Dry heat treatment stabilizer for human blood coagulation factor VIII and application thereof

A technology of human coagulation factor and dry heat treatment, which is applied in the direction of coagulation/fibrinolytic factor, enzyme stabilization, factor VII, etc., can solve the problems of low activity recovery rate of human coagulation factor VIII, low application value, and low cost, and achieve good clinical results Application prospects, low cost, and few types of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 Preparation of human coagulation factor VIII preparation of the present invention

[0023] 1. Preparation method

[0024] Ⅰ. Separation and purification

[0025] (1) Using fresh frozen plasma as raw material, melt the plasma and centrifuge to prepare cryoprecipitate, dissolve the cryoprecipitate in 0.02M Tris buffer, precipitate with 30% polyethylene glycol, absorb with aluminum hydroxide and centrifuge to obtain the supernatant;

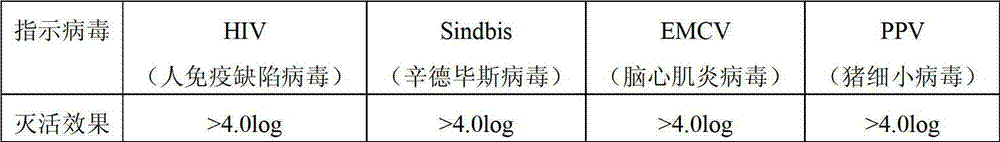

[0026] (2) After the supernatants were combined and clarified, Tween-80 and tributyl phosphate were added to make the final concentrations 1% and 0.3%, respectively, and treated at 25°C±1°C for 6 hours to complete the first virus inactivation (that is, SD virus inactivation);

[0027] (3) Use Toyopearl DEAE 650M as the gel for further purification by ion exchange chromatography, the buffer is 0.001M sodium citrate buffer, by changing the sodium chloride ionic strength of the chromatography buffer , and the eluate containing hu...

Embodiment 2

[0031] Embodiment 2 Preparation of human coagulation factor VIII preparation of the present invention

[0032] 1. Preparation method

[0033] Ⅰ. Separation and purification

[0034] (1) Using fresh frozen plasma as raw material, melt the plasma and centrifuge to prepare cryoprecipitate, dissolve the cryoprecipitate in 0.02M Tris buffer, precipitate with 30% polyethylene glycol, absorb with aluminum hydroxide and centrifuge to obtain the supernatant;

[0035] (2) After the supernatants were combined and clarified, Tween-80 and tributyl phosphate were added to make the final concentrations 1% and 0.3%, respectively, and treated at 25°C±1°C for 6 hours to complete the first virus inactivation (that is, SD virus inactivation);

[0036] (3) Using Toyopearl DEAE 650M as the gel as the filler for further purification by ion exchange chromatography, the buffer is 0.05M sodium citrate buffer, and collected by changing the sodium chloride ionic strength of the chromatography buffer E...

Embodiment 3

[0040] Embodiment 3 Preparation of human coagulation factor VIII preparation of the present invention

[0041] 1. Preparation method

[0042] Ⅰ. Separation and purification

[0043] (1) Using fresh frozen plasma as raw material, melt the plasma and centrifuge to prepare cryoprecipitate, dissolve the cryoprecipitate in 0.02M Tris buffer, precipitate with 30% polyethylene glycol, absorb with aluminum hydroxide and centrifuge to obtain the supernatant;

[0044] (2) After the supernatants were combined and clarified, Tween-80 and tributyl phosphate were added to make the final concentrations 1% and 0.3%, respectively, and treated at 25°C±1°C for 6 hours to complete the first virus inactivation (that is, SD virus inactivation);

[0045] (3) Use Toyopearl DEAE 650M as the gel as the filler for further purification by ion exchange chromatography, the buffer is 0.02M sodium citrate buffer, and the sodium chloride ionic strength of the chromatography buffer is changed to collect and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com