Production process of rubber vulcanization accelerator mbts

A production process and rubber vulcanization technology, which is applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., and can solve problems such as increasing production costs, difficult wastewater treatment, and inability to continue to apply them. , to achieve the effect of improving environmental protection and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

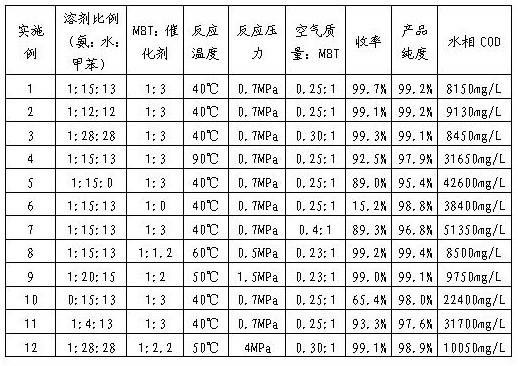

Examples

Embodiment 1

[0031] Embodiment 1: a kind of production technology of rubber vulcanization accelerator MBTS comprises the following steps:

[0032] (1) At 35°C, mix MBT with a mass ratio of 1:5 and the solvent for 0.6h under stirring. The solvent is a mixture of ammonia, water and toluene. In the solvent, ammonia:water:toluene=1:15: 13. After the mixing is completed, it is the raw material liquid;

[0033](2) After putting the raw material liquid into the autoclave, add a macroporous anion exchange resin catalyst with a mass three times the mass of MBT. After starting the stirring, introduce air to a pressure of 0.7Mpa to start the oxidation reaction. During the process, the reaction temperature was controlled at 40°C. When the total mass of the air introduced reached 0.25 times the mass of the input MBT, the air was stopped, and the reaction was completed after continuing to stir for 2 hours.

[0034] (3) After the pressure in the kettle is released, the material is passed through a coar...

Embodiment 5

[0041] In Example 5, since there is no toluene component in the solvent, and the ammonia content in the system is relatively high due to the ratio problem, the raw material MBT is oxidized to other by-products during the oxidation process, which reduces the reaction yield. At the same time, this technology controls the overall oxygen intake in the oxidation process, and the deep oxidation of the raw material MBT consumes excess oxygen, so that not only peroxidation by-products are produced during the reaction process, but also the raw material MBT is unreacted. In addition, since there is no toluene solvent in the system, the oil-soluble impurities in MBT cannot be separated from the product, resulting in a decrease in the purity of MBTS. After detection and analysis, the yield of the product MBTS was only 89.0%, and the purity was 95.4%. At this time, the water phase is red, and the COD of the wastewater is 42600mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com