A kind of preparation method of white fluorescent waterborne polyurethane coating

A water-based polyurethane, blue fluorescent technology, applied in polyurea/polyurethane coatings, luminescent coatings, coatings, etc., can solve the problem of uneven fluorescence chromaticity, incomplete chromophore chromatography, material stability, and insufficient processing cost. and other problems, to achieve the effect of high color fastness, good fluorescence persistence, and not easy to migrate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

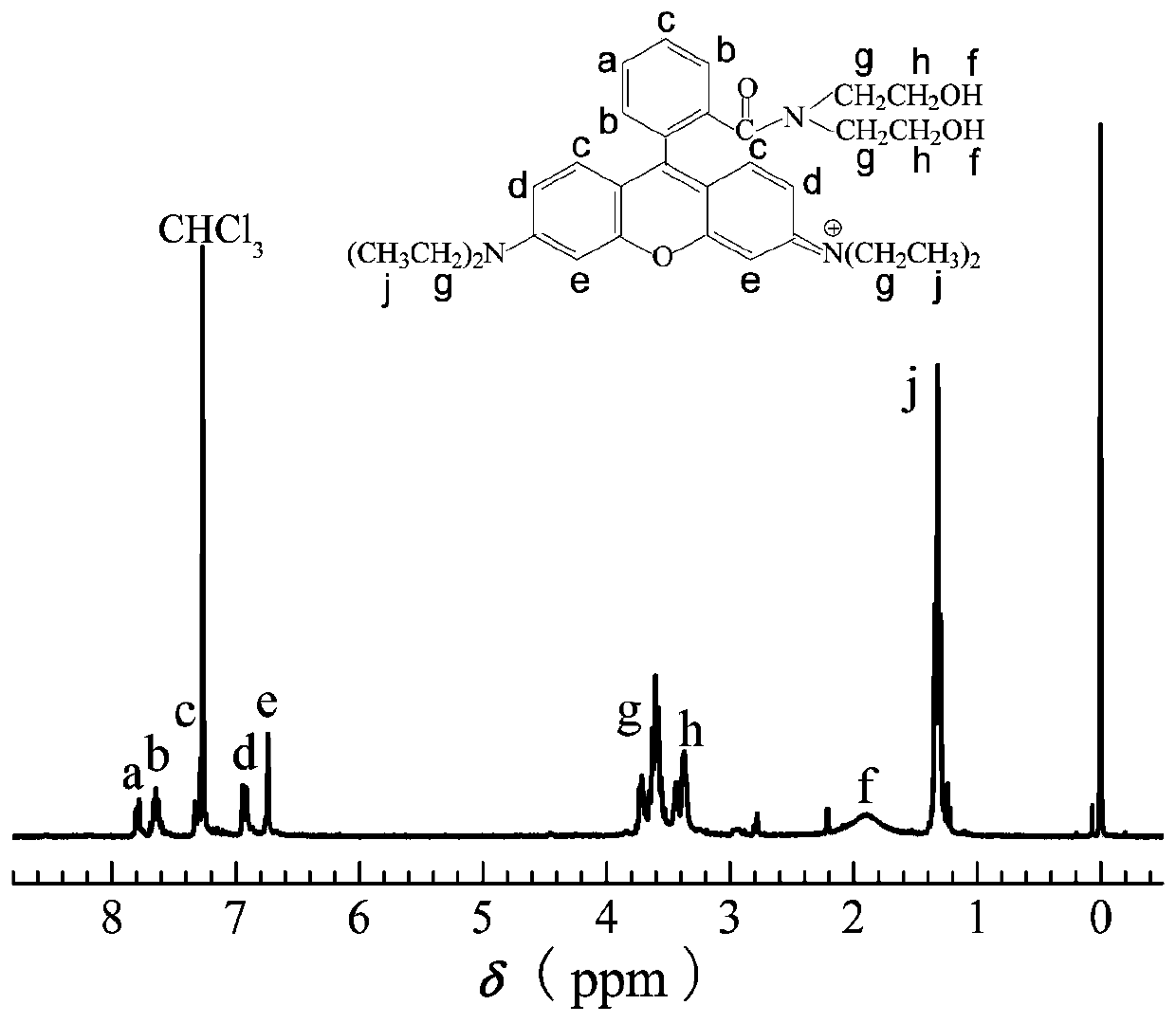

[0037] Add 1.48 g of rhodamine B and 30 ml of dichloromethane into a three-necked flask, stir until rhodamine B is completely dissolved, add 0.42 g of diethanolamine, 0.35 g of triethylamine, and 1.31 g of HBTU; react at room temperature under stirring with a magnetic stirrer After 15 hours, pour into 70 ml of dichloromethane to dilute, and wash with 50 ml of 1M sodium chloride aqueous solution 3 times; after drying the organic phase with anhydrous magnesium sulfate, the dichloromethane is removed under vacuum; the crude product is reconstituted with ethanol After crystallization, it is placed in a vacuum oven and dried to a constant weight to obtain a red fluorescent diol RDB-OH;

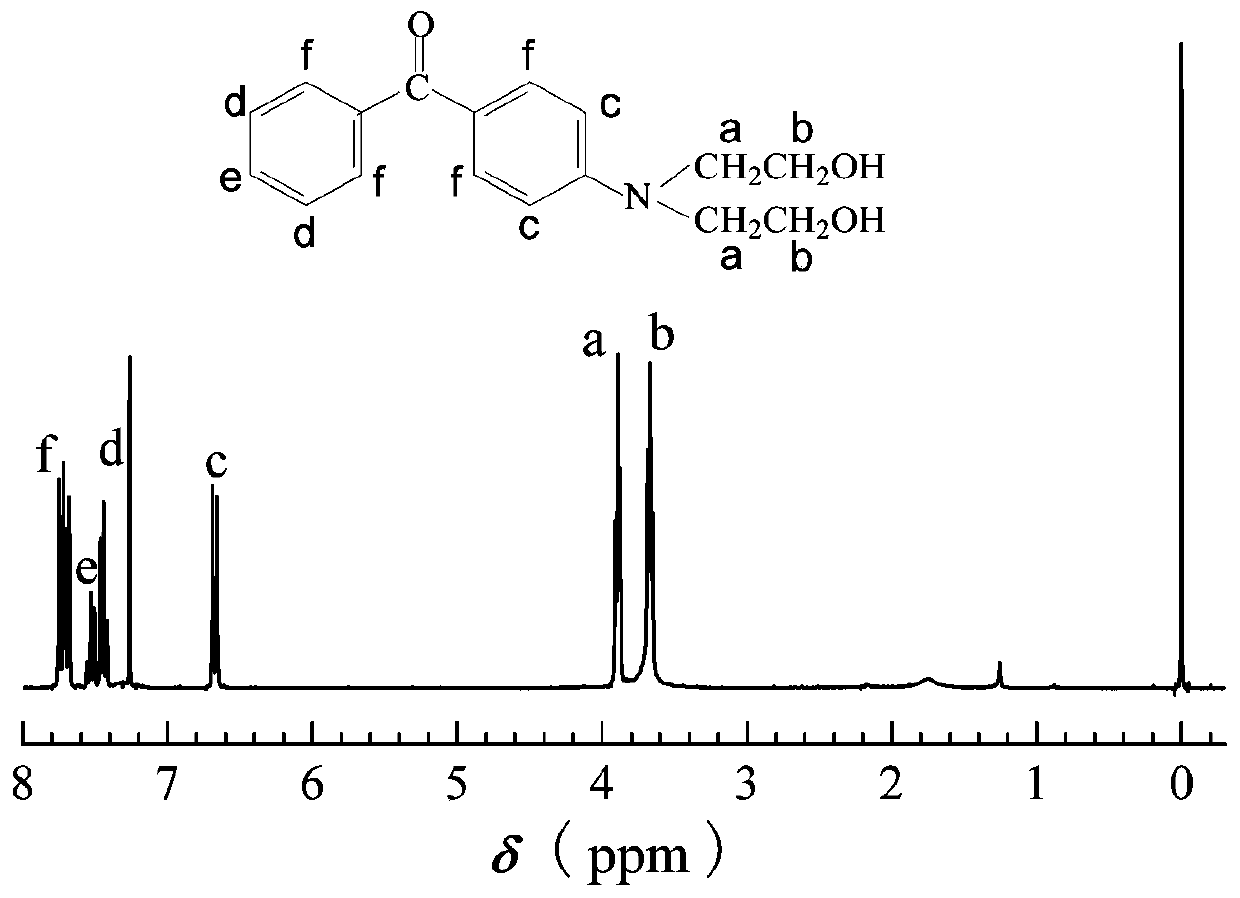

[0038] Add 2.16 g of 4-fluorobenzophenone, 7.1 g of diethanolamine and 1.12 g of potassium hydroxide into a three-necked flask, stir with a magnetic stirrer, and raise the temperature to 100°C. After 18 hours of reaction, the reaction is finished; after cooling to room temperature, Add 100 ml of disti...

Embodiment 2

[0053] Add 4.8 g of rhodamine B and 50 ml of dichloromethane into a three-necked flask, stir until rhodamine B is completely dissolved, add 1.8 g of diethanolamine, 1.3 g of triethylamine, and 4 g of HBTU; react at room temperature under stirring with a magnetic stirrer After 18 hours, pour into 100 ml of dichloromethane to dilute, and wash 4 times with 50 ml of 1M sodium chloride aqueous solution; after drying the organic phase with anhydrous magnesium sulfate, remove the dichloromethane under vacuum; the crude product is reconstituted with ethanol After crystallization, it is placed in a vacuum oven and dried to a constant weight to obtain a red fluorescent diol RDB-OH;

[0054] Add 1.08 g of 4-fluorobenzophenone, 4.0 g of diethanolamine and 0.3 g of potassium hydroxide into a three-necked flask, stir with a magnetic stirrer, and raise the temperature to 90°C. After 24 hours of reaction, the reaction is finished; after cooling to room temperature, Add 50 ml of distilled water, ...

Embodiment 3

[0059] Add 1.6 g of rhodamine B and 30 ml of dichloromethane into a three-necked flask, stir until rhodamine B is completely dissolved, add 0.4 g of diethanolamine, 0.4 g of triethylamine, and 1.4 g of HBTU; react at room temperature under stirring with a magnetic stirrer After 10 hours, dilute with 60 ml of dichloromethane and wash with 40 ml of 1M sodium chloride aqueous solution for 5 times; after drying the organic phase with anhydrous magnesium sulfate, the dichloromethane is removed under vacuum; the crude product is reconstituted with ethanol After crystallization, it is placed in a vacuum oven and dried to a constant weight to obtain a red fluorescent diol RDB-OH;

[0060] Add 2.1 g of 4-fluorobenzophenone, 9 g of diethanolamine and 0.8 g of potassium hydroxide into a three-necked flask, stir with a magnetic stirrer, and raise the temperature to 110°C. After 15 hours of reaction, the reaction is finished; after cooling to room temperature, Add 90 ml of distilled water, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com