Preparation method of colorful polyurethane emulsion

A technology of polyurethane emulsion and water-based polyurethane, which is applied in the field of preparation of colored polyurethane emulsion, and can solve problems such as thermodynamic incompatibility, inconvenient production, and poor compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0009] The preparation method of this colored polyurethane emulsion comprises the following steps:

[0010] (1) Prepare prepolymer by reacting isocyanate, polyether polyol and polyester polyol;

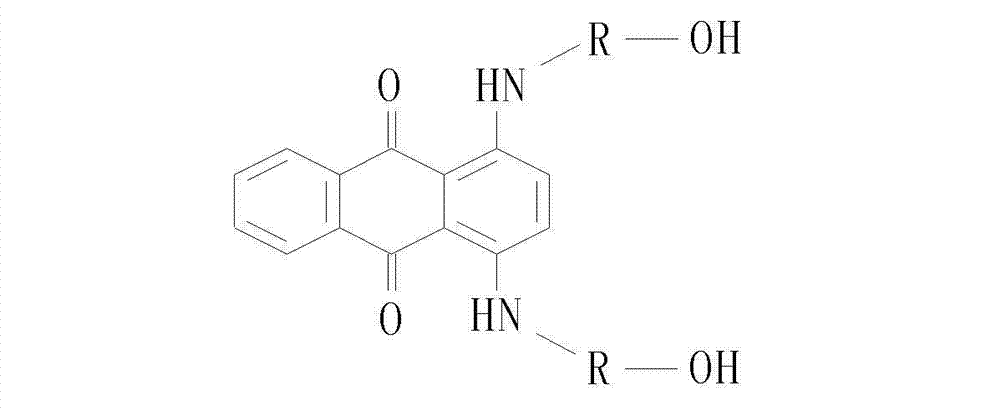

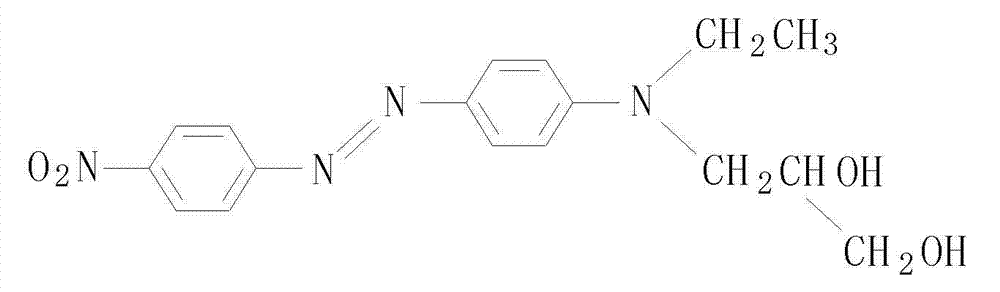

[0011] (2) Carry out chain extension reaction with the prepolymer prepared in step (1) with colored small molecule chain extender, common small molecule chain extender and hydrophilic chain extender;

[0012] (3) Neutralize with a salt-forming agent, add water to disperse and emulsify, and distill off the organic solvent under reduced pressure to obtain a colored water-based polyurethane emulsion.

[0013] In the preparation method of this colored polyurethane emulsion, the isocyanate described in step (1) can be isophorone diisocyanate, hydrogenated diphenylmethane diisocyanate, dimethylene phenyl diisocyanate, tetramethylcyclo One or more of hexane diisocyanate, 1,6-hexamethylene diisocyanate, the polyether polyol can be polyethylene glycol, polyoxypropylene glycol, polytetrahydrof...

Embodiment 1

[0042] (a) Preparation of blue small molecule chain extender:

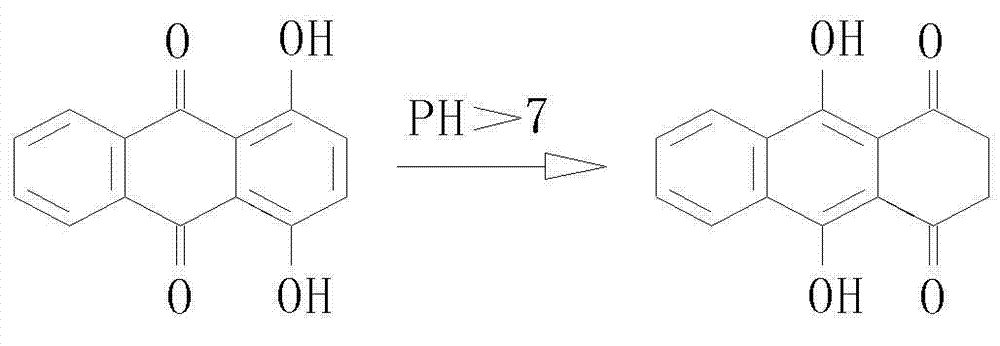

[0043] First, add 16g of 1,4-dihydroxyanthraquinone, 30g of potassium carbonate, and 200ml of deionized water into a 1000ml three-necked flask. After heating to boiling, add 40g of sodium hyposulfite, and then add 10g of sodium hyposulfite after 15 minutes to ensure complete reduction. After cooling, filter with suction to obtain 6.9 g of brown needle-like substance.

[0044] Weigh 9.6 g of the synthesized brown substance, add 20 equivalents of isopropanolamine, stir and react at 50° C. for 1 hour under the protection of nitrogen, and then pass through air to oxidize and continue the reaction for 40 minutes. After the reaction, the temperature was lowered to 15°C, acetonitrile was added for precipitation, and 12 g of the desired blue small molecule chain extender 1,4-bis(2-methyl-3-hydroxyethylamino)anthraquinone was obtained by suction filtration.

[0045] (b) Preparation of prepolymer

[0046] Add 87.5g of MDI...

Embodiment 2

[0052] (a) Preparation of blue small molecule chain extender:

[0053] First, add 8g of 1,4-dihydroxyanthraquinone, 18g of potassium carbonate, and 200ml of deionized water into a 1000ml three-necked flask. After heating to boiling, add 17g of sodium hyposulfite, and then add 5g of sodium hyposulfite after 15 minutes to ensure complete reduction. After cooling, filter with suction to obtain 6.9 g of brown needle-like substance.

[0054] Weigh 6.5 g of the synthesized brown substance, add 15 equivalents of 2-amino-2-methyl-1-propanol, stir and react at 50° C. for 1 hour under the protection of nitrogen, and then continue the reaction for 40 minutes by passing through air for oxidation. After the reaction, the temperature was lowered to 15°C, acetonitrile was added for precipitation, and 8 g of the desired blue small molecule chain extender 1,4-bis(1,1-dimethyl-2-hydroxyethylamino)anthraquinone was obtained by suction filtration.

[0055] (b) Preparation of prepolymer

[0056]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com