Preparation method of thiol-modified graphene

A sulfhydryl modification, graphene technology, applied in the directions of graphene, nano-carbon, etc., can solve the problems of cumbersome processing, nano-particle agglomeration, difficulty in obtaining graphene, etc., and achieves mild and environmentally friendly reaction conditions, simple and fast processing methods, and cheap raw materials. easy-to-get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Disperse 0.1g of graphite oxide into 200mL of DMF, then pour the dispersion into a 500mL three-necked flask, and add 0.1g of 2-mercaptoethylamine. Under mechanical stirring, react at 60°C for 10h. After the reaction was completed, it was filtered with suction and washed with DMF several times. A mercapto-modified graphite oxide was obtained. Disperse 0.1g of mercapto-modified graphite oxide into 200 L of DMF, pour the dispersion into a 500mL three-neck flask, add 0.2g of hydrazine hydrate, and react at 90°C for 24h under mechanical stirring. After the reaction was completed, it was filtered with suction and washed with DMF several times. After vacuum drying, thiol-modified graphene was obtained.

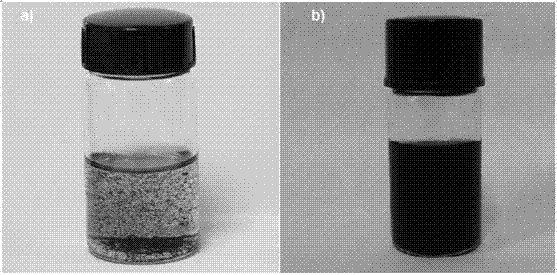

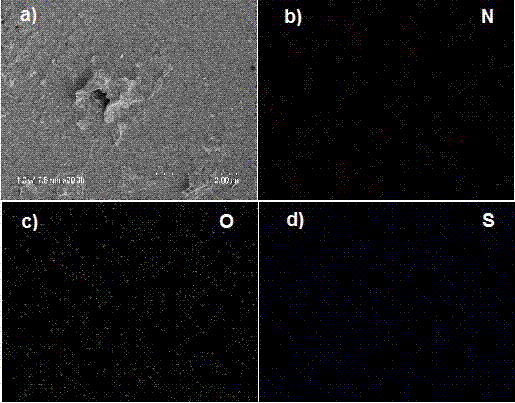

[0024] Take a sample and test the product. figure 1 It is a physical photo of graphene and mercaptographene dispersed in DMF; figure 2 It is the SEM photo and EDS surface scanning image of thiol-modified graphene; from figure 1 It can be seen that the thiol-modified gra...

Embodiment 2

[0026] Preparation method is with embodiment 1, uses HS (CH respectively 2 ) n NH 2 (n takes an integer between 3-18) to replace 2-mercaptoethylamine to obtain the corresponding mercapto-modified graphene product. For product testing, HS(CH 2 ) n NH 2 Successfully modified to the surface of graphene, thiol-modified graphene has good dispersion in DMF.

Embodiment 3

[0028] Disperse 0.1g of graphite oxide into 200mL of a 1:1 mixed solvent of water and ethanol, then pour the dispersion into a 500mL three-necked flask, and add 0.4g of 2-mercaptoethylamine. Under mechanical stirring, the reaction was carried out at room temperature for 24 hours. After the reaction was completed, it was filtered with suction and washed with water several times. A mercapto-modified graphite oxide was obtained. Disperse 0.2g of mercapto-modified graphite oxide into 200mL of water, pour the dispersion into a 500mL three-necked flask, add 0.02g of hydrazine hydrate, and react at 60°C for 36h under mechanical stirring. After the reaction was completed, it was filtered with suction and washed with water several times. The thiol-modified graphene was obtained after freeze-drying.

[0029] For product testing, 2-mercaptoethylamine was successfully modified on the surface of graphene, and mercapto-modified graphene has good dispersion in DMF.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com