Co-production method for extracting bioactive substances from pig blood

A technology of biologically active substances and pig blood, applied in the field of separation and extraction of biologically active substances, can solve problems such as unsuitable for industrialized production, unqualified product yield and quality, complicated control of key variables and time, etc. The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

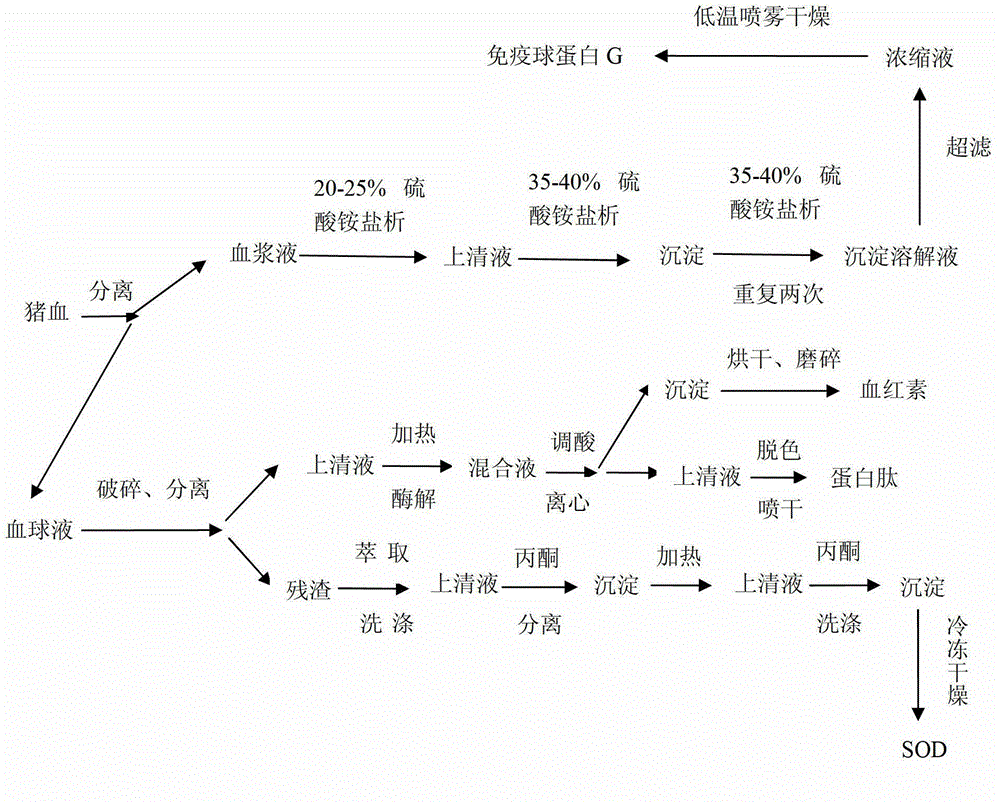

[0023] Example 1: A co-production method for extracting biologically active substances from pig blood, including the extraction of immunoglobulin G, the extraction of heme iron and protein peptides, and the extraction of SOD.

[0024] 1. Extraction of immunoglobulin G:

[0025] After 100kg of anticoagulant blood is separated, add 55kg of plasma to 55kg of PBS buffer for dilution, stir slowly and add 6.0kg of ammonium sulfate solid, the saturation reaches 20-25%, and adjust the pH of the plasma to 5.5, let it stand at room temperature for 30 minutes, and then collect it by pressure filtration 100L of supernatant; stir slowly in the supernatant and add 19.4kg of ammonium sulfate solid until the saturation reaches 35-40%, adjust the pH to 7.2, let stand for 30min, and press filter to collect the precipitate; add 50kg of pure water to dissolve the precipitate, add sulfuric acid 9.7kg of ammonium crystals, adjust the pH to 7.2, and then press filter to collect the precipitate; repe...

Embodiment 2

[0031] 1. Extraction of immunoglobulin G:

[0032]After separation of 5000kg anticoagulant original blood, add 2750kg of plasma to 2750kg of PBS buffer for dilution, stir slowly and add 320.0kg of ammonium sulfate solid, and adjust the pH of the plasma to 5.6. Slowly add 980kg of ammonium sulfate solid, adjust the pH to 7.4 and let it stand for 30 minutes to collect the precipitate by pressure filtration; add 2500 kg of pure water to dissolve the precipitate, add 490 kg of ammonium sulfate crystals to adjust the pH to 7.2, and then process for 30 minutes to collect the precipitate by pressure filtration; repeat the above One process twice, add 2500kg of pure water to dissolve the precipitate, then conduct ultrafiltration to concentrate and desalinate, the operating pressure is 0.15MPa, concentrate until no SO is detected 4 2- Low-temperature spray drying was carried out. The inlet temperature of the spray drying was 160°C, and the outlet temperature was 80°C. A total of 3.45k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com