Method for manufacturing ultrahigh-content malt syrup by double-saccharification process

A maltose syrup, ultra-high technology, applied in the field of preparation of ultra-high maltose syrup by the secondary saccharification method, can solve the problems of waste of starch raw materials, increased glucose content in maltose syrup, affecting the quality of maltose syrup, etc., and achieve the effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

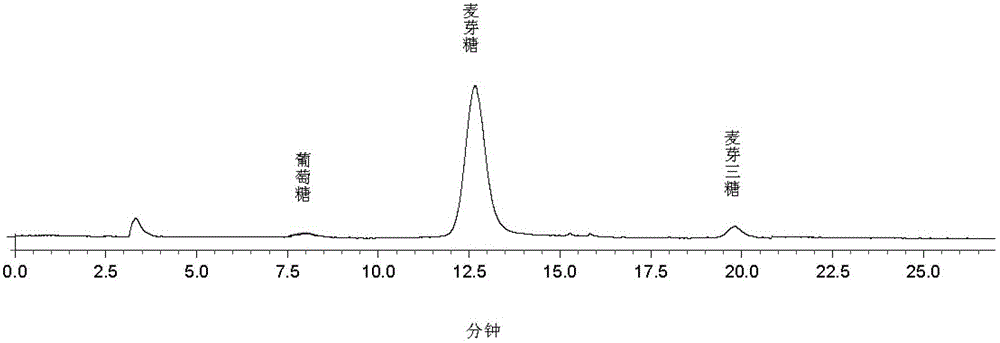

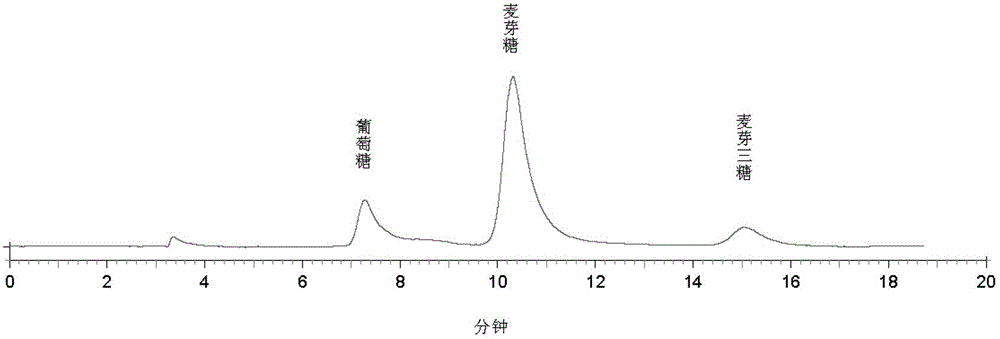

Image

Examples

Embodiment Construction

[0024] The technical scheme of the present invention is further described by the following examples. The following experiments and examples belong to the main content of the present invention, and some of the routine experimental methods for those skilled in the art do not appear in this description.

[0025] 1. liquefied starch using α-starch

[0026] Mix the starch into a 30% starch water slurry, add α-amylase at 10U / g starch to liquefy the starch, control the DE value of liquefaction at 10-12%, then adjust the pH to 5.2-5.5 with hydrochloric acid, and then immediately raise the temperature to Inactivate the α-amylase activity by inactivating the α-amylase activity by incubating at a temperature above 100°C for 10 minutes to obtain a dextrin.

[0027] 2. saccharification

[0028] Add pullulanase to the dextrin obtained by liquefaction in step 1, add pullulanase at 0.2mL / kg starch, incubate at 60°C, pH5.2~5.4 for 2 hours, then add β-amylase at 250U / g starch, continue Keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com