Dual luminous water-based polyurethane paint based on chromophores in hydroxyl-terminated polylactic acid and preparation method thereof

A water-based polyurethane and hydroxypolylactic acid technology, applied in the preparation of luminescent materials, luminescent coatings, organic compounds, etc., can solve the problems of small molecule migration, poor luminescence stability and durability, and increased cost, and reduce the use and distribution of organic solvents. Wide and adjustable effect with long-lasting luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

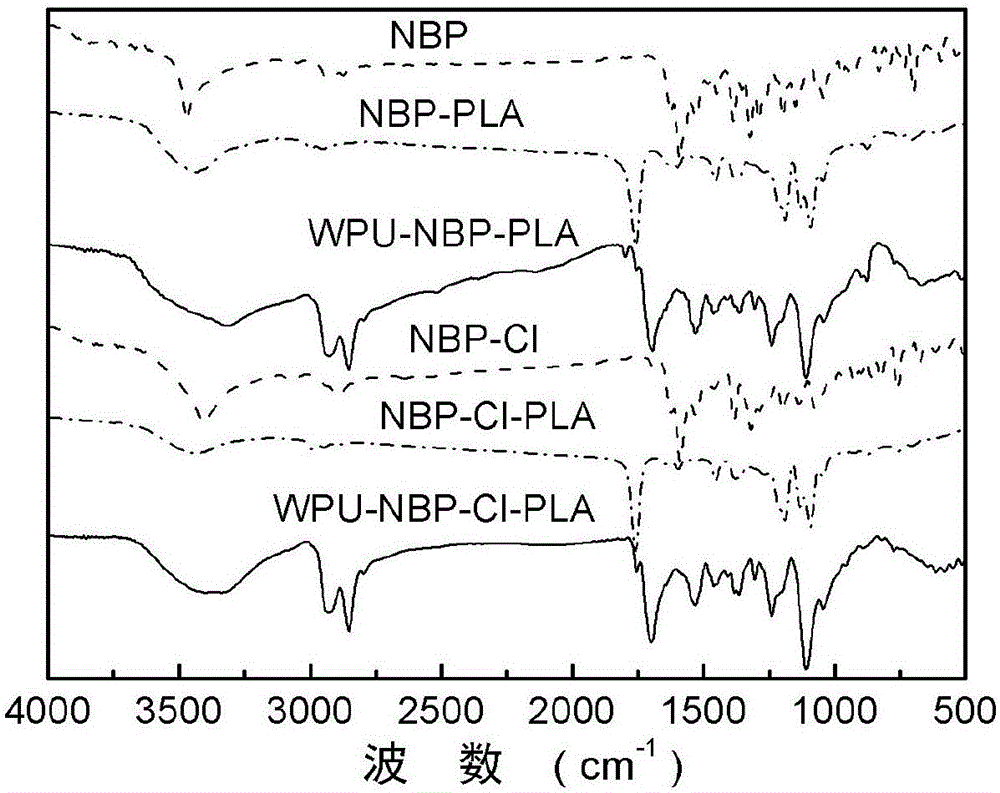

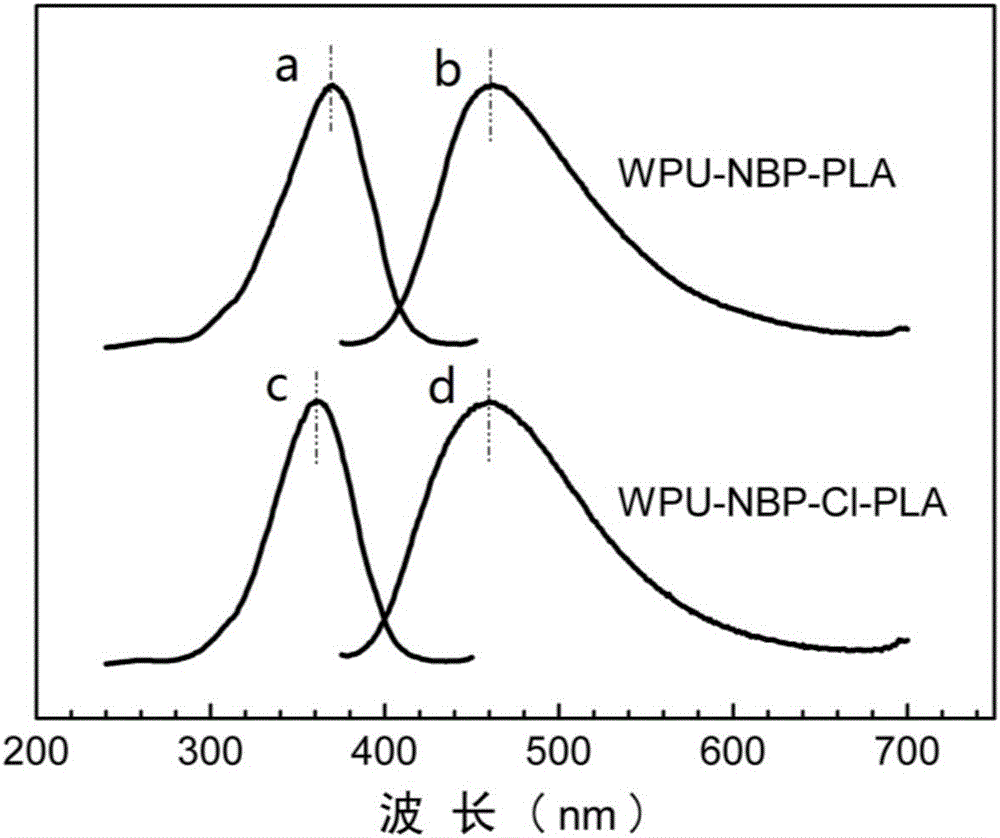

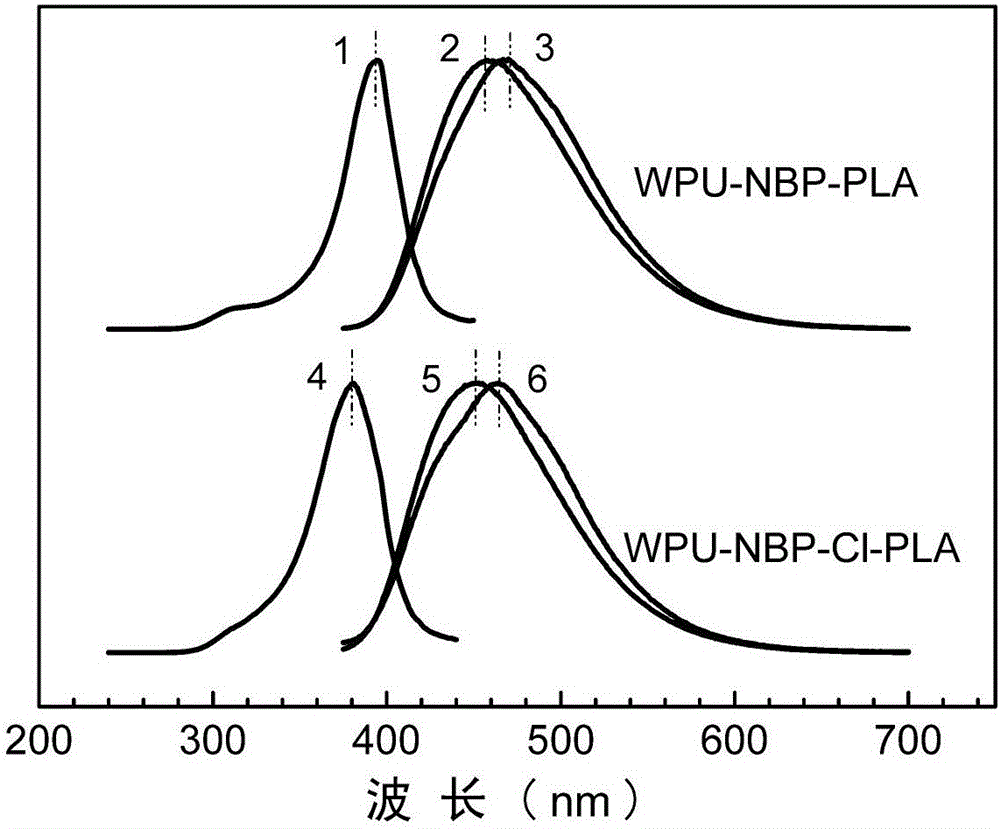

Method used

Image

Examples

Embodiment 1

[0039] 1. Add 4g of 4-fluorobenzophenone, 10.5g of 2-methylaminoethanol and 4.14g of potassium carbonate into a 250mL three-necked flask, stir with a magnetic stirrer and heat up to 130°C, react for 12 hours, and cool down to end the reaction . Add 100 mL of deionized water into the flask, stir at room temperature for 1 hour, a solid precipitates, and filter under reduced pressure to obtain a light yellow solid. The product was dried in a vacuum oven to obtain 3.22 g of a pale yellow product (4-((2-hydroxyethyl)(methyl)amino)phenyl)benzophenone (NBP), with a yield of 0.63. The product is soluble in dichloromethane, ethyl acetate and other solvents.

[0040] 2. In N 2 Under protection, add 0.3g initiator (4-((2-hydroxyethyl)(methyl)amino)phenyl)benzophenone (NBP), 29.7g D successively to the reaction flask with magnetic stirring bar, L-lactide, 0.6g n-hexane solution of stannous octoate. The reaction vial was sealed and immersed in an oil bath at 130°C for reaction. When t...

Embodiment 2

[0048] 1. Add 5.4g of 4,4-dichlorobenzophenone, 11.25g of 2-methylaminoethanol and 4.44g of potassium carbonate into a 250mL three-neck flask, stir with a magnetic stirrer, heat up to 130°C, and react for 12 hours , cooling down to end the reaction. After cooling down to room temperature, 120 mL of deionized water was added and stirred at room temperature for 1 hour. After an oily precipitate appeared, the water layer was separated from the oily precipitate to obtain a brownish-yellow oil. Use ethyl acetate:petroleum ether at a volume ratio of 2:1 as the eluent, separate and purify with a chromatographic column (200-300 mesh silica gel) to obtain a light yellow solution; use vacuum distillation to remove the solvent to obtain a yellow powder Finally, it was dried in a vacuum oven to obtain 3.40 g of yellow product (4-chlorophenyl) (4-((2-hydroxyethyl)(methyl)amino)benzophenone (NBP-Cl ), the productive rate is 0.55. This product is soluble in solvents such as dichloromethane,...

Embodiment 3

[0057] 1. Add 6.0g of 1-(4-chlorophenyl)-3-phenylpropane-1,3-dione, 14.47g of 2-methylaminoethanol and 6.2g of potassium carbonate into a 250mL three-necked flask and stir with a magnetic force Stir in a container, and heat up to 130° C., react for 12 hours, and cool down to complete the reaction. Add 150 mL of deionized water into the flask, stir at room temperature for 1 hour, and a solid precipitates, which is filtered under reduced pressure to obtain a light yellow solid. The product was placed in a vacuum oven and dried to obtain 4.13g of light yellow product 1-(4-((2-hydroxyethyl)(methyl)amino)phenyl)-3-phenylpropane-1,3-dione ( HMP), the yield was 0.60. The product is soluble in dichloromethane, ethyl acetate and other solvents.

[0058] 2. In N 2Under protection, add 0.9g initiator 1-(4-((2-hydroxyethyl)(methyl)amino)phenyl)-3-phenylpropane-1,3 - Diketone, 17.1g D, L-lactide, 0.36g n-hexane solution of stannous octoate, seal the reaction bottle and immerse it in an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com