Polypyrrole/ferrite/multi-wall carbon nanotube composite material preparation method

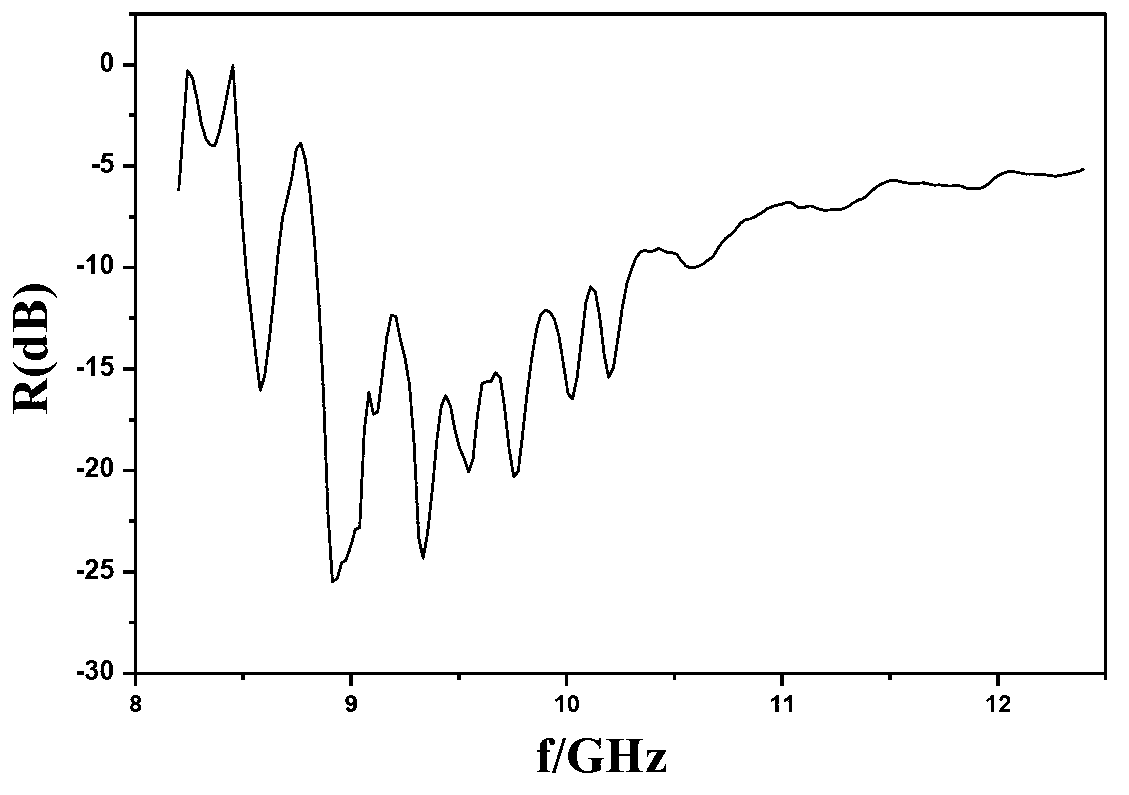

A technology of multi-wall carbon nanotubes and composite materials, which is applied in the field of preparation of polypyrrole/ferrite/multi-wall carbon nanotube composite materials, and can solve problems such as poor wave-absorbing performance, small wave-absorbing loss, and low electrical conductivity. problem, to achieve the effect of broadening the microwave absorption frequency band, good microwave absorption performance, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

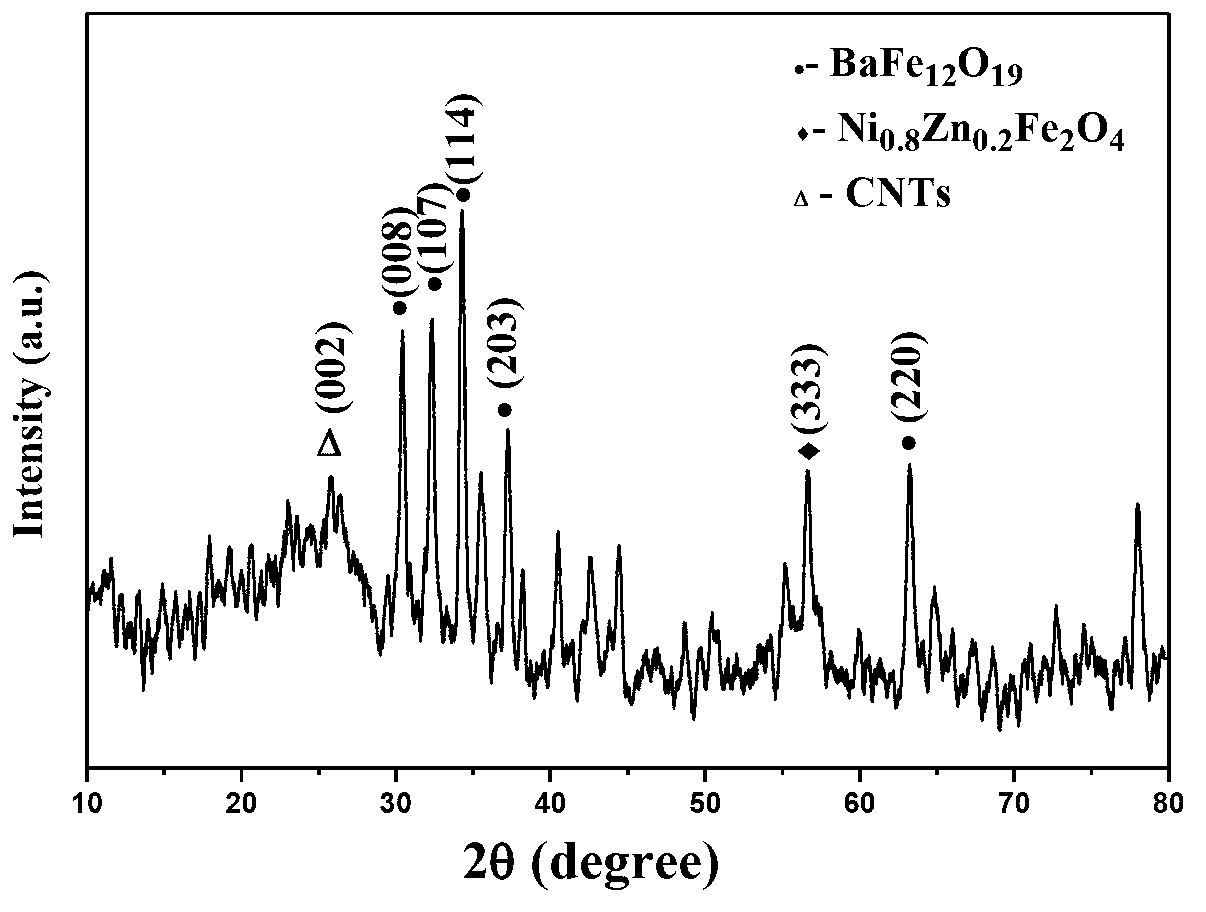

[0019] (1) BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 Preparation of:

[0020] (a) Dissolve citric acid, iron nitrate, nickel nitrate, zinc nitrate, and barium nitrate with a molar ratio of 217:76:4:1:6 in deionized water, and magnetically stir evenly at room temperature;

[0021] (b) ethylene glycol with a molar ratio of 2 times citric acid is added to the solution, and then the pH is adjusted to 7 with ethylenediamine;

[0022](c) under magnetic stirring, the obtained solution is heated to 75° C., and the water is evaporated until a gel is formed;

[0023] (d) The gel was first dried in an oven at 120 °C for 24 h, then transferred to a muffle furnace at 400 °C for pre-sintering for 3 h, and finally calcined at 1100 °C for 2 h to obtain BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 Ferrite powder.

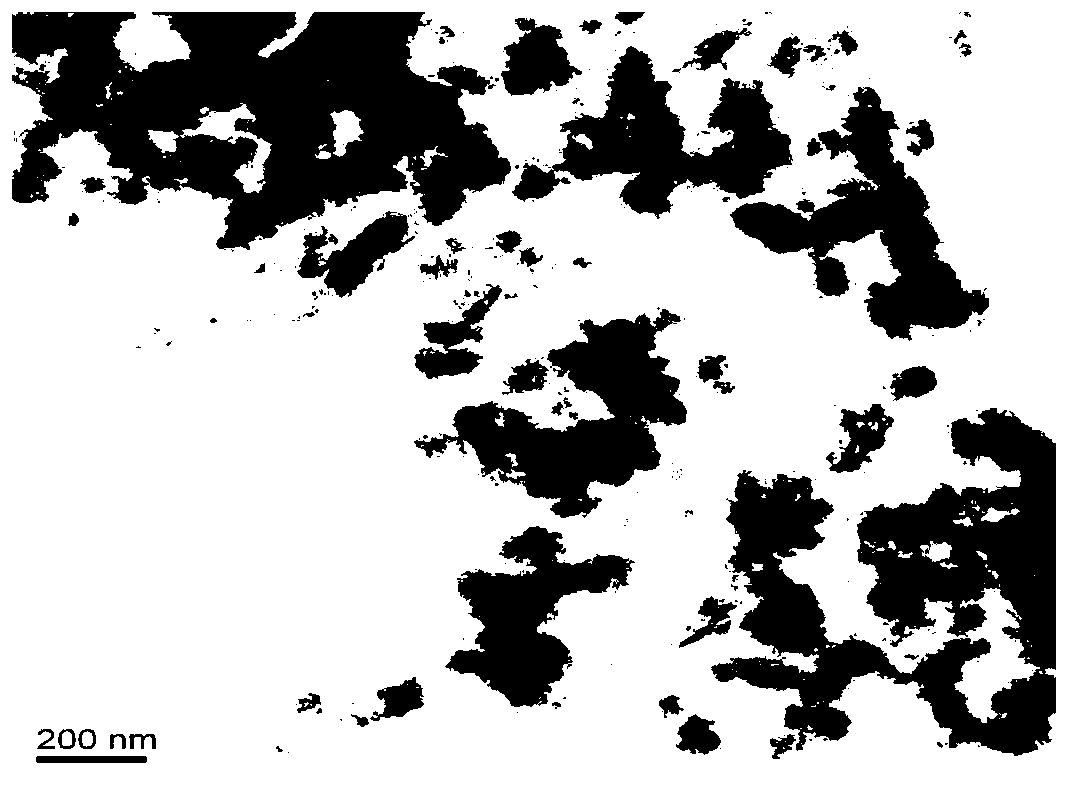

[0024] (2) Treatment of multi-walled carbon nanotubes:

[0025] (a) first calcining the multi-walled carbon nanotubes in a tube furnace at 600°C for 2h;

[0026] (b) Transfer to a...

Embodiment 2

[0035] (1) BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 Preparation of:

[0036] (a) Dissolve citric acid, iron nitrate, nickel nitrate, zinc nitrate, and barium nitrate with a molar ratio of 217:76:4:1:6 in deionized water, and magnetically stir evenly at room temperature;

[0037] (b) ethylene glycol with a molar ratio of 2 times citric acid is added to the solution, and then the pH is adjusted to 7 with ethylenediamine;

[0038] (c) under magnetic stirring, the obtained solution is heated to 75° C., and the water is evaporated until a gel is formed;

[0039] (d) The gel was first dried in an oven at 120 °C for 24 h, then transferred to a muffle furnace at 400 °C for pre-sintering for 3 h, and finally calcined at 1100 °C for 2 h to obtain BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 Ferrite powder.

[0040] (2) Treatment of multi-walled carbon nanotubes:

[0041] (a) first calcining the multi-walled carbon nanotubes in a tube furnace at 600°C for 2h;

[0042] (b) Transfer to ...

Embodiment 3

[0051] (1) BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 Preparation of:

[0052] (a) Dissolve citric acid, iron nitrate, nickel nitrate, zinc nitrate, and barium nitrate with a molar ratio of 217:76:4:1:6 in deionized water, and magnetically stir evenly at room temperature;

[0053] (b) ethylene glycol with a molar ratio of 2 times citric acid is added to the solution, and then the pH is adjusted to 7 with ethylenediamine;

[0054] (c) under magnetic stirring, the obtained solution is heated to 75° C., and the water is evaporated until a gel is formed;

[0055] (d) The gel was first dried in an oven at 120 °C for 24 h, then transferred to a muffle furnace at 400 °C for pre-sintering for 3 h, and finally calcined at 1100 °C for 2 h to obtain BaFe 12 o 19 -Ni 0.8 Zn 0.2 Fe 2 o 4 Ferrite powder.

[0056] (2) Treatment of multi-walled carbon nanotubes:

[0057] (a) first calcining the multi-walled carbon nanotubes in a tube furnace at 600°C for 2h;

[0058] (b) Transfer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com