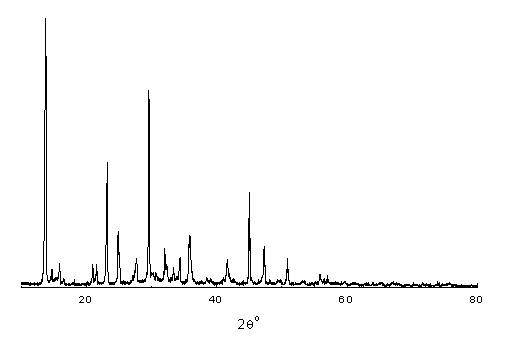

Process for preparing trihydrate magnesium carbonate crystal whiskers through microwave method

A technology of magnesium carbonate trihydrate and microwave method, which is applied in the field of mineral processing, can solve the problems of low yield of magnesium carbonate trihydrate whiskers, high energy consumption, long reaction time, etc., and achieve high yield, energy saving and environmental protection, The effect of short reaction times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

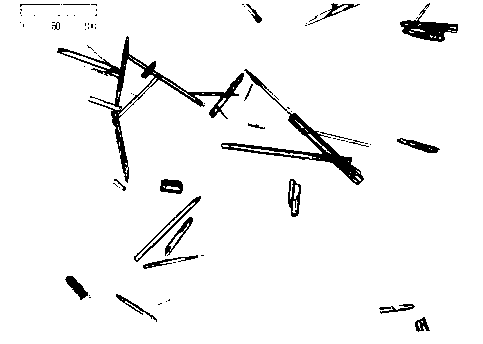

Embodiment 1

[0022] (1) Take the magnesium chloride hexahydrate solution with a concentration of 0.3mol / L into the reaction tank, add the ammonium carbonate solution with a concentration of 0.4mol / L into the magnesium chloride hexahydrate solution within 10s at room temperature, and the mixture of magnesium chloride hexahydrate and ammonium carbonate The molar ratio of the added amount is 1:1.3, while stirring, the stirring speed is 100r / min, and the stirring is continued for 2~3 minutes after the solution is mixed;

[0023] (2) Move the reaction tank containing the mixed material to the microcomputer microwave chemical reactor, and continue stirring during the reaction process. After reacting for 10 minutes under the condition of stirring rate of 80r / min and microwave power of 240W, stop the reaction and wait for microwave After the temperature of the reactor is lowered to room temperature, the reaction slurry in the reaction tank is centrifuged and dehydrated in a low-speed centrifuge, an...

Embodiment 2

[0028] (1) Take the magnesium chloride hexahydrate solution with a concentration of 0.5mol / L into the reaction tank, add the ammonium carbonate solution with a concentration of 1.1mol / L into the magnesium chloride hexahydrate solution within 8s at room temperature, the magnesium chloride hexahydrate and ammonium carbonate The molar ratio of the added amount is 1:1.2, while stirring, the stirring speed is 200r / min, and the stirring is continued for 2~3 minutes after the solution is mixed;

[0029] (2) Move the reaction tank containing the mixed material to a microcomputer microwave chemical reactor, and continue to stir during the reaction. After reacting for 7 minutes under the condition of stirring rate of 100r / min and microwave power of 360W, stop the reaction and wait for microwave After the temperature of the reactor is lowered to room temperature, the reaction slurry in the reaction tank is centrifuged and dehydrated in a low-speed centrifuge, and the obtained solid produc...

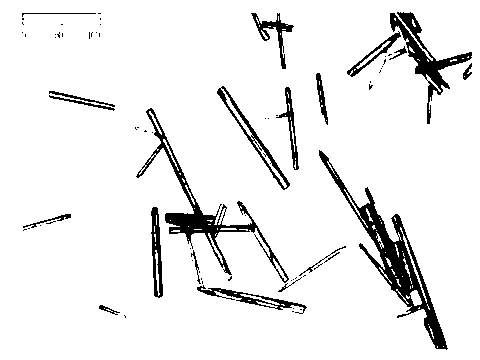

Embodiment 3

[0034] (1) Take the magnesium chloride hexahydrate solution with a concentration of 0.6mol / L into the reaction tank, add the ammonium carbonate solution with a concentration of 1.5mol / L to the magnesium chloride hexahydrate solution within 5s at room temperature, the magnesium chloride hexahydrate and ammonium carbonate Add the molar ratio of 1:1.5, stir at the same time, the stirring speed is 500r / min, and continue to stir for 2~3 minutes after the solution is mixed;

[0035] (2) Move the reaction tank containing the mixed material to the microcomputer microwave chemical reactor, and continue to stir during the reaction process. After reacting for 5 minutes under the condition of stirring rate of 150r / min and microwave power of 480W, stop the reaction and wait for microwave After the temperature of the reactor is lowered to room temperature, the reaction slurry in the reaction tank is centrifugally dehydrated in a low-speed centrifuge, and the obtained solid product is washed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com