Method for preparing large-size zinc-oxide based target by casting through novel low-toxicity gel

A zinc oxide-based, large-size technology is applied in the field of preparing large-size zinc oxide-based targets by new low-toxic gel casting, which can solve the problems of difficult molding, high production costs, and poor target uniformity, and achieve high quality, The effect of low equipment requirements and large target size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] a) Preparation of the premix solution, dissolving methacrylamide, N,N′-methylenebisacrylamide, and ammonium polyacrylate in water (preferably deionized water), stirring evenly to obtain a clear transparent liquid. The weight percentage of methacrylamide in the premix can be 1-20 wt%, preferably 10-20 wt%; the weight percentage of N,N'-methylenebisacrylamide can be 0.1-2 wt%, preferably 0.5 ~1.5wt%; the weight percentage of ammonium polyacrylate can be 0.1~10wt%, preferably 1~8wt%. The temperature of the premixed solution may be 5-60°C.

[0029] b) Weighing the required inorganic powder raw material according to the chemical composition of the desired target material, preferably high-purity (for example, purity greater than N) powder raw material, the powder raw material includes high-purity zinc oxide and at least one additional component, Additional components include aluminum oxide, gallium oxide, indium oxide, silicon oxide, aluminum powder, and / or indium nitrate. ...

Embodiment 1

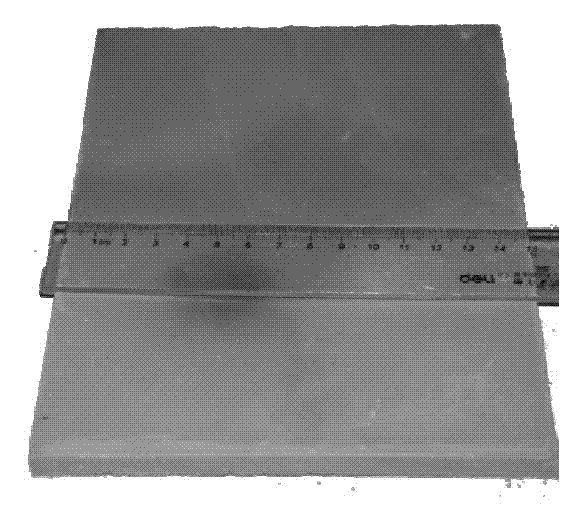

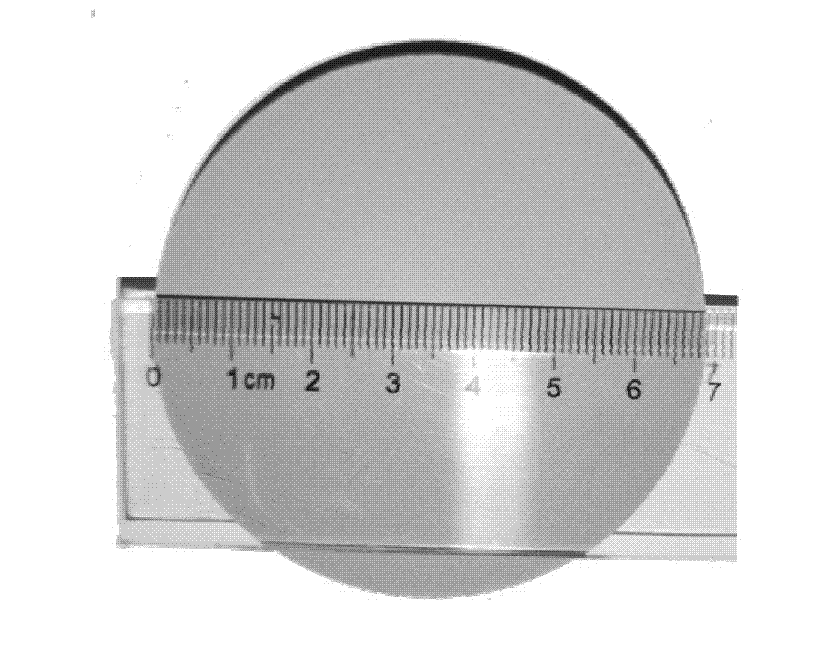

[0039] Take 130g of deionized water, add 25g of methacrylamide, 13g of ammonium polyacrylate and 1.3g of N,N'-methylenebisacrylamide, and stir with high-speed magnetic force to obtain a uniform light yellow transparent solution, that is, the premix. Add to the ball mill jar. Weigh 980g of zinc oxide powder and 20g of alumina powder, mix them, add them to a ball mill tank in batches, and use alumina spheres to mill for 36 hours to fully infiltrate the powder with water to obtain a uniform and stable yellow slurry. Add 1ml of tetramethylethylenediamine (as a catalyst) and 3ml of ammonium persulfate (as an initiator) to the slurry, mix well and pour it into the mold quickly, let it stand to solidify, demould, and dry. The dried green body is degummed under a certain heating curve (the total degumming time is 21.5h, divided into 8 stages, and the maximum temperature is 900°C): the temperature is raised to 100°C at 2°C / min (heating rate), and the temperature is kept 1h, then heat ...

Embodiment 2

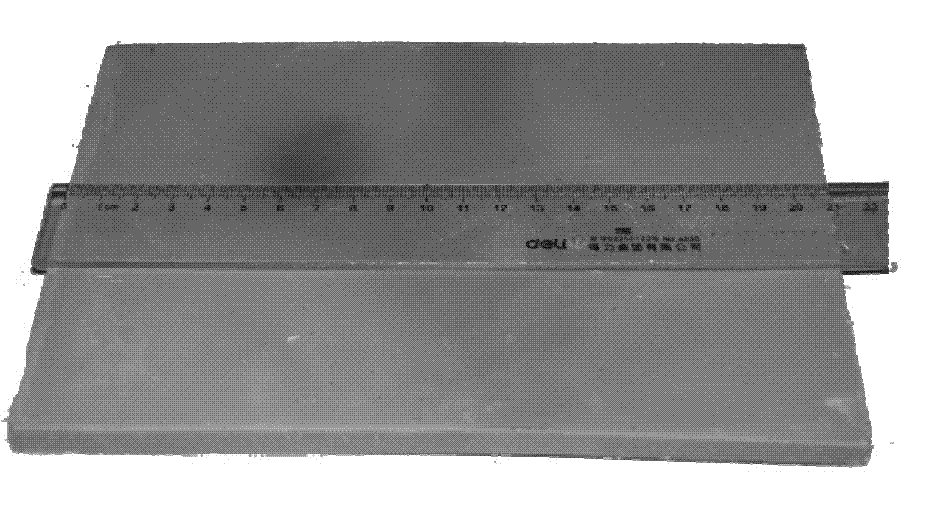

[0041] Take 390g of deionized water, add 75g of methacrylamide, 39g of ammonium polyacrylate solution, 1.3g of N,N'-methylenebisacrylamide, 4g of tetramethylethylenediamine and 9g of polyethylene glycol, and stir with a high-speed magnetic force , to obtain a uniform light yellow transparent solution. Weigh 3328g of zinc oxide and 72g of alumina powder, and ball mill for 48 hours to obtain a stable slurry. Ammonium persulfate is added to the slurry, stirred quickly and evenly, poured into a mold, solidified and dried to obtain a green body. The dried green body is degummed under a certain heating curve (the total degumming time is 21.5h, divided into 8 stages, and the maximum temperature is 900°C): the temperature is raised to 100°C at 2°C / min (heating rate), and the temperature is kept 1h, then heat up to 500°C at 1°C / min, hold for 1h, then heat up to 600°C at 1°C / min, hold for 1h, heat up to 900°C at 1°C / min, hold for 2h, and finally cool down at 1°C / min After reaching 750...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com