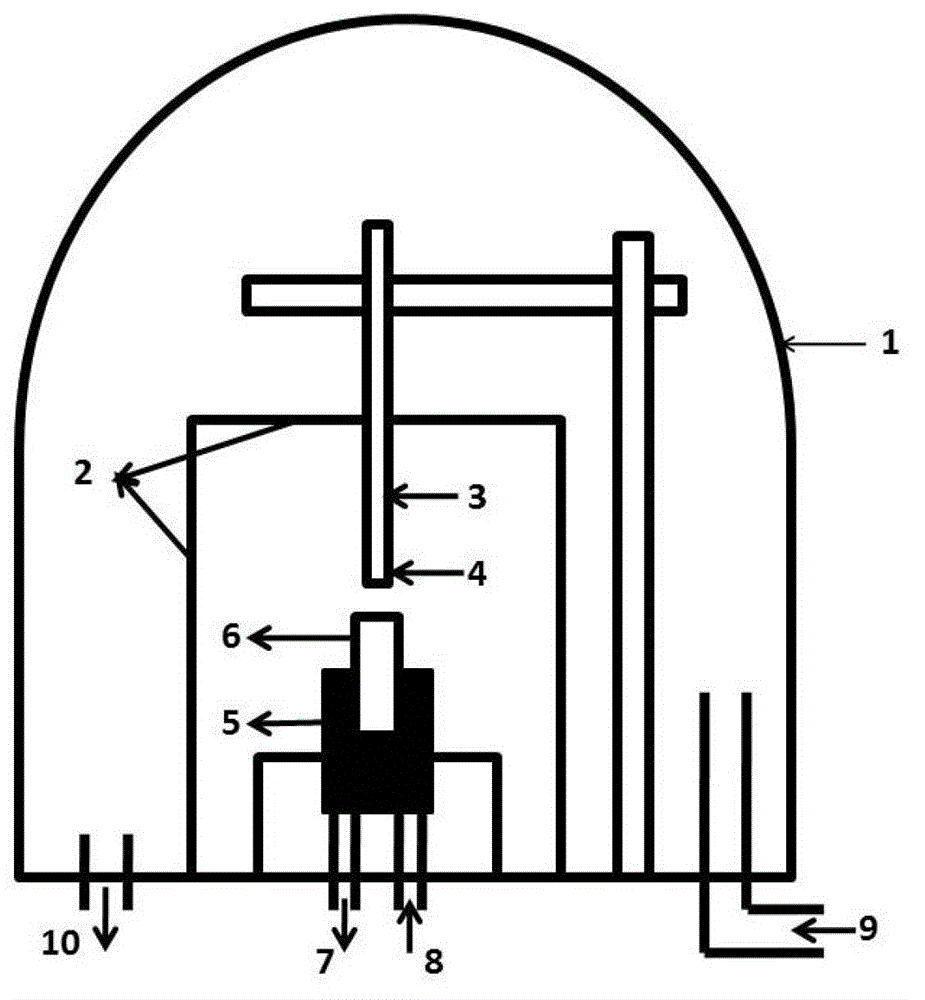

[0028] With high-purity Al and Y powder (purity 99.99%), put the pre-pressed block in the graphite crucible, put it into the copper pot anode in the reaction chamber of the DC arc discharge device, and the cathode tungsten rod is opposite to the copper pot anode Placement; first vacuumize the reaction chamber until the air pressure is lower than 1Pa, fill it with high-purity nitrogen (volume fraction greater than 99.99%), repeat vacuuming to lower than 1Pa to wash away the residual air in the vacuum system, and then fill it with high-purity nitrogen Discharge after reaching the preset pressure of 10kPa. When starting the arc, set the arc current to 150A, keep the arc stable at 15V, and the length of the positive arc column area is 0.5cm (keeping the length of the arc column area stable is beneficial to the stability of the arc characteristic curve)...

Embodiment 2

[0030] Example 2 The whole process of preparing Y-doped AlN dilute magnetic semiconductor quasi-array microtubes.

[0031] With high-purity Al and Y powder (purity 99.99%), put the pre-pressed block in the graphite crucible, put it into the copper pot anode in the reaction chamber of the DC arc discharge device, and the cathode tungsten rod is opposite to the copper pot anode Placement; first vacuumize the reaction chamber until the air pressure is lower than 1Pa, fill it with high-purity nitrogen (volume fraction greater than 99.99%), repeat vacuuming to lower than 1Pa to wash away the residual air in the vacuum system, and then fill it with high-purity nitrogen Discharge after reaching the preset pressure of 20kPa. When starting the arc, set the arc current to 100A, keep the arc stable at 20V, the length of the positive arc column area is 1cm, and cut off the power supply after about 3 minutes of discharge. After the reaction, keep the circulating water flowing continuously...

Embodiment 3

[0032] Example 3 The whole process of preparing Y-doped AlN dilute magnetic semiconductor quasi-array microtubes.

[0033] With high-purity Al and Y powder (purity 99.99%), put the pre-pressed block in the graphite crucible, put it into the copper pot anode in the reaction chamber of the DC arc discharge device, and the cathode tungsten rod is opposite to the copper pot anode Placement; first vacuumize the reaction chamber until the air pressure is lower than 1Pa, fill it with high-purity nitrogen (volume fraction greater than 99.99%), repeat vacuuming to lower than 1Pa to wash away the residual air in the vacuum system, and then fill it with high-purity nitrogen Discharge after reaching the preset pressure of 15kPa. When starting the arc, set the arc current to 120A, keep the arc stable at 25V, and the length of the positive arc column area is 1.5cm, cut off the power supply after about 5 minutes of discharge. After the reaction, keep the circulating water flowing continuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com