Supported photocatalyst as well as preparation method and application thereof

A photocatalyst, supported technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of difficulty in degrading gas-phase organics, waste of catalyst, difficulty in recycling photocatalyst, etc., and achieve easy recovery. and reuse, improve degradation and mineralization efficiency, and uniform UV light distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

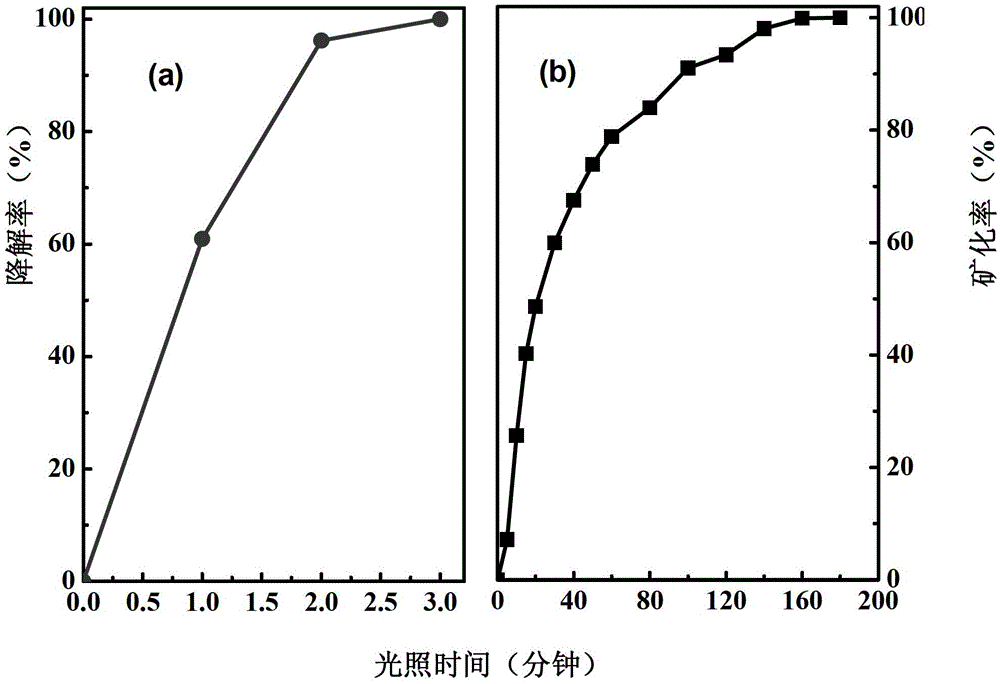

Examples

Embodiment 1

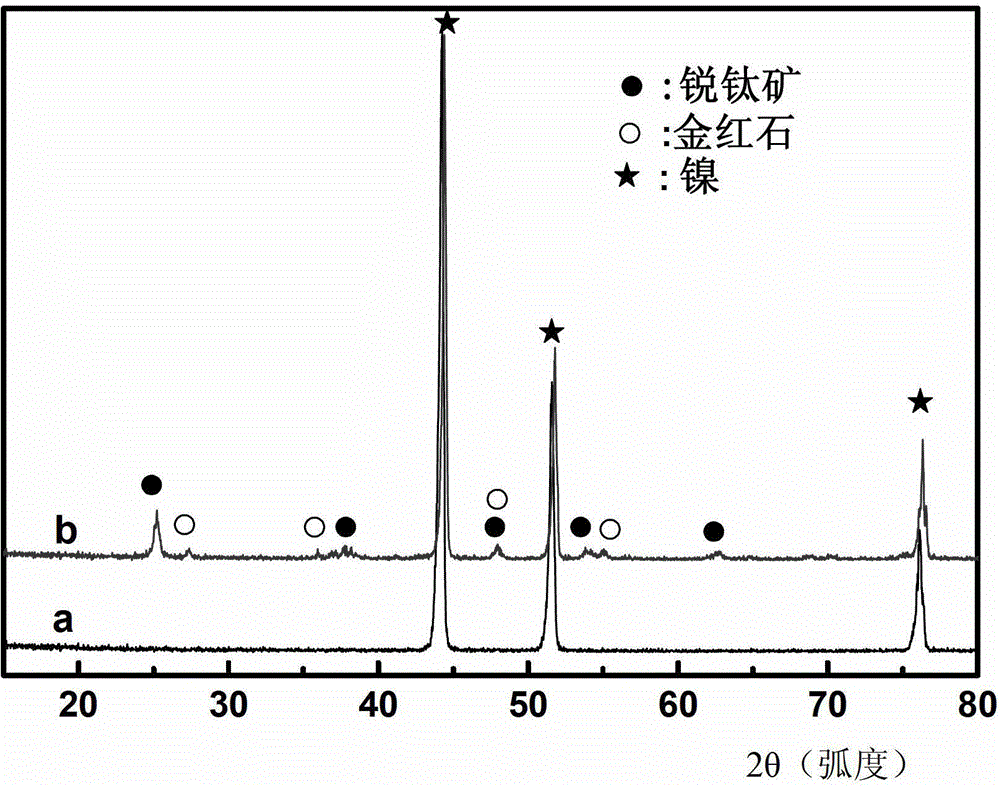

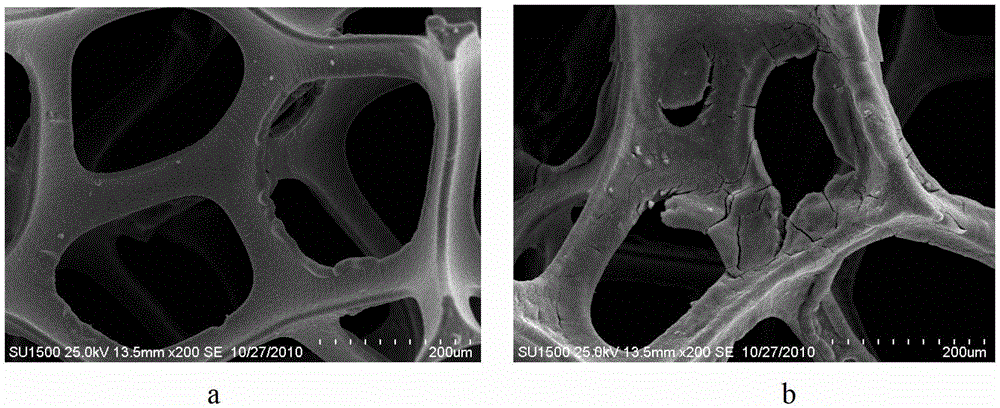

[0041] The preparation method of foam metal supported photocatalyst:

[0042] (1) Electrode pretreatment: Clean the nickel foam metal mesh (area size: 50mm×200mm) for 3 times in 0.1mol / L hydrochloric acid, and then ultrasonicate in absolute ethanol (ultrasonic instrument with a frequency of 40kHz) for 30min , and then washed 3 times with deionized water, dried at room temperature and used as electrode cathode; with the same ultrasonic frequency, the titanium sheet was ultrasonicated in acetone for 15 minutes, then placed in ethanol for 15 minutes, and finally cleaned with deionized water 3 times, after drying naturally at room temperature, it was used as an electrode anode.

[0043] (2) TiO 2 Sol Preparation: Nano TiO 2 Photocatalyst powder and deionized water were mixed at a ratio of 5:1000 (g:mL), fully stirred for 30 minutes, and then placed in an ultrasonic instrument with an ultrasonic frequency of 40 kHz for 15 minutes to obtain TiO 2 Sol.

[0044] (3) Preparation of...

Embodiment 2

[0048] (1) Electrode pretreatment: Clean the nickel foam metal mesh (area size: 100mm×400mm) for 3 times in 1.0mol / L hydrochloric acid, and then ultrasonicate in absolute ethanol (ultrasonic instrument with a frequency of 10kHz) for 100min , and then washed 3 times with deionized water, dried at room temperature and used as electrode cathode; with the same ultrasonic frequency, the graphite sheet was ultrasonicated in acetone for 15 minutes, then placed in ethanol for 15 minutes, and finally washed with deionized water 3 times, after drying naturally at room temperature, it was used as an electrode anode.

[0049] (2) TiO 2 Sol preparation: TiO 2 Photocatalyst powder and deionized water were mixed at a ratio of 5:500 (g:mL), fully stirred for 100 minutes, and then placed in an ultrasonic instrument with an ultrasonic frequency of 10 kHz for 30 minutes to obtain TiO 2 Sol.

[0050] (3) Preparation of supported photocatalyst by electrodeposition: immerse the pretreated nickel...

Embodiment 3

[0053] (1) Electrode pretreatment: Clean the foamed nickel metal mesh (area size: 100mm×400mm) for 3 times in 1.0mol / L hydrochloric acid, and then ultrasonicate in absolute ethanol (ultrasonic instrument with a frequency of 10kHz) 100min, then wash it with deionized water for 3 times, dry it at room temperature and use it as the electrode cathode; use the same ultrasonic frequency, after the graphite sheet is ultrasonicated in acetone for 15min, then put it in ethanol and ultrasonically for 15min, and finally use deionized water After washing 3 times, it was used as the electrode anode after being dried naturally at room temperature.

[0054] (2) TiO 2 Sol preparation: TiO 2 Photocatalyst powder and deionized water were mixed at a ratio of 0.1:200 (g:mL), fully stirred for 100 minutes, and then placed in an ultrasonic instrument with an ultrasonic frequency of 10 kHz for 30 minutes to obtain TiO 2 Sol.

[0055] (3) Preparation of supported photocatalyst by electrodeposition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com