Palladium-copper-aluminum trioxide catalysis separation composite membrane, preparation method and application

An aluminum oxide and composite membrane technology, which is applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as time-consuming and complex process operations, and save time in the preparation process. , The effect of using the equipment is simple and the steps are few

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of a palladium-copper-aluminum oxide catalytic separation composite membrane, specifically comprising the steps of:

[0040] (1) Put the 90mm×60mm×250μm porous through-hole anodized aluminum oxide film into a 500mL beaker, add 420mL of pure water, clean it with ultrasonic waves for 30min, take out the porous through-hole anodized aluminum oxide film, and dry it in an oven at 100°C 0.5h, burn in a high-temperature furnace at 800°C for 5h, take out the porous through-hole anodic aluminum oxide film and cool to room temperature;

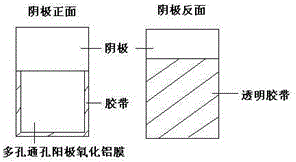

[0041] (2) Use transparent tape to paste the above-mentioned porous through-hole anodized aluminum film to be plated on the electrolytic nickel plate of 150mm×60mm×2mm, and paste the transparent tape on the reverse side of the electrolytic nickel plate. The specific method of pasting like figure 1 As shown, that is, firstly, the above-mentioned porous through-hole anodized aluminum film to be plated is placed on one end of a 1...

Embodiment 2

[0052] A preparation method of a palladium-copper-aluminum oxide catalytic separation composite membrane, specifically comprising the steps of:

[0053] (1) Put a 90mm×60mm×250μm porous through-hole anodized aluminum oxide film into a 500mL beaker, add 420mL of pure water, clean it with ultrasonic waves for 5min, take out the porous through-hole anodized aluminum oxide film, and dry it in an oven at 50°C 5h, burn in a high-temperature furnace at 1100°C for 0.5h, take out the aluminum oxide film and cool to room temperature;

[0054] (2), the above-mentioned processed porous through-hole anodic aluminum oxide film to be plated is pasted on a steel plate of 150 mm * 60 mm * 2 mm with double-sided adhesive tape, and a scotch tape is pasted on the reverse side of the steel plate, specifically the same as in Example 1;

[0055] (3) Add 10g of palladium acetate, 30g of copper chloride, 20g of copper nitrate, 20g of acetic acid, 30g of potassium chloride into a 2L beaker, and dissolv...

Embodiment 3

[0065] A preparation method of a palladium-copper-aluminum oxide catalytic separation composite membrane, specifically comprising the steps of:

[0066] (1) Put a 90mm×60mm×250μm porous through-hole anodized aluminum oxide film into a 500mL beaker, add 420mL of pure water, clean it with ultrasonic waves for 17min, take out the porous through-hole anodized aluminum oxide film, and dry it in an oven at 85°C 2h, burn in a high-temperature furnace at 900°C for 3h, take out the porous through-hole anodized aluminum film and cool it to room temperature;

[0067] (2), the above-mentioned treated porous through-hole anodic aluminum oxide film to be plated is pasted on a steel plate of 150mm * 60mm * 2mm with scotch tape, and the scotch tape is pasted on the back of the steel plate, specifically the same as in Example 1;

[0068] (3) Add 2 g of palladium chloride, 2 g of palladium acetate, 0.8 g of copper nitrate, 5 g of tartaric acid, and 15 g of ammonium chloride into a 2L beaker, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com