Preparation method of conjugated diene and polar monomer segmented copolymer with low molecular weight

A technology of block copolymers and polar monomers, which is applied in the field of preparation of block copolymers of conjugated dienes and polar monomers, can solve the problems of high preparation costs and high molecular weight of copolymers, and achieve low molecular weight and high molecular weight. Narrow distribution and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention provides a kind of preparation method of low molecular weight conjugated diene and polar monomer block copolymer, comprising the following steps:

[0029] Step 1: adding the reaction monomer and the catalyst into an alkane solvent in a molar ratio of 100 to 2000:1 to obtain a solution a;

[0030] Step 2: adding the polar monomer to the solution a obtained in step 1 to obtain solution b; the molar ratio of the polar monomer to the catalyst is 10-800:1;

[0031] Step 3: adding ethanol solution to the solution b obtained in step 2 to condense a block copolymer of conjugated diene and polar monomer;

[0032] The reaction monomer is isoprene or butadiene;

[0033] The polar monomer is ε-caprolactone, butyrolactone, valerolactone or lactide;

[0034] The preparation method of the catalyst is as follows: alkoxy rare earth compound, hydrogen alkyl aluminum compound, chloride and conjugated diene are mixed and then reacted to obtain the catalyst.

[0035...

Embodiment 1

[0046] In the 10mL catalyst reaction bottle filled with nitrogen after vacuum baking, add neodymium isopropoxide (Nd), diisobutylaluminum hydride (Al), dichlorodimethylsilane (Cl) and isoprene Alkene (IP) was reacted in a constant temperature water bath at 20°C for 60 minutes to obtain a homogeneous rare earth catalyst. The molar ratio of [Nd] / [Al] / [Cl] / [IP] in this catalyst was 1 / 10 / 4 / 3 ;

[0047] Add toluene, isoprene and the above-mentioned homogeneous rare earth catalyst in turn to the 40mL ampoule bottle after vacuum drying and filling with nitrogen. The concentration of isoprene is 1mol / L, and the catalyst dosage is [IP] The / [Nd] molar ratio is 100 / 1, and the polymerization is carried out in a constant temperature water bath at 50°C. After 4 hours of polymerization, ε-caprolactone (ε-CL) monomer, ε-caprolactone and neodymium in a rare earth catalyst are added The molar ratio of the compound is [ε-CL] / [Nd]= 10 / 1, and after the polymerization reaction is carried out at 5...

Embodiment 2

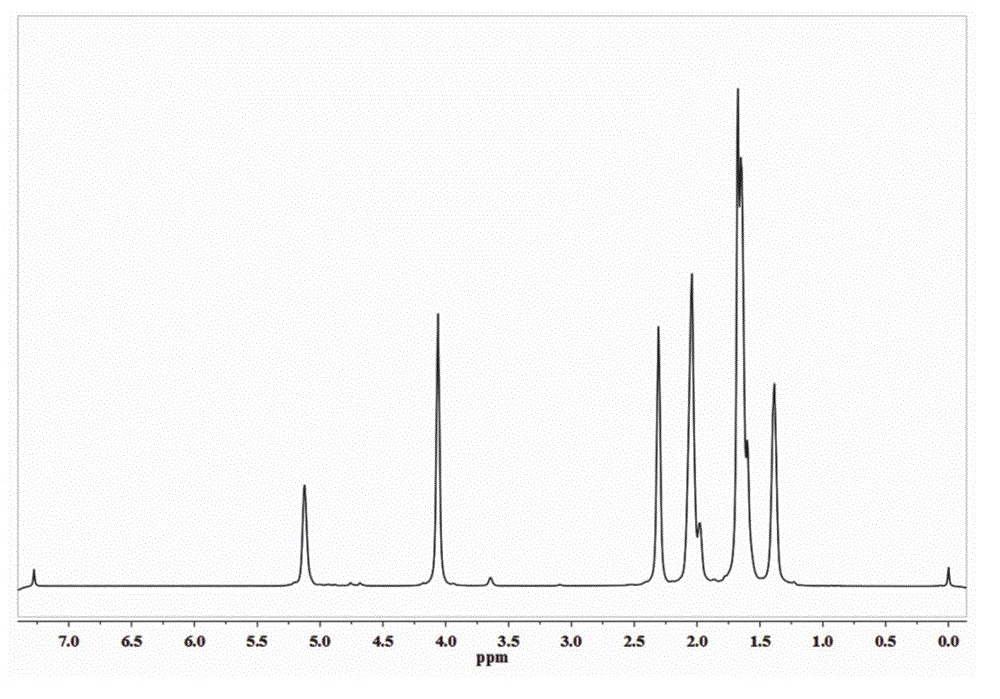

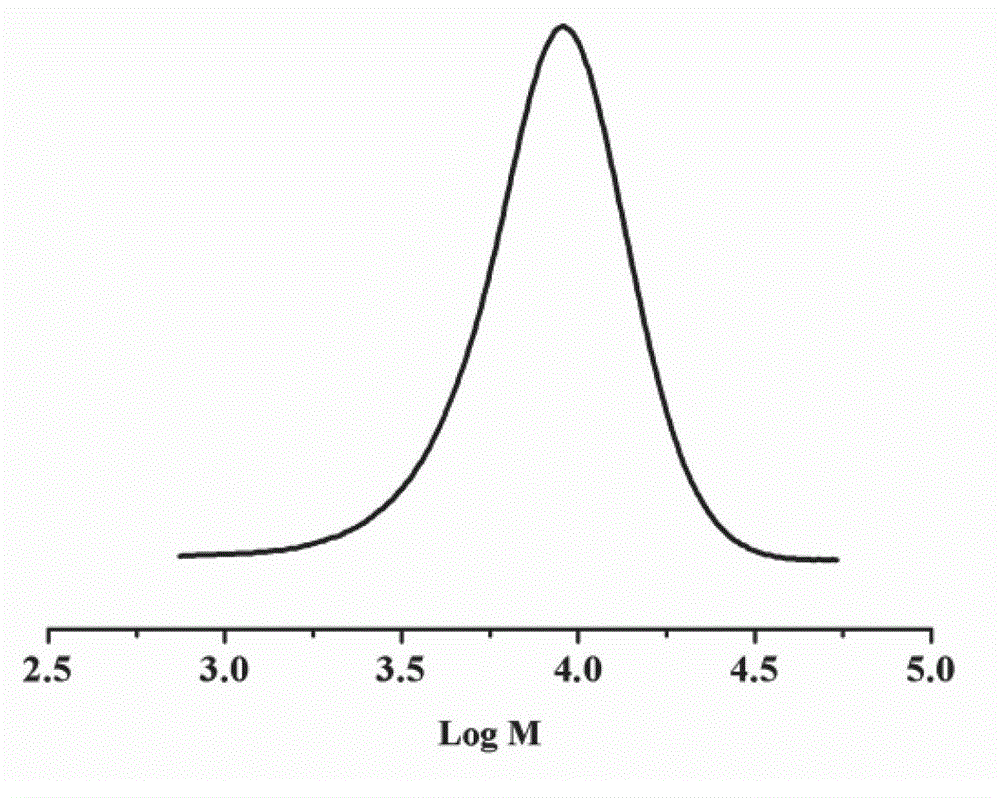

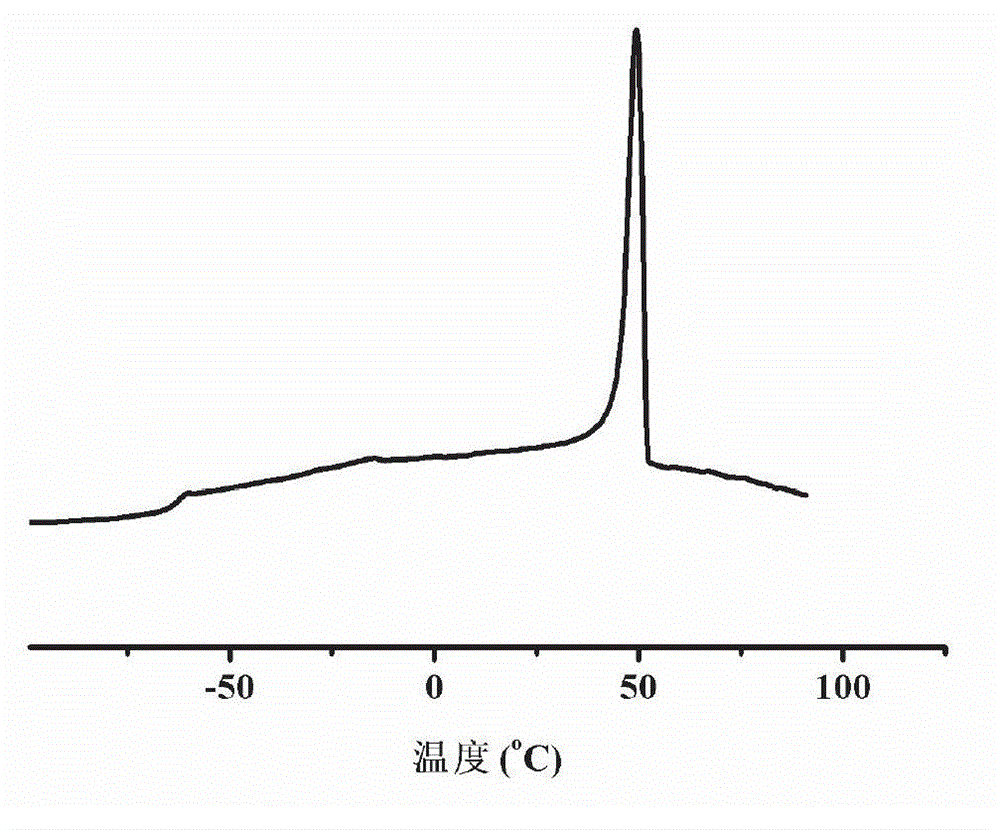

[0050] The preparation method is the same as in Example 1, except that the molar ratio of isoprene to the neodymium compound in the rare earth catalyst is [IP] / [Nd]=200 / 1, and the ratio of ε-caprolactone to the neodymium compound in the rare earth catalyst is The molar ratio is [ε-CL] / [Nd]= 50 / 1, the yield of the obtained block copolymer of conjugated diene and polar monomer is 98%, and the polyisoprene segment in the copolymer The number average molecular weight is M n = 2.16×10 3 , the molecular weight distribution is M w / M n =1.20, 1,4-structure content is 91.7%, 3,4-structure content is 8.3%, the number average molecular weight of the copolymer is M n =2.52×10 3 , the molecular weight distribution index is M w / M n =1.23. pass 1 According to H-NMR calculation, the molar ratio of polyisoprene segment to polycaprolactone segment in the copolymer is 3.8 / 1. The glass transition temperature (T) of the copolymer was measured by DSC g ) is -67.2℃, melting point (T ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com