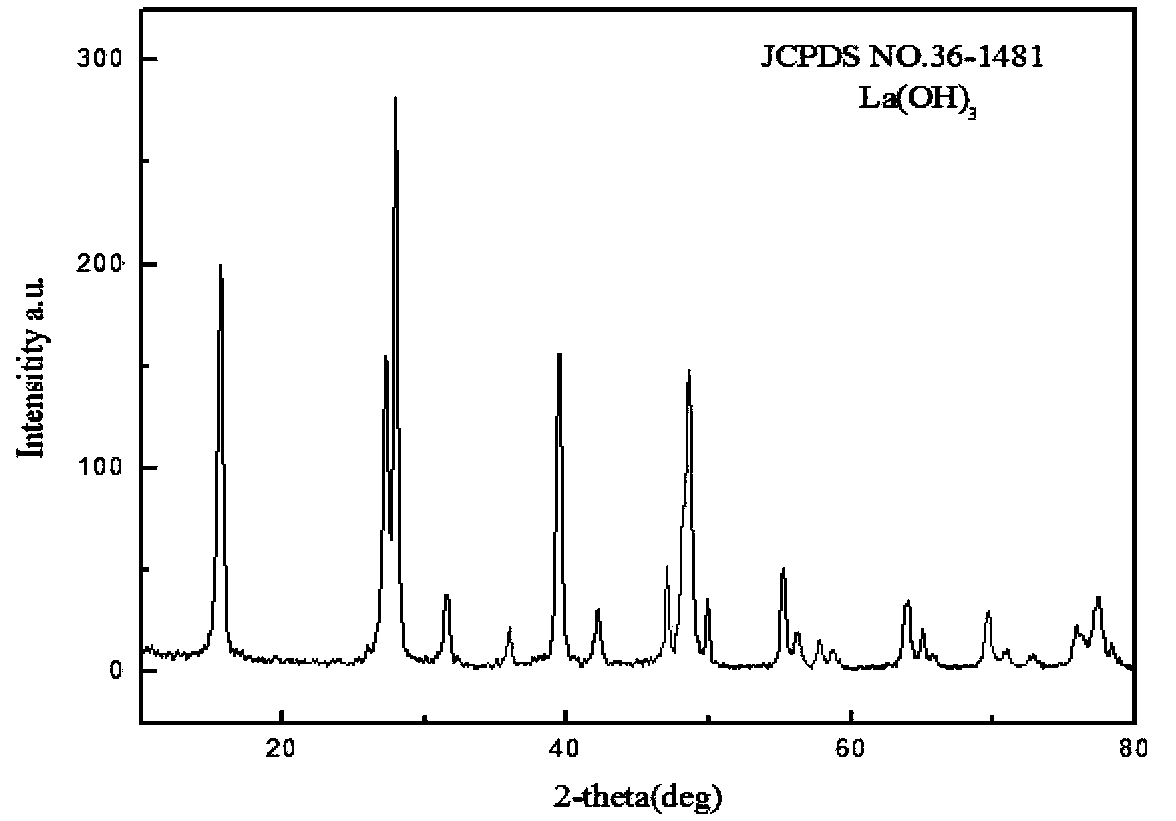

Preparation method of bar-shaped lanthanum hydroxide nanocrystal

A technology of lanthanum hydroxide and nanocrystals, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of long reaction time under experimental conditions, poor product dispersion, small specific surface area of samples, etc., and achieve low cost , small grain size and short reaction time period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) The analytically pure lanthanum sulfate nonahydrate (La 2 (SO 4 ) 3 9H 2 O) added to deionized water to make a transparent solution A with a concentration of 0.05mol / L;

[0022] 2) Add analytically pure ethylenediaminetetraacetic acid (EDTA) to solution A so that the concentration of EDTA in the solution is 0.005mol / L to obtain solution B;

[0023] 3) Add 1 mol / L ammonia solution dropwise to solution B to adjust the pH to 8.0, and magnetically stir to form precursor solution C;

[0024] 4) Pour the precursor solution C into a four-neck round bottom flask, put it into the UWave-1000 microwave-ultraviolet-ultrasonic trinity synthesis reaction instrument, select the combination of microwave heating and ultraviolet irradiation in the temperature-time mode, the The temperature of the temperature-time mode is controlled at 100°C, the reaction time is controlled at 10 minutes, and naturally cooled to room temperature after the reaction;

[0025] 5) The product was coll...

Embodiment 2

[0027] 1) The analytically pure lanthanum sulfate nonahydrate (La 2 (SO 4 ) 3 9H 2 O) added to deionized water to make a transparent solution A with a concentration of 0.01mol / L;

[0028] 2) Add analytically pure ethylenediaminetetraacetic acid (EDTA) to solution A so that the concentration of EDTA in the solution is 0.01mol / L to obtain solution B;

[0029] 3) Add 1 mol / L ammonia solution dropwise to solution B to adjust the pH to 9.0, and magnetically stir to form precursor solution C;

[0030] 4) Pour the precursor solution C into a four-neck round bottom flask, put it into the UWave-1000 microwave-ultraviolet-ultrasonic trinity synthesis reaction instrument, select the combination of microwave heating and ultraviolet irradiation in the temperature-time mode, the The temperature of the temperature-time mode is controlled at 120°C, the reaction time is controlled at 8 minutes, and the reaction is naturally cooled to room temperature after the end of the reaction;

[0031...

Embodiment 3

[0033] 1) The analytically pure lanthanum sulfate nonahydrate (La 2 (SO 4 ) 3 9H 2 O) added to deionized water to make a transparent solution A with a concentration of 0.3mol / L;

[0034] 2) Add analytically pure ethylenediaminetetraacetic acid (EDTA) to solution A so that the concentration of EDTA in the solution is 0.03mol / L to obtain solution B;

[0035] 3) Add 1 mol / L ammonia solution dropwise to solution B to adjust the pH to 10.0, and magnetically stir to form precursor solution C;

[0036] 4) Pour the precursor solution C into a four-neck round bottom flask, put it into the UWave-1000 microwave-ultraviolet-ultrasonic trinity synthesis reaction instrument, select the combination of microwave heating and ultraviolet irradiation in the temperature-time mode, the The temperature of the temperature-time mode is controlled at 140 ° C, the reaction time is controlled at 6 minutes, and naturally cooled to room temperature after the reaction is completed;

[0037] 5) The pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com