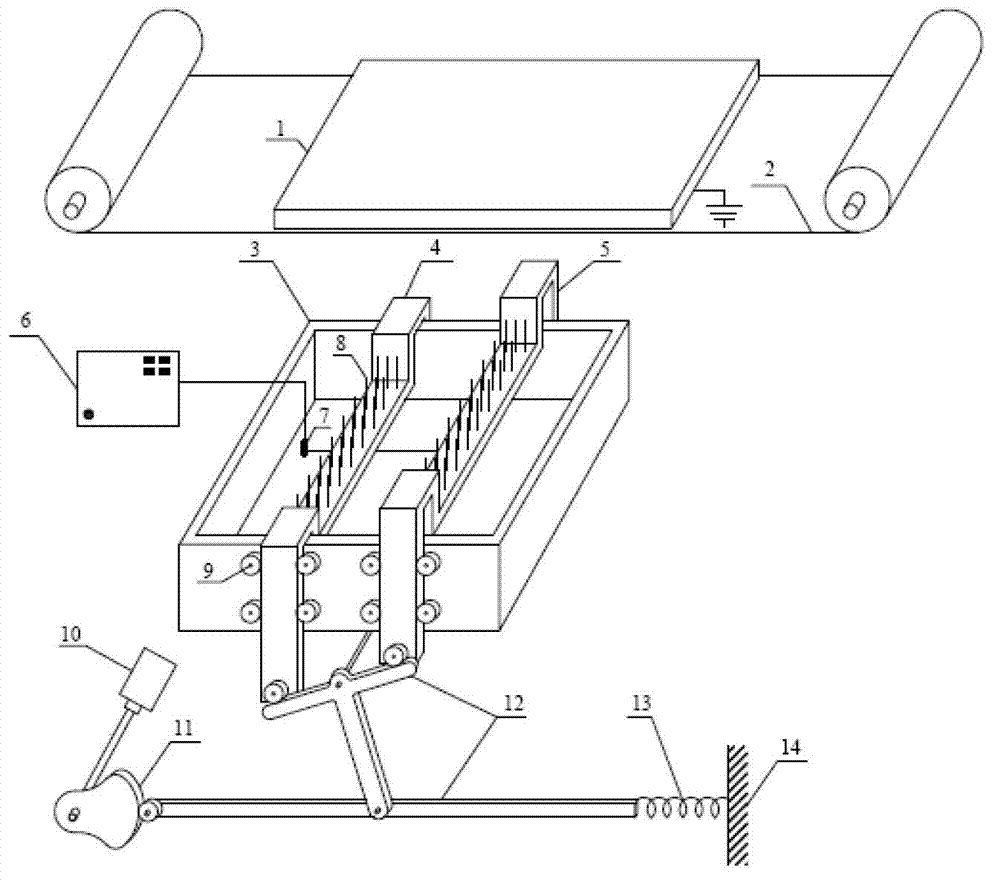

Device for preparing nanofibers on large scale by utilizing electrostatic spinning process and preparation method

An electrospinning process, nanofiber technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of single quality of nanofiber web, jet electrostatic interference, fixed number and position of needles, etc. The device has a simple structure, avoids needle blockage, and achieves the effect of morphological structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The polyacrylonitrile (PAN) (M w =100,000g·mol -1 ) Dissolved in N,N-dimethylformamide (DMF) to prepare a spinning solution with a concentration of 15wt%; in an environment with room temperature and relative humidity of 35%, inject the spinning solution into the storage tank , The metal electrode at the bottom of the reservoir is connected to the positive electrode of the high-voltage generator, the applied voltage is 10kV, the receiving distance (the distance between the spinneret and the base material layer) is 10cm, and the spinning time is 8h. Under this condition, electrostatic After spinning, a uniform nanofiber web attached to the surface of the base material was obtained, and the nanofiber web was peeled off. The square meter weight of the nanofiber web was measured to be about 51.85g·m -2 .

Embodiment 2

[0058] Dissolve polyvinyl alcohol (PVA) 1788 type powder in distilled water at 70°C to form a spinning solution with a concentration of 16wt%; in an environment with room temperature and relative humidity of 55%, pour the spinning solution into the storage tank The metal electrode at the bottom of the reservoir is connected to the positive electrode of the high-voltage generator, the applied voltage is 14kV, the receiving distance (the distance between the spinneret and the base material layer) is 14cm, and the spinning time is 10h. Electrospinning obtains a uniform nanofiber network attached to the surface of the base material. After peeling it off, the square meter weight of the nanofiber network is about 73.61g·m. -2 .

Embodiment 3

[0060] Put polyethylene oxide (PEO) (M w =3×10 5 g·mol -1 1) Dissolve in distilled water at 60°C to prepare a spinning solution with a concentration of 13wt%; in an environment of room temperature and relative humidity of 45%, inject the spinning solution into the storage tank, and the metal electrode at the bottom of the storage tank Connected to the positive pole of the high-voltage generator, the applied voltage is 12kV, the receiving distance (the distance between the spinneret and the base material layer) is 12cm, and the spinning time is 9h. Electrospinning is carried out under these conditions to obtain adhesion to the substrate The uniform nanofiber network on the surface of the material is peeled off, and the measured weight per square meter of the nanofiber network is about 54.88g·m -2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com