{110} surface exposed titanium dioxide photocatalysis material and preparation method thereof

A photocatalytic material, titanium dioxide technology, applied in the field of photocatalysis, achieves the effects of mild conditions, good repeatability, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add secondary water, hydrogen peroxide and hydrofluoric acid into the polytetrafluoroethylene lining of the reaction kettle so that the concentrations of hydrogen peroxide and hydrofluoric acid are 2.4 mol / L and 0.1 mol / L, respectively. Then, add 1.2×10 -4 mol of titanium trichloride, stirred evenly, put the mixture in a high-pressure reactor, put it in an oven at 180°C, and react for 18 hours.

[0020] After the reaction kettle was cooled to room temperature, the supernatant was absorbed and discarded. The lower precipitate was centrifuged and washed 6 times with secondary water. After washing, the precipitate was dried in a 60° C. oven for 12 hours under vacuum to obtain an anatase titanium dioxide photocatalyst with exposed {110} faces.

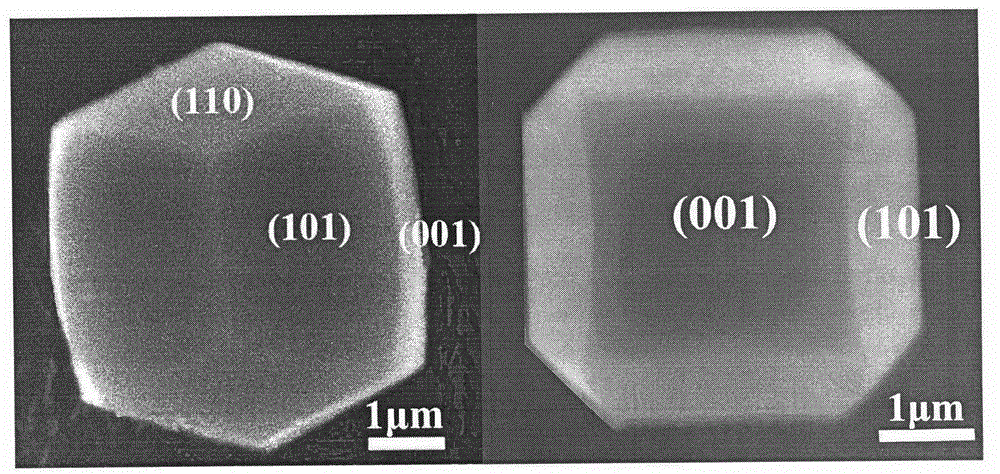

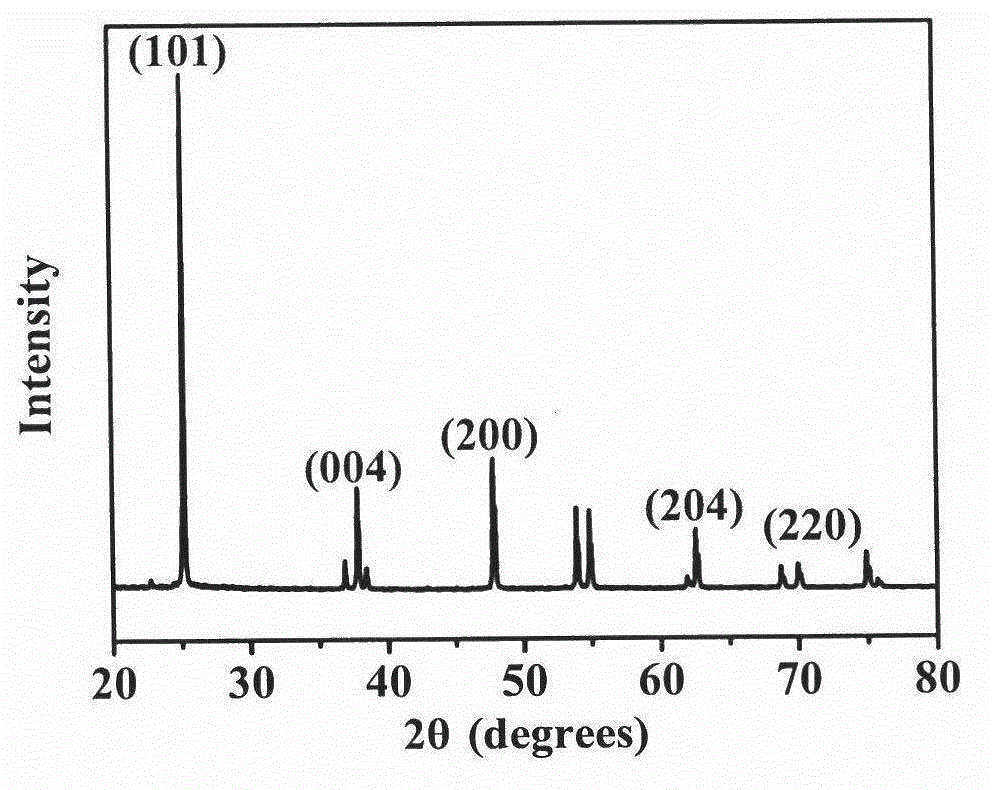

[0021] The different angles scanning electron microscope picture of embodiment 1 gained product is as figure 1 As shown, it can be seen from the figure that the crystal surfaces of the obtained products can be divided into three ...

Embodiment 2

[0024] Add secondary water, hydrogen peroxide and hydrofluoric acid into the polytetrafluoroethylene lining of the reaction kettle so that the concentrations of hydrogen peroxide and hydrofluoric acid are 1.5 mol / L and 0.1 mol / L, respectively. Then, add 1.2×10 -4 mol of titanium trichloride, stirred evenly, put the mixture in a high-pressure reactor, put it in an oven at 180°C, and react for 18 hours.

[0025] After the reaction kettle was cooled to room temperature, the supernatant was absorbed and discarded. The lower precipitate was centrifuged and washed 6 times with secondary water. After washing, the precipitate was dried in a 60°C oven for 12 hours under vacuum to obtain a titanium dioxide photocatalyst with a large {110} surface exposed.

Embodiment 3

[0027] Add secondary water, hydrogen peroxide and hydrofluoric acid into the polytetrafluoroethylene lining of the reactor so that the concentrations of hydrogen peroxide and hydrofluoric acid are 0.9mol / L and 0.1mol / L, respectively. Then, add 1.2×10 -4 mol of titanium trichloride, stirred evenly, put the mixture in a high-pressure reactor, put it in an oven at 180°C, and react for 18 hours.

[0028] After the reaction kettle was cooled to room temperature, the supernatant was absorbed and discarded. The lower precipitate was centrifuged and washed 6 times with secondary water. After washing, the precipitate was put into an oven at 60° C. for 12 hours in vacuum to dry to obtain a titanium dioxide photocatalyst with exposed {110} faces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com