Preparation method of mesoporous-microporous titanium silicalite molecular sieves

A technology of silicon molecular sieve and microporous titanium, which is applied in the field of molecular sieve preparation, can solve the problems of poor catalytic oxidation activity and hydrothermal stability, etc., and achieve the effect of large specific surface area and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

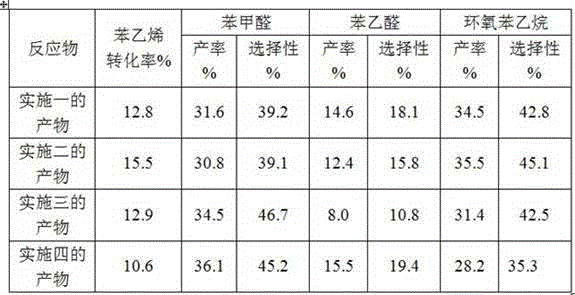

Examples

Embodiment 1

[0016] Mix tetrapropylammonium hydroxide, n-tetrabutyl titanate, ethyl orthosilicate and deionized water at a mass ratio of 1:20:8:1500, react in a constant temperature water bath cup at 35°C for a certain period of time, and then put it into a Crystallize at 140° C. for 1 hour in a kettle lined with polymethyl fluoride to obtain a clear solution of the directing agent.

[0017] Mix hexadecyltrimethylammonium bromide, deionized water, 25% ammonia water, and nanoclusters in a certain proportion, react in a constant temperature water bath cup at 30°C for 5 hours, and then put them into a kettle with a polytetrafluoroethylene liner. Crystallize in an oven at 120°C for 72h, and the product obtained is suction filtered, washed, dried at room temperature, and calcined at 500°C for 4h.

Embodiment 2

[0019] Mix tetrapropylammonium hydroxide, tetrabutyl titanate, ethyl orthosilicate and deionized water evenly at a mass ratio of 1:90:8:1500, react in a constant temperature water bath cup at 35°C for a certain period of time, and then put it into a Crystallize at 140° C. for 1 hour in a kettle lined with polymethyl fluoride to obtain a clear solution of the directing agent.

[0020] Mix hexadecyltrimethylammonium bromide, deionized water, 25% ammonia water, and nanoclusters in a certain proportion, react in a constant temperature water bath cup at 30°C for 5 hours, and then put them into a kettle with a polytetrafluoroethylene liner. Crystallize in an oven at 120°C for 72h, and the product obtained is suction filtered, washed, dried at room temperature, and calcined at 500°C for 4h.

Embodiment 3

[0022] Mix tetrapropylammonium hydroxide, n-tetrabutyl titanate, orthosilicate ethyl ester and deionized water at a mass ratio of 1:30:8:1500, and put them in a constant temperature water bath cup at 35°C for a certain period of time before putting them into a Crystallize at 140° C. for 1 hour in a kettle lined with polymethyl fluoride to obtain a clear solution of the directing agent.

[0023] Mix hexadecyltrimethylammonium bromide, deionized water, 25% ammonia water, and nanoclusters in a certain proportion, react in a constant temperature water bath cup at 30°C for 5 hours, and then put them into a kettle with a polytetrafluoroethylene liner. Crystallize in an oven at 120°C for 72h, and the product obtained is suction filtered, washed, dried at room temperature, and calcined at 500°C for 4h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com