Lithium-ion power battery anode material lithium manganate and preparation method thereof

A material lithium manganese oxide, power battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of reduced electrical properties of materials, low material tap density, high degree of oxygen defects, etc., to improve lattice parameters, improve Stability and improvement of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

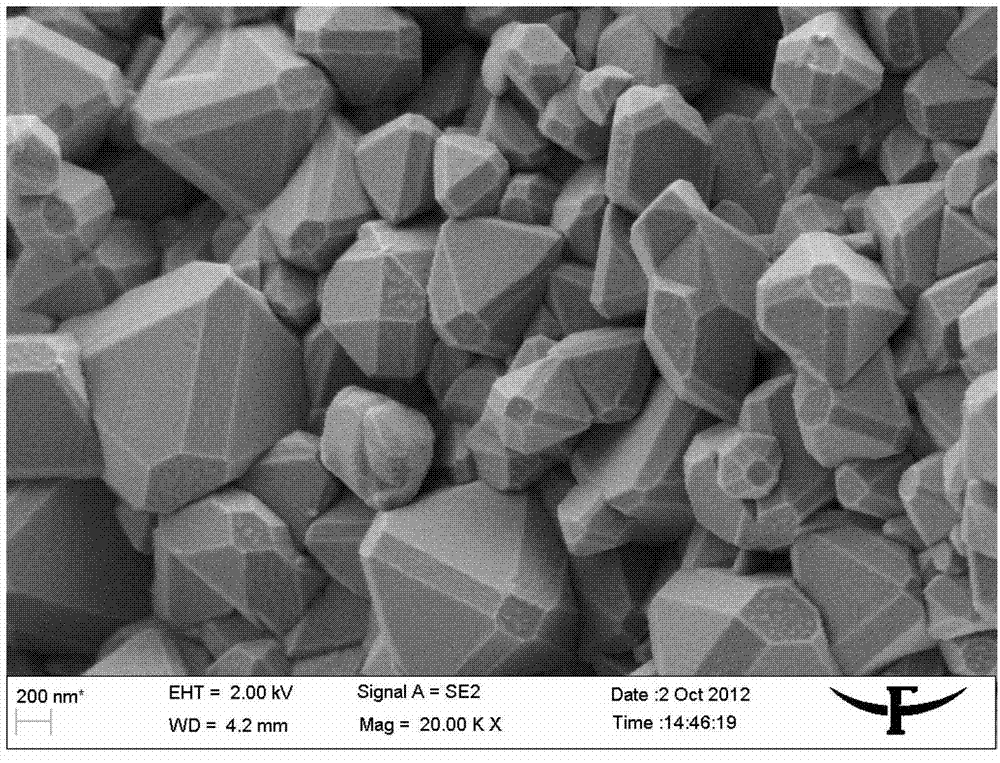

[0031] Lithium ion power battery cathode material lithium manganate of the present embodiment, molecular formula is Li 1.05 mn 1.9 Ta 0.1 o 4 / 0.5Al 2 o 3 .

[0032] The preparation method of the lithium ion power battery positive electrode material lithium manganate of the present embodiment, the steps are as follows:

[0033] 1) Weigh lithium carbonate, manganese sulfate, and tantalum pentoxide according to the molar ratio of lithium: manganese: tantalum 1.05:1.9:0.1, mix well and ball mill at 300r / min for 5h;

[0034] 2) Carry out the high-temperature roasting of the precursor of step 1) ball milling, keep it at 600°C for 10 hours, then raise the temperature to 800°C and keep it for 20 hours at a heating rate of 3°C / min, pass through a 300-mesh sieve after cooling down;

[0035] 3) Add the sieved particles and deionized water in step 2) into the reaction kettle according to the mass ratio of 1:5, ultrasonically disperse and stir, and keep the temperature of the water ...

Embodiment 2

[0042] Lithium ion power battery cathode material lithium manganate of the present embodiment, molecular formula is Li 1.1 mn 1.8 Ta 0.2 o 4 / 1.0Al 2 o 3 .

[0043] The preparation method of the lithium ion power battery positive electrode material lithium manganate of the present embodiment, the steps are as follows:

[0044]1) Weigh lithium nitrate, manganese nitrate and tantalum nitrate according to the molar ratio of lithium: manganese: tantalum 1.1:1.8:0.2, mix well and ball mill at 400r / min for 6h;

[0045] 2) Roast the precursor of ball milling in step 1) at high temperature, hold at 500°C for 11 hours, then raise the temperature to 850°C for 30 hours at a heating rate of 4°C / min, pass through a 300-mesh sieve after cooling down;

[0046] 3) Add the sieved particles in step 2) and absolute ethanol into the reaction kettle according to the mass ratio of 1:6.5, ultrasonically disperse and stir, and keep the temperature of the water bath at 55°C;

[0047] 4) During ...

Embodiment 3

[0052] Lithium ion power battery cathode material lithium manganate of the present embodiment, molecular formula is Li 1.2 mn 1.95 Ta 0.05 o 4 / 0.1Al 2 o 3 .

[0053] The preparation method of the lithium ion power battery positive electrode material lithium manganate of the present embodiment, the steps are as follows:

[0054] 1) Weigh lithium acetate, manganese acetate, and tantalum nitrate according to the molar ratio of lithium: manganese: tantalum 1.2:1.95:0.05, mix well and ball mill at 350r / min for 8h;

[0055] 2) The precursor of step 1) ball milling is roasted at high temperature, kept at 400°C for 12 hours, then raised to 900°C for 25 hours at a heating rate of 5°C / min, and passed through a 300-mesh sieve after cooling down;

[0056] 3) Add the mixed solution of the particles sieved in step 2), deionized water and absolute ethanol to the reaction kettle at a mass ratio of 1:8, ultrasonically disperse and stir, and keep the temperature of the water bath at 53°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com